Detection method of polyacrylamide concentration in tertiary oil recovery liquid

A technology of polyacrylamide and concentration detection, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the influence of chemical indicators. It can solve the problems of different polymer molecular weights, production fluid errors, polymer Concentration detection has a great influence, and achieve the effect of eliminating errors and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

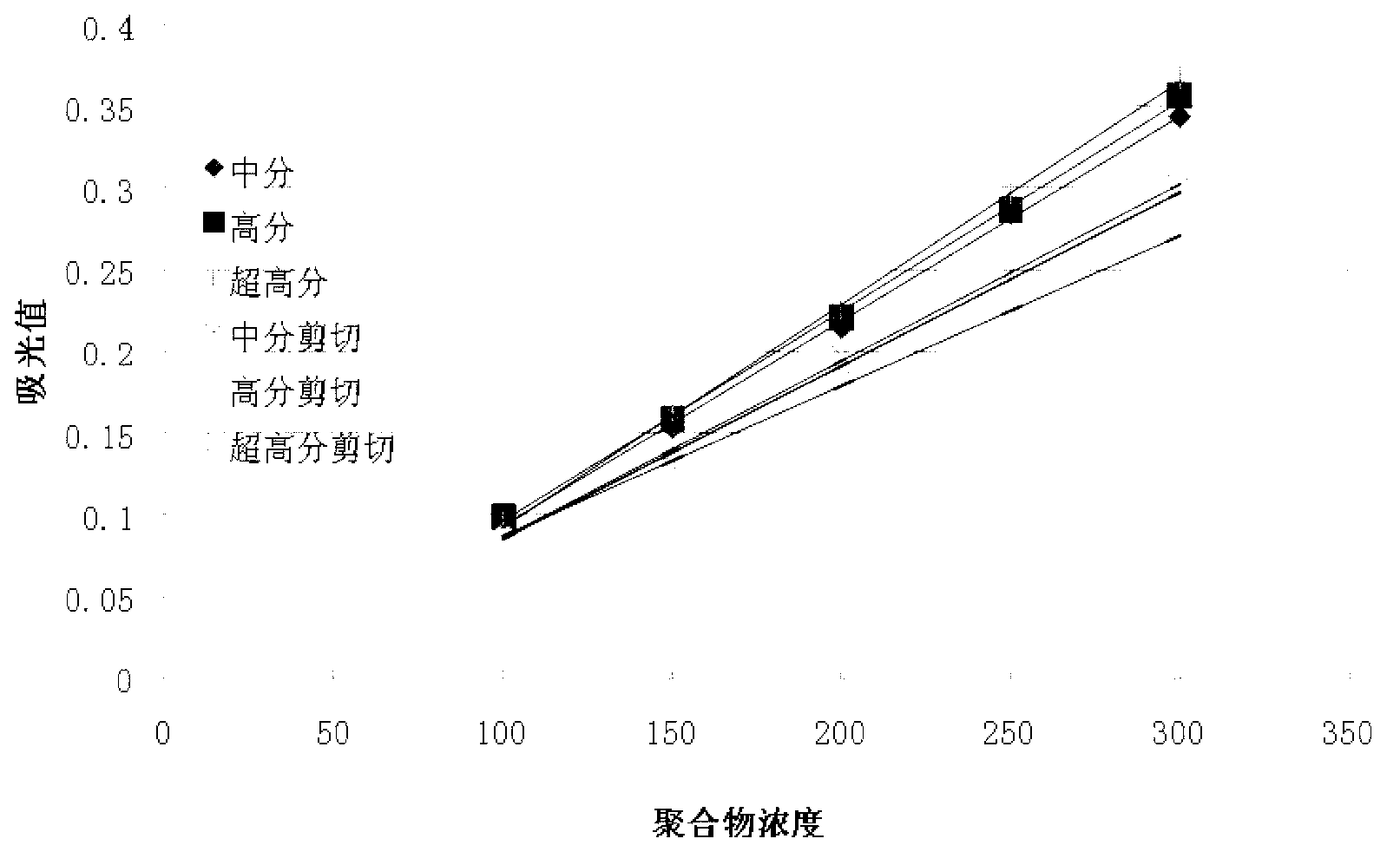

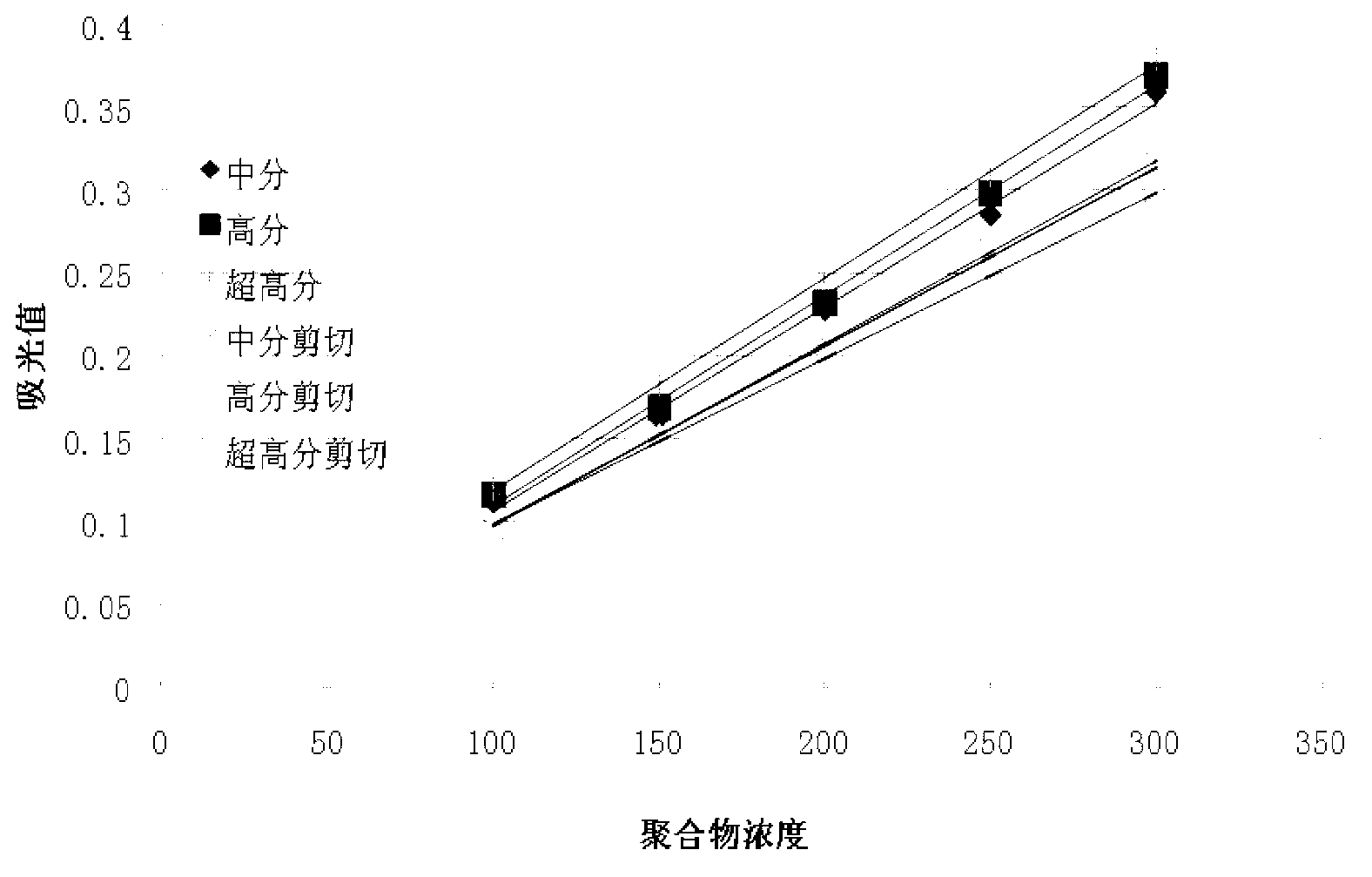

[0024] Embodiment 1 nephelometry detects polymer concentration

[0025] Select three molecular weight polymers of medium, high and ultra-high fractions (the specific molecular weight polymer selected when drawing the standard curve is the same or substantially close to the molecular weight of the polymer injected in this area), and prepare 100mg / L, 150mg / L, 200mg / L, 250mg / L, 300mg / L polyacrylamide standard solution. Standard solutions of each concentration were divided into two groups, A and B. Group A was not subjected to shearing treatment; group B used a high-speed shearing machine to shear polymer standard solutions of different concentrations for 30 seconds at a speed of 11,000 rpm.

[0026] The absorbance value of each concentration standard solution was measured by turbidity method, the concentration standard curve was made respectively, and the detection error of polymer concentration before and after shearing was observed. Refer to Table 1, Table 2, and Table 3 for ...

Embodiment 2

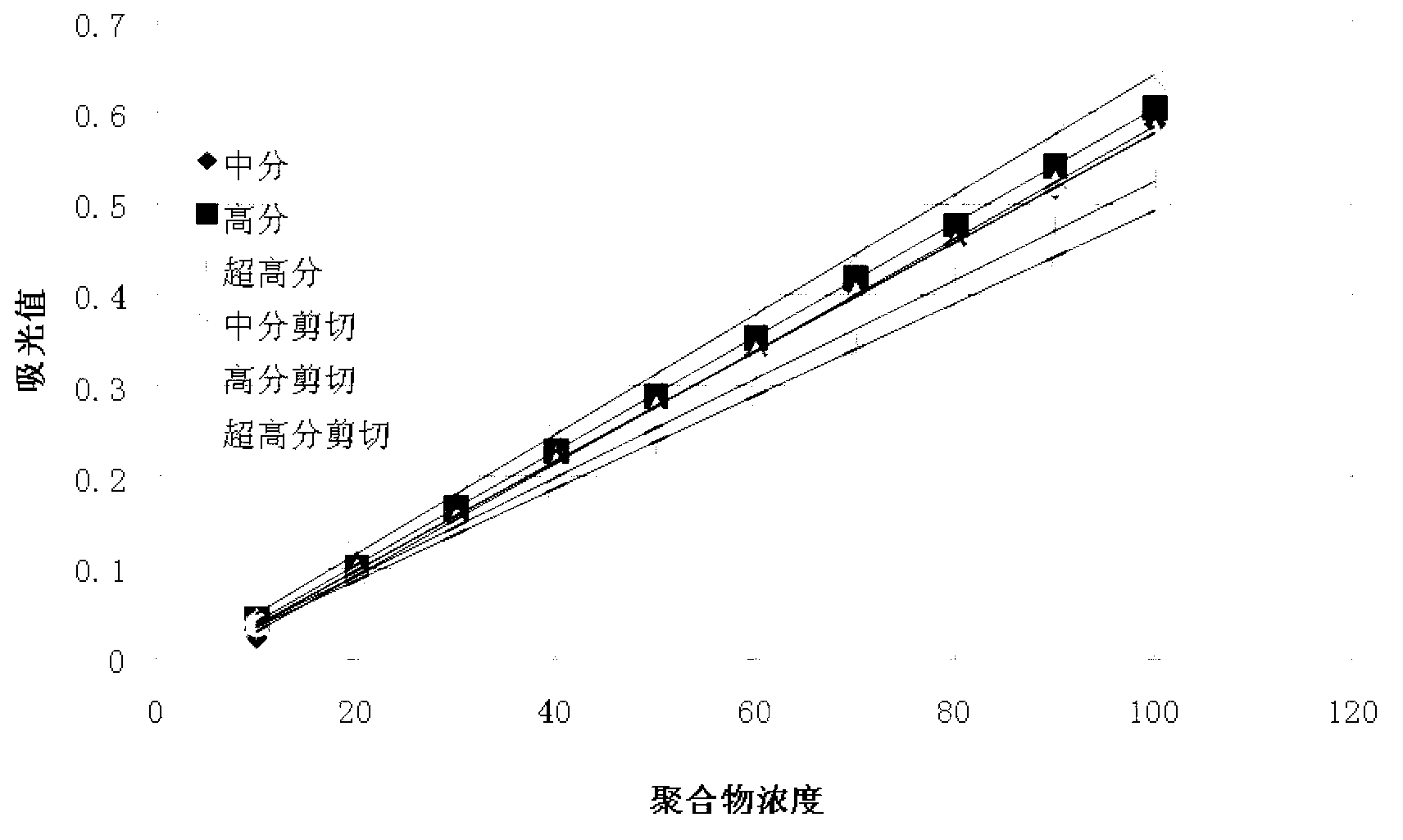

[0037] Embodiment 2 starch-cadmium iodide method detects polymer concentration

[0038] Select three molecular weight polymers of medium fraction, high fraction and ultra-high fraction, and prepare 10mg / L, 20mg / L, 30mg / L, 40mg / L, 50mg / L, 60mg / L, 70mg / L, 80mg / L, 90mg / L, 100mg / L polyacrylamide standard solution. Standard solutions of each concentration were divided into two groups, A and B. Group A was not subjected to shearing treatment; group B used a high-speed shearing machine to shear polymer standard solutions of different concentrations for 30 seconds at a speed of 11,000 rpm.

[0039] The absorbance value of each concentration standard solution was determined by the starch-cadmium iodide method, and the concentration standard curve was prepared respectively, and the detection error of the polymer concentration before and after shearing was observed. Refer to Table 5, Table 6, and Table 7 for the determination results of medium score, high score and super high score. F...

Embodiment 3

[0050] Embodiment 3 Changes the influence of shear time and shear velocity on polymer solution

[0051] 1) Cutting time

[0052] Use medium fraction polymer, high fraction polymer and super high fraction polymer respectively to prepare 200mg / L solution, use high-speed shearing machine at 11000 r / min, shear for different times, and detect the polymer viscosity after shearing and molecular weight changes.

[0053] Table 9 Shear time influence on polymer

[0054]

[0055] From the experimental results, the shearing time has little effect on the polymer viscosity, and the molecular weight of the polymer does not change much after shearing for 30s, which is closest to the molecular weight of the polymer in the production fluid (after testing, the molecular weight of the polymer in the actual production fluid is about 300-400 million), therefore, the present invention selects the cutting time to be at least 30s.

[0056] 2) Shear speed

[0057] Use medium-fraction polymer, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com