Glow plug and method for the production thereof

A preheating plug and preheating tube technology, applied in combustion methods, lighting and heating equipment, combustion ignition, etc., can solve the problems of using, elastic body can no longer be used as sealing elements, etc., and achieve high heat resistance and reliable cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

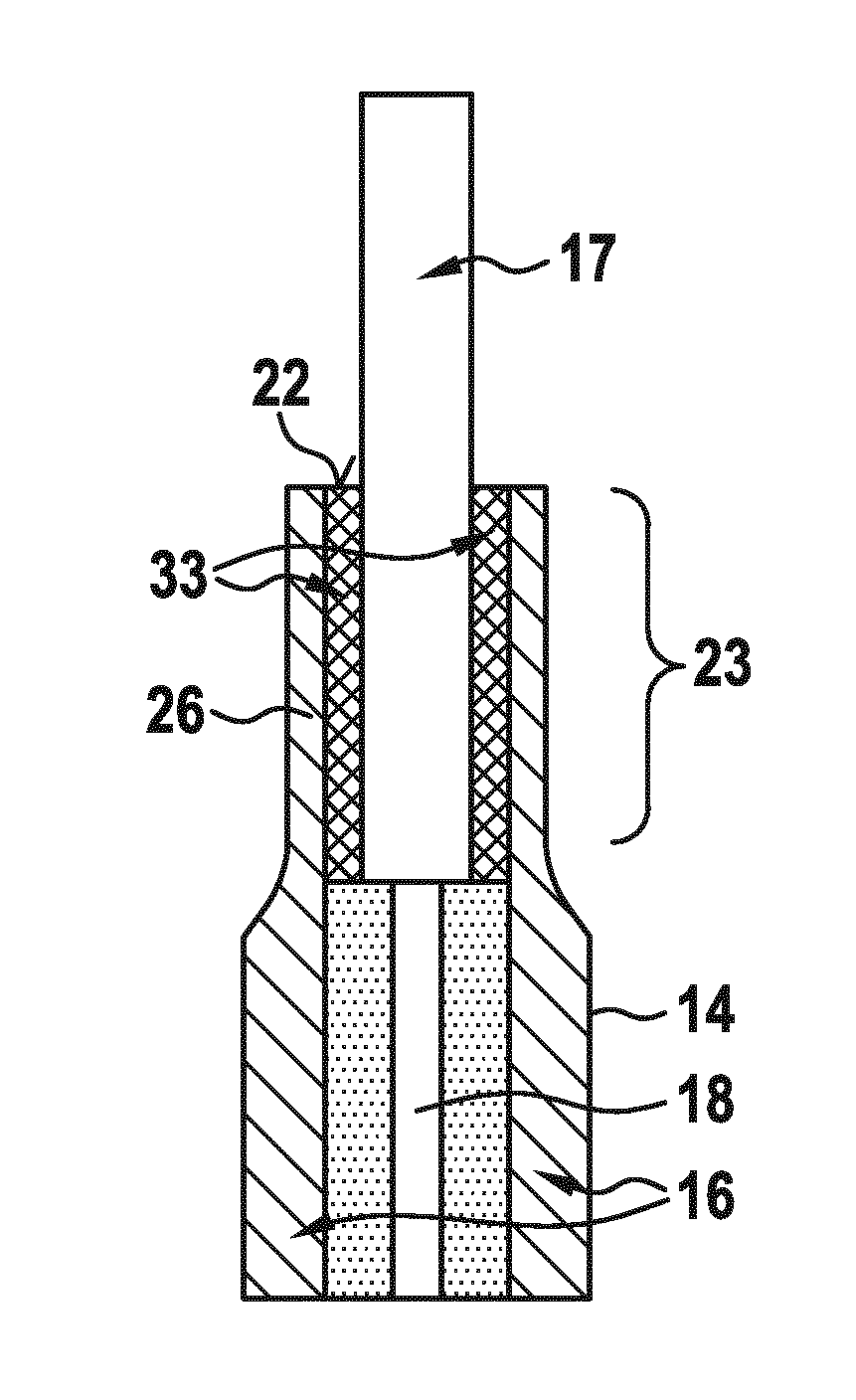

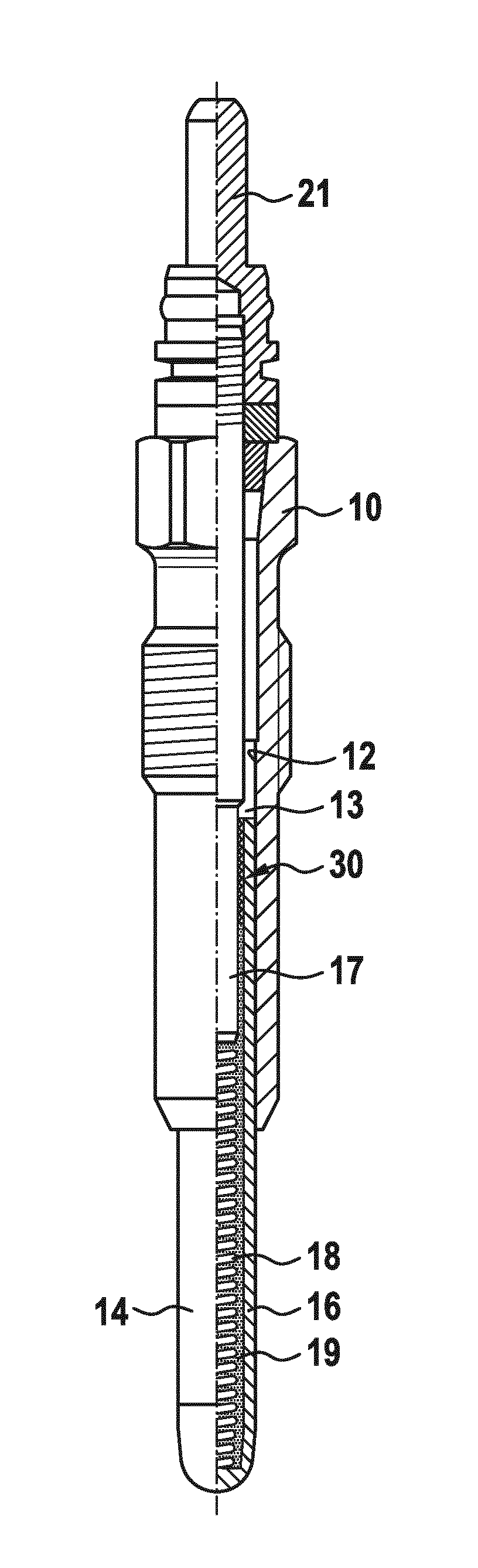

[0011] The glow plug shown in FIG. 1 has a metal housing 10 with a through longitudinal hole 12 into which a glow rod 14 is pressed as a heating body. The glow rod 14 consists of a metallic glow tube 16 in which is arranged a glow plug coil 18 which is in electrical contact with the glow tube 16 at one end and which at the other end is in electrical contact. One end is in electrical contact with the connecting bolt 17 . The connecting bolts 17 leading out of the housing 10 at the end opposite the preheating rod 14 and having the connection 21 are enclosed within the housing 10 by an annular space 13 which is in turn closed to the external environment. of.

[0012] The preheating tube 16 is closed at the end pointing into the combustion chamber of the internal combustion engine and has an opening 22 at the opposite end facing the annular space 13 .

[0013] For the service life of glow plug coil 18 it is important to protect the material of glow plug coil 18 from oxidizing or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com