Solid-liquid separation all-in-one machine for extracting juice of flowers and grasses

A solid-liquid separation and integrated machine technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of long transportation time of raw materials, heavy equipment, large loss, etc., and achieve the elimination of drum dredging mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

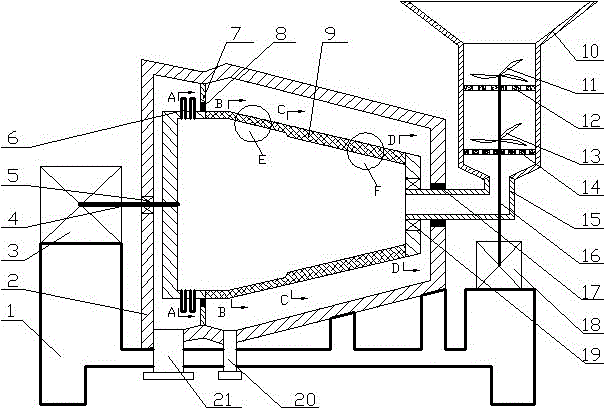

[0018] Based on the above purpose, the present invention mainly includes: support 1, housing 2, drum motor 3, drum shaft 4, sealed bearing 5, discharge pipe 6, sealing baffle 7, sealing ring 8, drum 9, minced Housing 10, coarse reamer 11, coarse screen 12, fine reamer 13, fine screen 14, feeding pipe 15, reamer shaft 16, sealed sliding bearing 17, reamer motor 18, sealed rolling bearing 19, liquid outlet Pipe 20, solid matter discharge pipe 21; wherein drum 9 includes drum shell 9-1, high-frequency elastic material 9-2, elastic material fixed net 9-3, vibrating ball fixed net 9-4, vibrating ball 9-5 , filter screen 9-6.

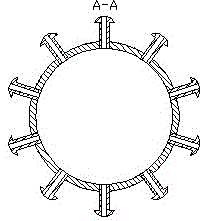

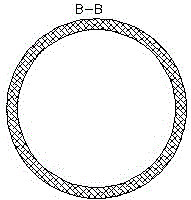

[0019] The specific spatial structure such as figure 1 — Figure 8 Shown: figure 1 for the overall structure, figure 2 It is the A-A sectional view of the outlet pipe 6, image 3 It is a sectional view of B—B on the drum 9, Figure 4 It is a C-C sectional view on the drum 9, Figure 5 D—D cross-sectional view for drum 9, Image 6 It is an enlarged v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com