Integrated circuit shielding film and manufacturing method thereof

A technology of shielding film and film layer, which is applied in the fields of magnetic field/electric field shielding, coating, metal material coating process, etc., can solve the problem of IC easy to fall off, and achieve the effect of avoiding expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to understand the technical features, content and advantages of the present invention and the effects that can be achieved, the present invention is now combined with the accompanying drawings, and is described in detail in the form of embodiments as follows, and the drawings used therein are only intended to The purpose of illustration and auxiliary instructions is not necessarily the true proportion and precise configuration of the present invention after implementation, so the scale and configuration relationship of the attached drawings should not be interpreted or limited to the scope of rights of the present invention in actual implementation. bright.

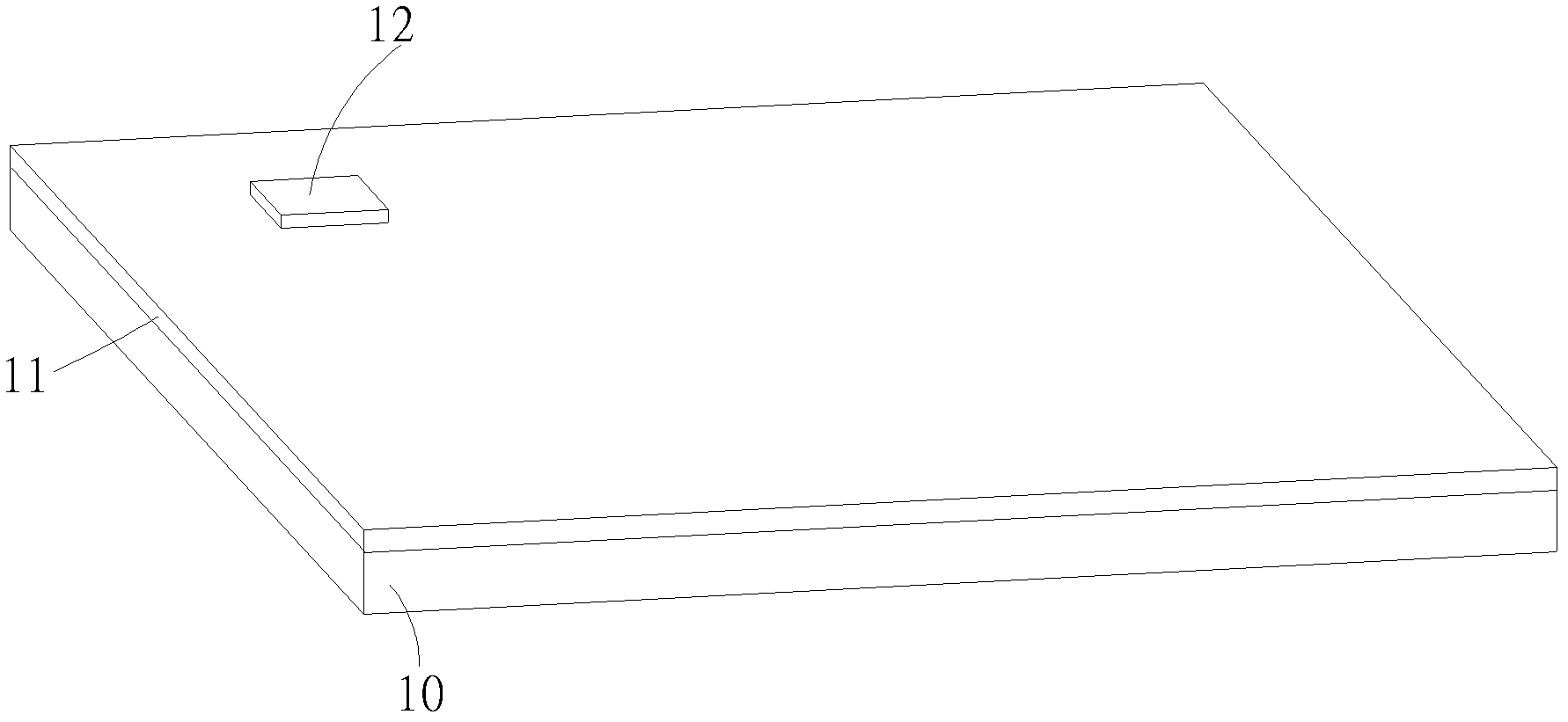

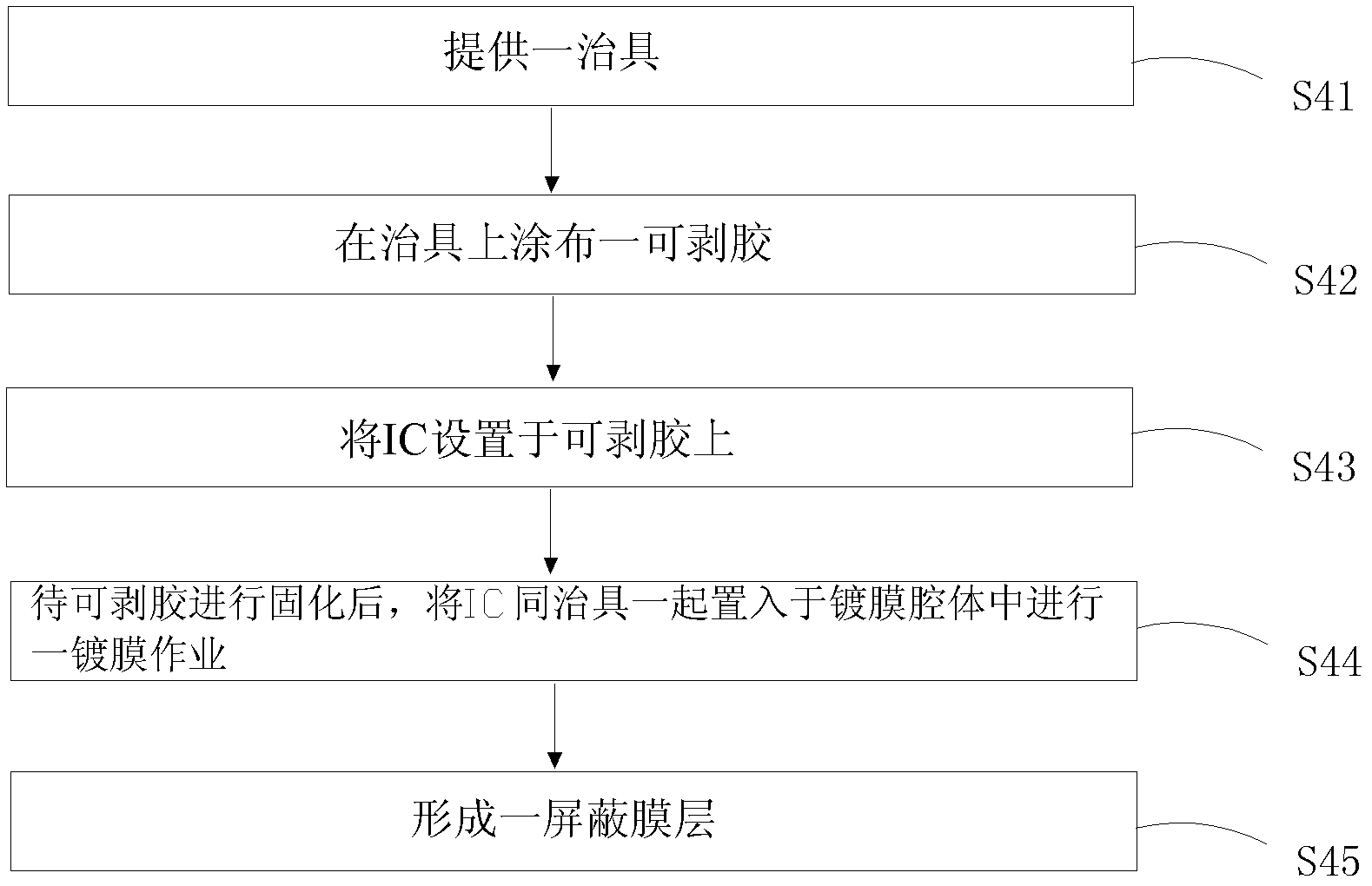

[0042] see figure 1 , which is a schematic diagram of the first embodiment of the manufacturing method of the IC shielding film layer of the present invention. The manufacturing method of the IC shielding film in this embodiment is mainly to provide a jig 10 first, and the jig 10 can be made of aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap