An apparatus and a method for introducing a first fluid into the flow path of a second fluid and use of such an apparatus

A first fluid and fluid technology, applied in the direction of chemical instruments and methods, flow control, fluid mixer, etc., can solve the problems of insufficient steam mixing, difficult mixing or diffusion blending fluid, implosion, etc., to reduce steam The effect of implosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The embodiments of the invention described below are intended for use in process installations where a first fluid in the form of steam is mixed into the flow path of a second fluid in the form of a cellulose pulp suspension, wherein hot steam is used to heat the pulp suspension to Desired temperature, eg a temperature suitable for the subsequent bleaching step. However, it should be understood that the principles of the present invention can be used to mix other fluids into the pulp suspension, for example gases such as oxygen, chlorine or ozone or liquids such as pH adjusting fluids, chlorine dioxide or other treatment fluids. class of liquids. It should also be understood that the second fluid may be of another type than a pulp suspension, eg a process solution.

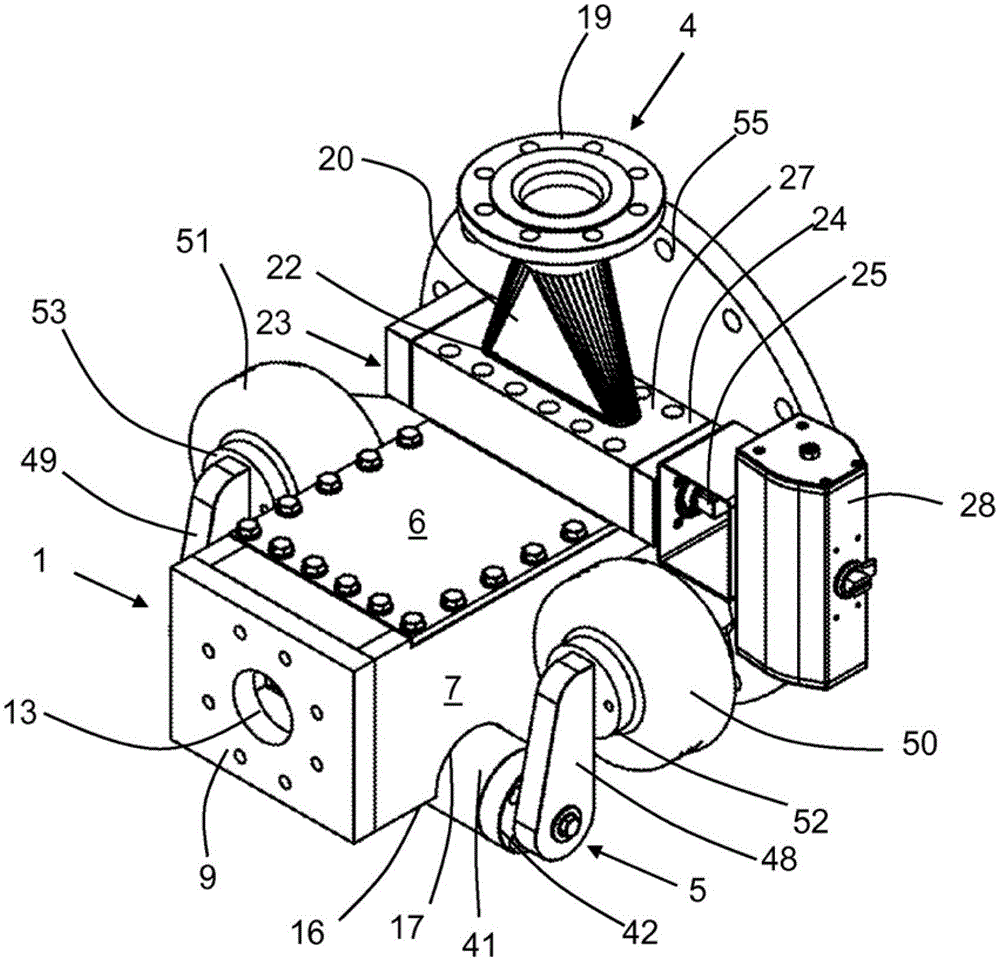

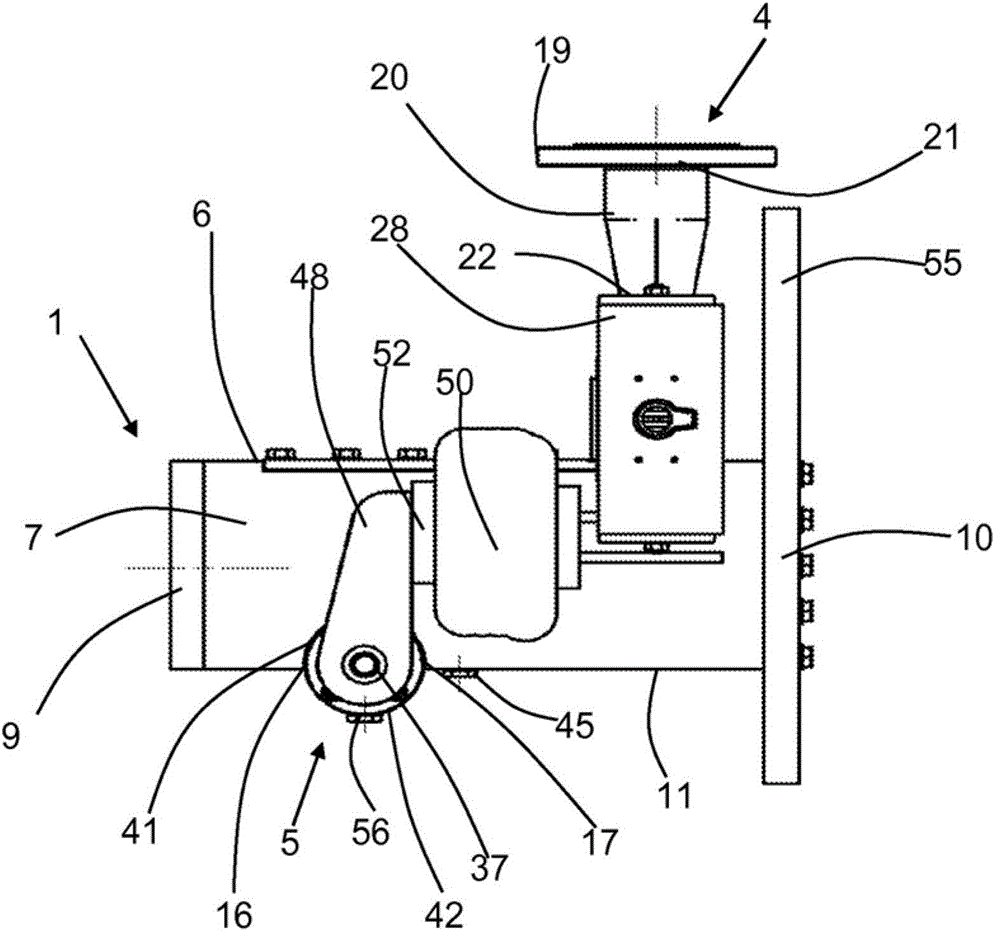

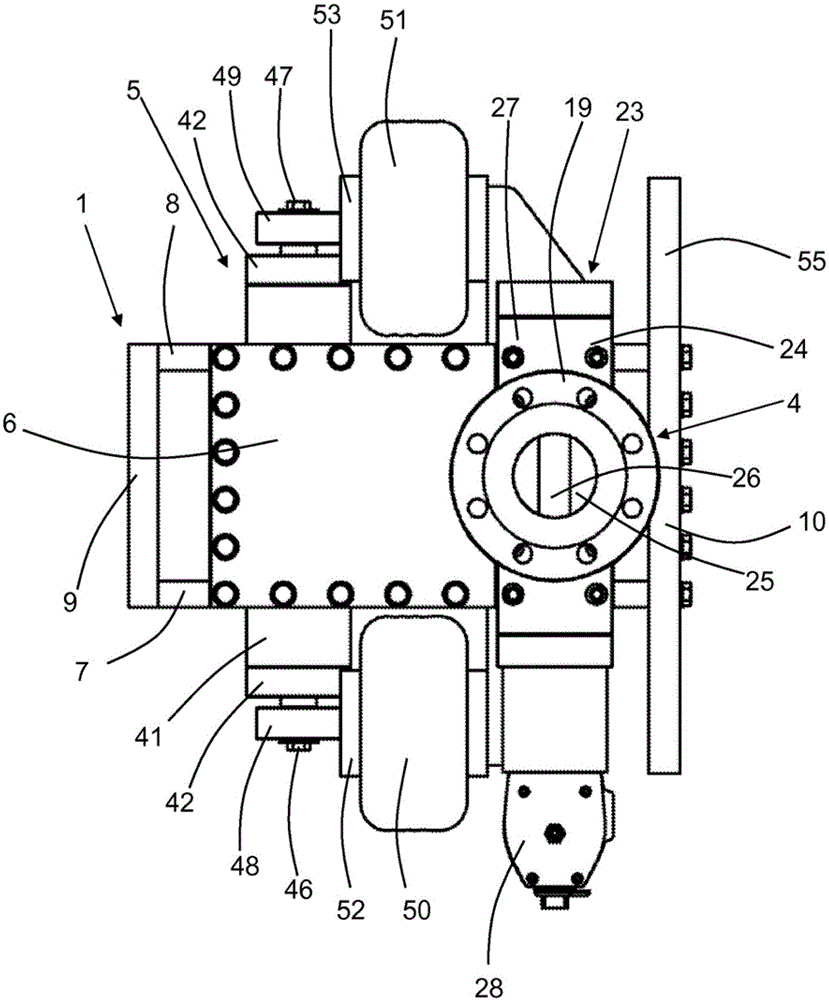

[0041] The device comprises a substantially parallelepiped housing 1 for receiving pulp suspension from a first conduit 2 upstream and for discharging the pulp suspension into a second conduit 3 downstream....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com