Method for measuring aero-engine compressor blades based on three-coordinate measuring machine

A three-coordinate measuring machine and aero-engine technology, applied in the field of measurement, can solve problems such as low measurement efficiency, and achieve the effect of improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

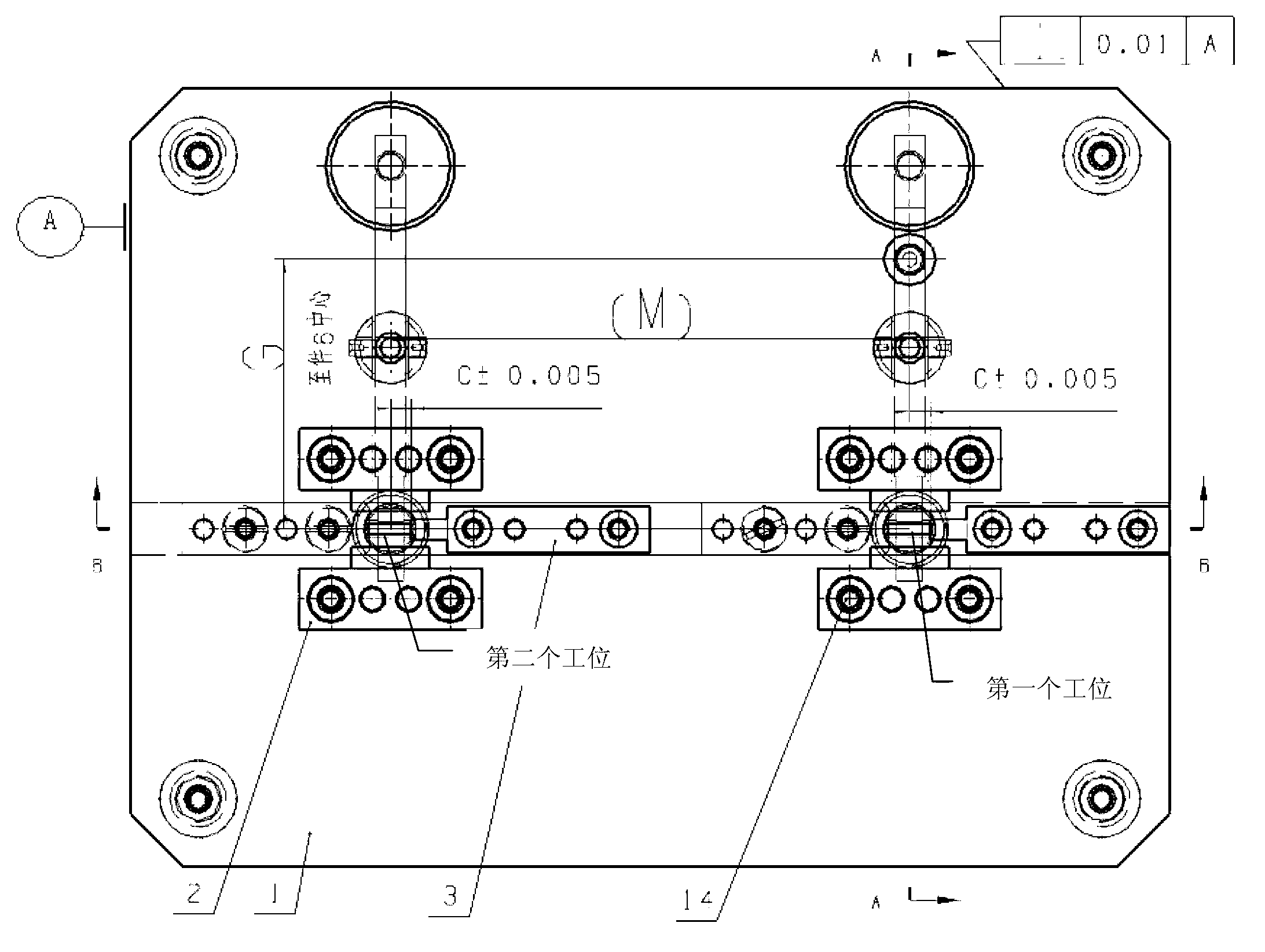

[0056] (1) Make a measuring fixture

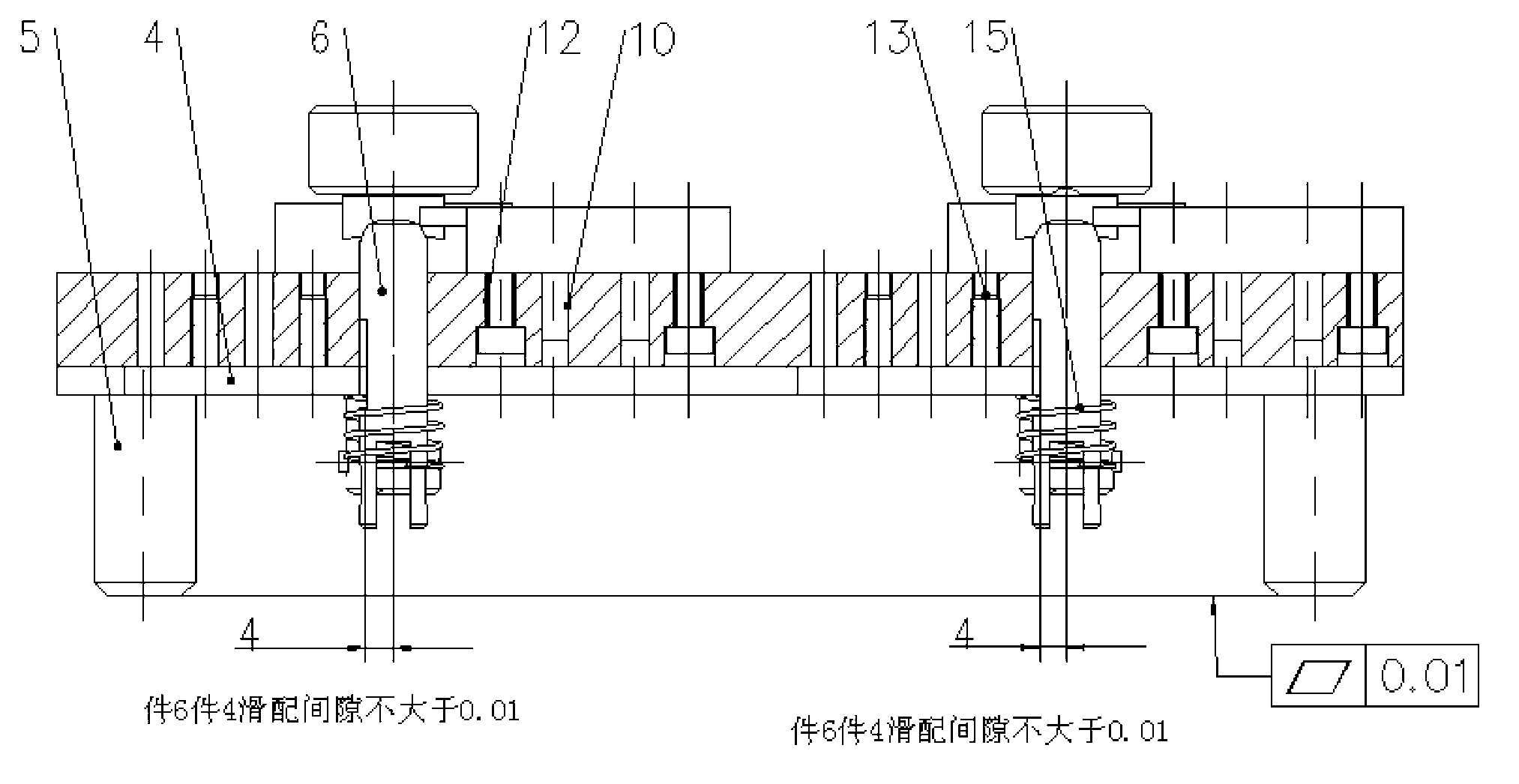

[0057] The measuring fixture consists of a base plate 1 and two sets of pressing devices and positioning devices of the same structure. The two sets of pressing devices and positioning devices are respectively located on both sides of the center line of the base plate, with one side of the base plate 1 as the reference plane, and the adjacent sides The verticality is within 0.01mm.

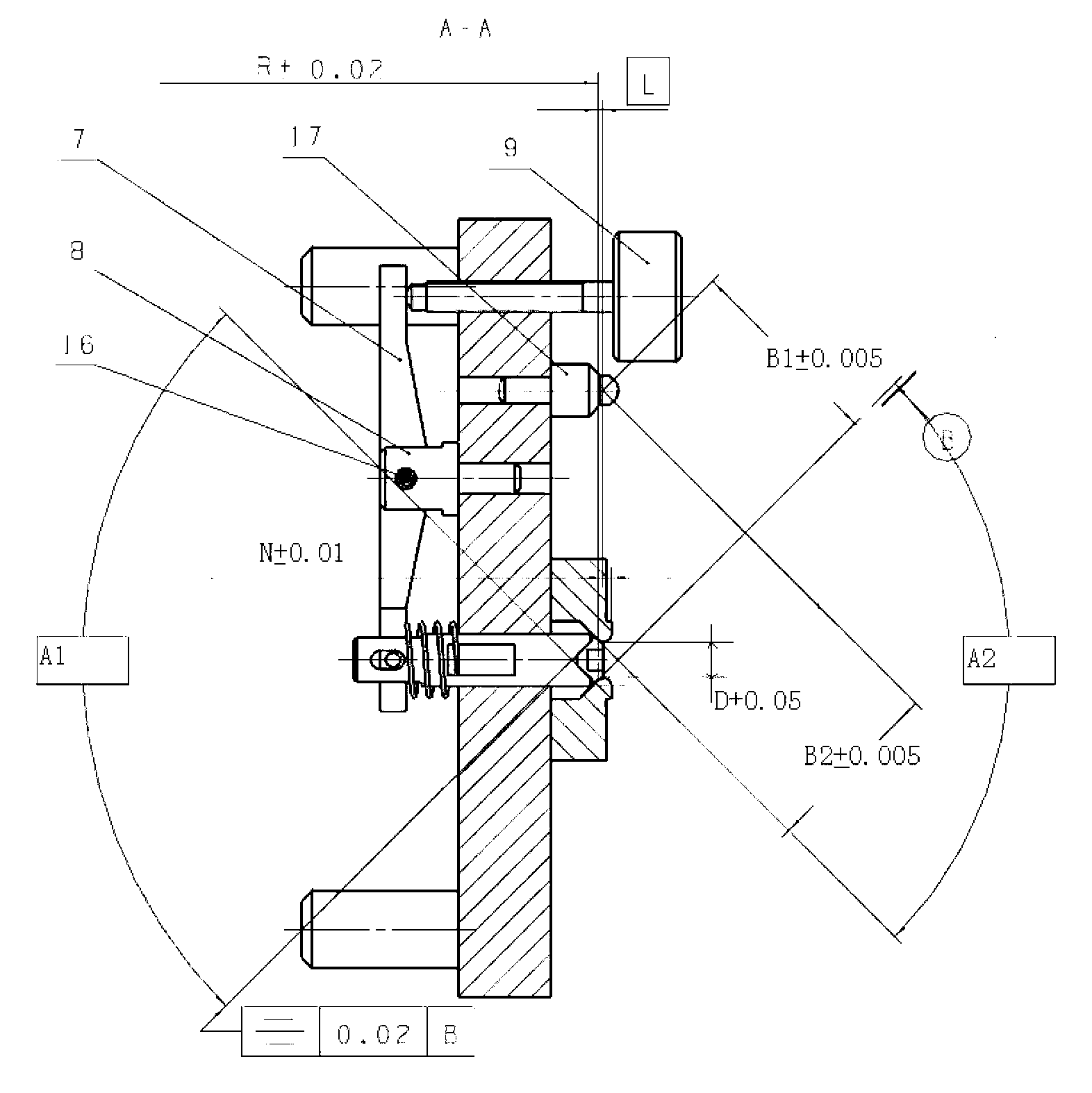

[0058] Each set of pressing device includes a support pin 6, a lever 7, a lever support 8, a limit screw 9, a cylindrical pin 10 and a spring 15, the support pin 6 penetrates the upper and lower surfaces of the base plate, and the support pin 6 is located on the pin rod on the lower surface of the base plate Sleeve spring 15, the end of support pin 6 located on the upper surface of the base plate has a V-shaped groove, the angle between the two sides of the V-shaped groove is 90°, the spring 15 is stuck between the lower surface of the base plate 1 and the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com