Eccentric rocking type reduction gear

A reduction gear and eccentric technology, which is applied in the direction of gear transmission, belt/chain/gear, transmission device, etc., can solve the problems of shortened bearing life and vibration of eccentric oscillating reduction gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

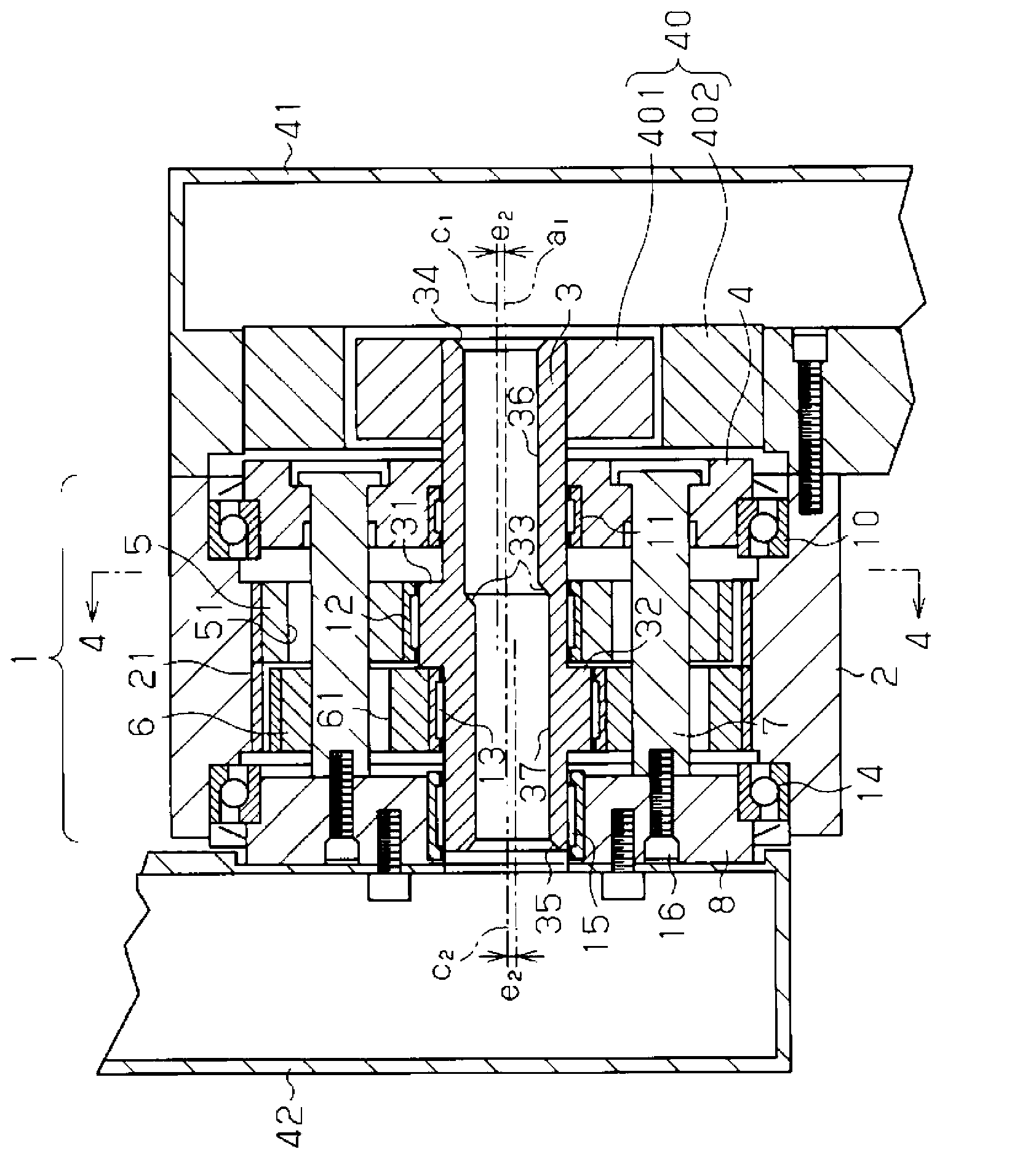

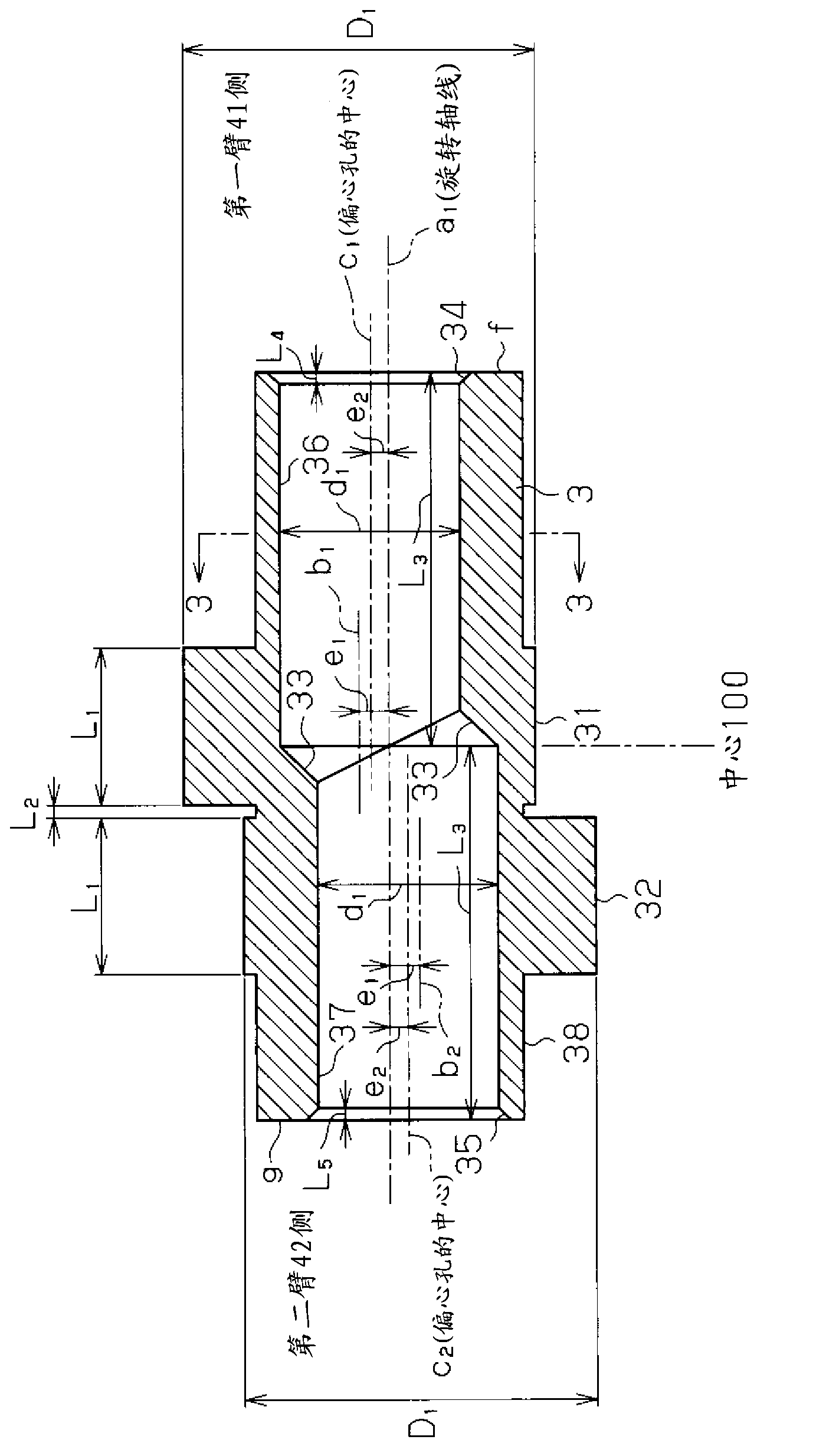

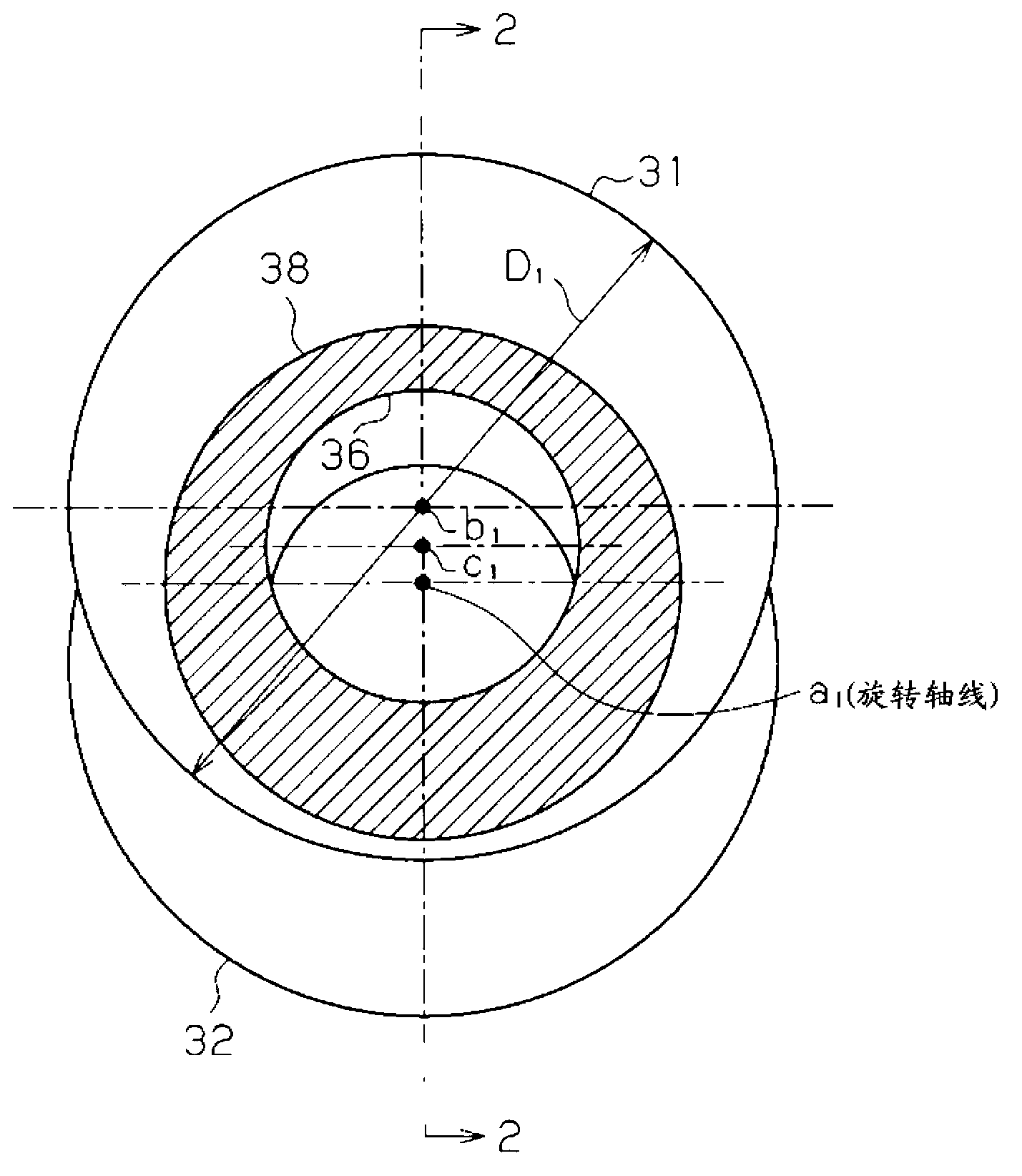

Method used

Image

Examples

Embodiment approach

[0115] The present invention can be modified as follows.

[0116] In this embodiment, by increasing or decreasing the depth L of the chamfers 34 and 35 4 and L 5 , the unbalance amount of the crankshaft 3 can be finely adjusted, but the following modifications can also be applied. For example, as Figure 10 As shown in (a), additional holes 87 may be formed in at least either end of the crankshaft 3, or, as in Figure 10 As shown in (b), a counterweight 88 can be added. Furthermore, by using the hole 87 and the counterweight 88 at the same time, the balance of the crankshaft 3 can be adjusted. Furthermore, by partially cutting the circumferential surface of the crankshaft 3, that is, cutting the cylindrical portion 38, rather than cutting the end of the crankshaft 3, the balance can be adjusted. In this case, the hole 87 and the balance weight 88 serve as the axial end balance adjustment portion.

[0117] When the hole 87 is used to adjust the balance of the couple actin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com