Method for removing nitrogen phosphorus from sludge fermentation liquid to improve organic acid recycling effect

A fermentation broth, organic acid technology, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve unreported problems, reduce pollution, reduce usage, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 0.8L of excess sludge and add it to the reactor. The total suspended solid concentration of the excess sludge is 32000mg / L, and the volatile solid concentration is 13000mg / L; use a pH meter to detect the pH change in the reactor in real time and control the reaction The pH value of the remaining sludge in the reactor is 9, and the temperature of the reactor is 40°C;

[0027] (2) After 20 days of anaerobic fermentation of the remaining sludge, take a sludge sample and centrifuge at 5000 rpm for 15 minutes to obtain 100 mL of supernatant, which contains 114 mg COD / gVSS of organic acid, 43 mg of ammonia nitrogen, and 14 mg of orthophosphate;

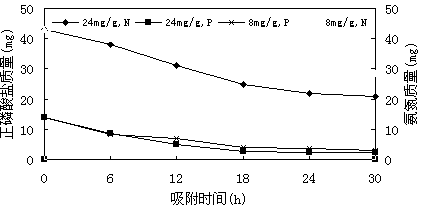

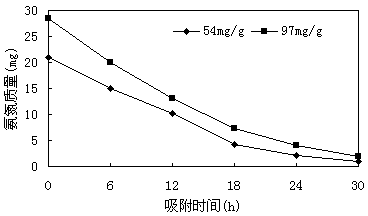

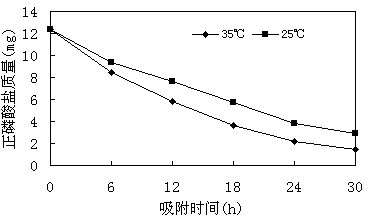

[0028] (3) Control the supernatant at pH=9, add 0.583g of alkali residue modified by sodium hydroxide alkali washing to the supernatant, and control the mass ratio of alkali residue to orthophosphate to 24mg orthophosphate / g alkali slag, after reacting at 35°C for 24 hours, the quality of orthophosphate was reduced to ...

Embodiment 2

[0031] (1) Take 0.8L of excess sludge and add it to the reactor. The total suspended solid concentration of the excess sludge is 32000mg / L, and the volatile solid concentration is 13000mg / L; use a pH meter to detect the pH change in the reactor in real time and control the reaction The pH value of the remaining sludge in the reactor is 9, and the temperature of the reactor is 40°C;

[0032] (2) After 20 days of anaerobic fermentation of the remaining sludge, take a sludge sample and centrifuge at 5000 rpm for 15 minutes to obtain 100 mL of supernatant, which contains 114 mg COD / gVSS of organic acid, 43 mg of ammonia nitrogen, and 14 mg of orthophosphate;

[0033] (3) Control the supernatant at pH=9, add 1.75g of alkali residue modified by sodium hydroxide alkali washing to the supernatant, and control the mass ratio of alkali residue to orthophosphate to 8mg orthophosphate / g alkali slag, after reacting at 35°C for 30 hours, the mass of orthophosphate was reduced to 3.1 mg...

Embodiment 3

[0036] (1) Take 0.8L of excess sludge and add it to the reactor. The total suspended solid concentration of the excess sludge is 24000mg / L, and the volatile solid concentration is 10200mg / L; use a pH meter to detect the pH change in the reactor in real time and control the reaction The pH value of the remaining sludge in the reactor is 10, and the temperature of the reactor is 35°C;

[0037] (2) After the remaining sludge was anaerobically fermented for 15 days, the sludge sample was taken and centrifuged at 5000 rpm for 15 minutes to obtain 100 mL of supernatant, which contained 101.6 mg COD / gVSS of organic acid, 36 mg of ammonia nitrogen, and 12.4 mg of orthophosphate;

[0038](3) Control the supernatant at pH=10, add 0.517g of alkali residue modified by sodium hydroxide alkali washing to the supernatant, and control the mass ratio of alkali residue to orthophosphate to 24mg orthophosphate / g alkali slag, after reacting at 35°C for 24 hours, the mass of orthophosphate w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap