Strip steel surface flame cleaning method and apparatus thereof

A flame cleaning and strip steel technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as low heat and mass transfer coefficients, long cleaning sections, and large temperature differences in strip steel, and achieve uniform cleaning of oil pollution and simplification. Function, uniform burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

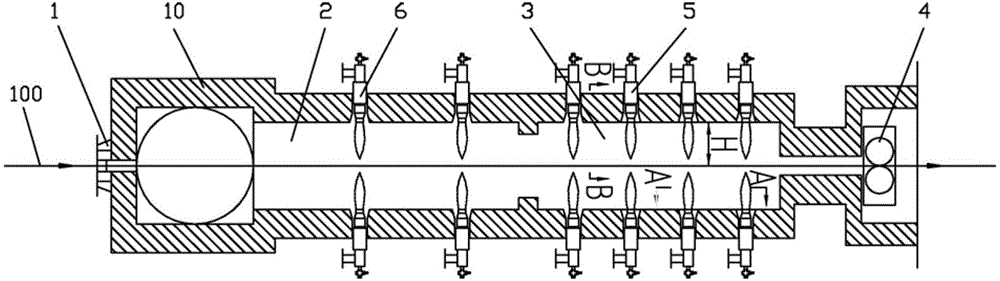

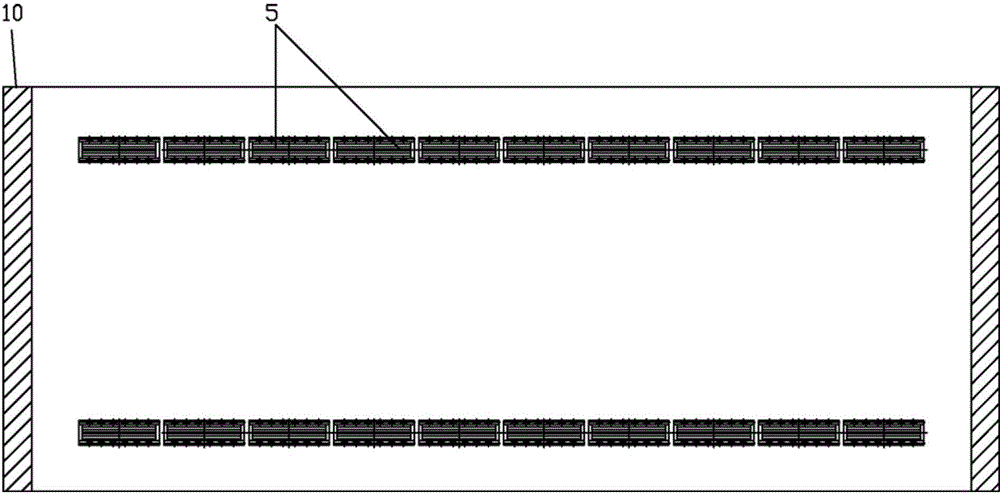

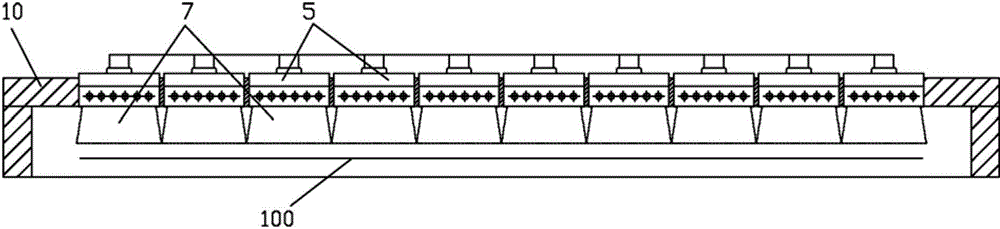

[0055] see Figure 1 to Figure 5 , the strip steel surface flame cleaning device of the present invention is a strip steel heat treatment furnace, the body of furnace 10 is provided with an inlet seal 1, a flue gas preheating section 2, a direct fire cleaning preheating section 3, and an outlet seal 4; the furnace body is cleaned by direct fire A plurality of burners 5 are arranged along the width of the steel strip above or / and below the wide surface of the rectangular hearth of the preheating section 3, and the nozzles of the burners 5 are slit strips that can form uniform strip flames.

[0056] Again, described burner 5 is box-shaped structure, and spout 51 is slit type, and spout width is B, and the distance of spout to steel strip is H, then has H / B=5~15, and air-fuel ratio n=0.8~ 1.0.

[0057] Several supplementary burners 6 are arranged along the width of the steel strip on the upper or / and lower surface of the rectangular furnace of the flue gas preheating section 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com