Paper shredding device for hydrapulper

A hydraulic pulper and paper shredding technology, applied in the direction of raw material separation, etc., can solve problems such as low percussion degree, pulper jamming, motor burnout, etc., to improve flatness and smoothness, speed up pulping speed, improve percussion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

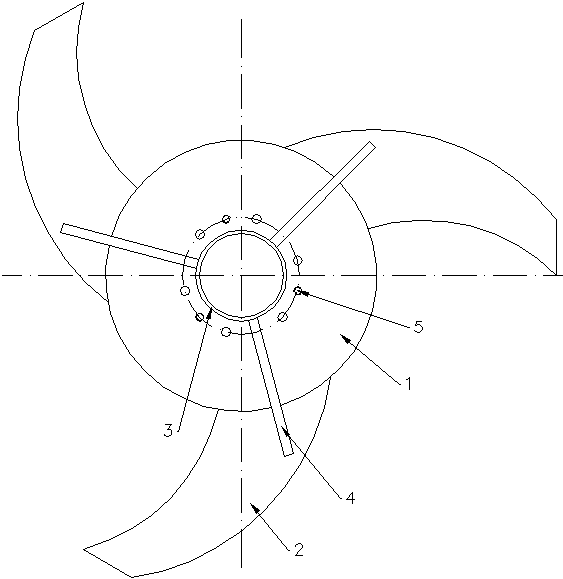

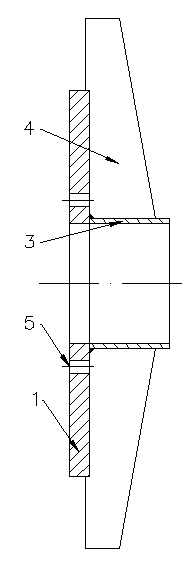

[0015] Such as Figure 1 ~ Figure 2 As shown, the shredding device used in the hydraulic pulper provided by this embodiment includes a cutter head 1, and the outer ring of the cutter head 1 is fixedly connected with three shredding knives 2 uniformly distributed in the circumferential direction. The inner side and the outer side of the knife 2 are arc lines, and a cover 3 is fixedly connected to the cutterhead 1, the central axis of the cover 3 is collinear with the central axis of the cutterhead 1, and the outer ring of the cover 3 There are three baffles 4 evenly distributed in the circumferential direction fixedly connected, a part of the bottom surface of the baffle 4 close to the cover 3 is fixedly connected with the cutterhead 1, and the rest is fixedly connected with the shredder knife 2, and the baffles 4 and the height of the fixed end of the sleeve cover 3 are twice the height of the other end of the baffle, and the cutter head 1 is provided with a threaded hole 5 fo...

Embodiment 2

[0018] In the present embodiment, the structure is the same as that in Example 1, and the pulper with a volume of 35 m3 is selected, wherein the diameter of the cutter head is 995 mm, the thickness of the cutter head is 55 mm, and the thickness of the shredder is 50 mm. The distance from the central axis to the outermost end of the baffle is 640mm, and the distance from the inner side of the shredder away from the cutter head to the outer ring of the cutter head is 635mm, which also increases the line speed by 5-6m per second, and can generate a strong force during operation. The vortex drags the material towards the shredder, where it is quickly crushed by the shredder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com