Rapid punching device for flexible material

A flexible material and punching device technology, which is applied in metal processing and other directions, can solve the problems of untargeted fast punching devices for flexible materials, and achieve the effect of avoiding material adhesion and high punching reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

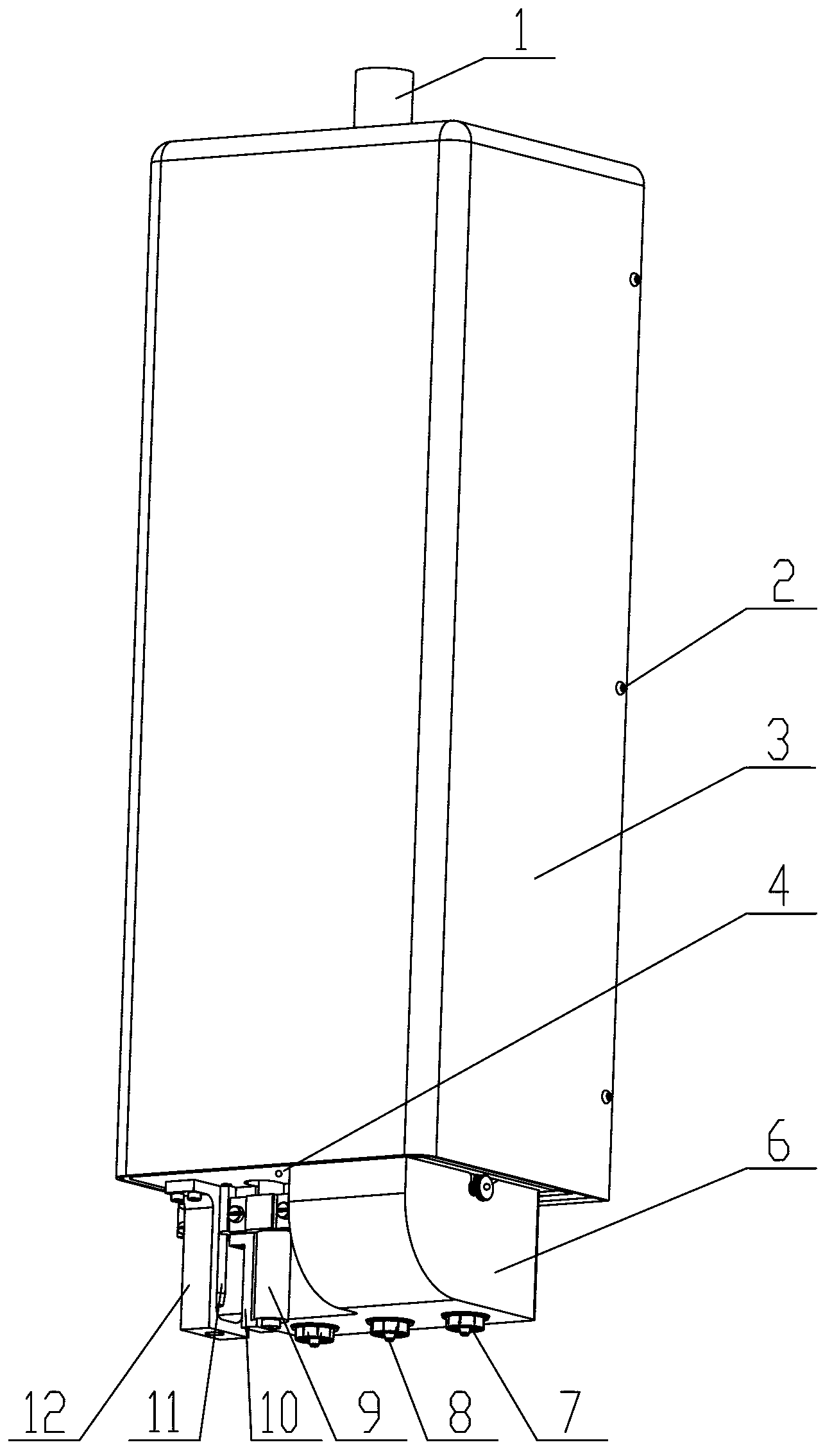

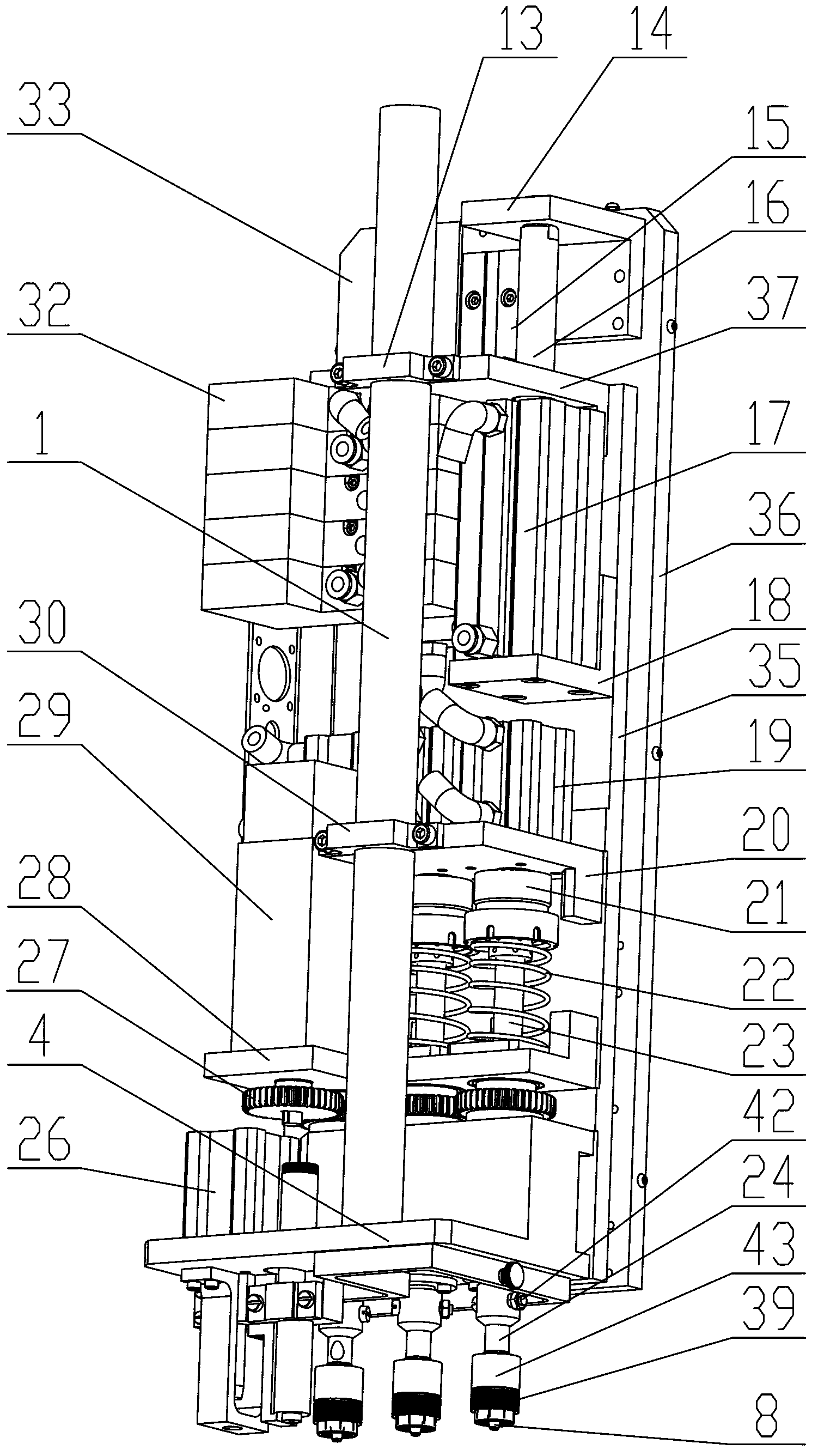

[0009] Specific implementation mode one: combine Figure 1 to Figure 3 Explain, the flexible material rapid punching device of this embodiment, the flexible material rapid punching device includes a front bottom plate 35, a rotary punching knife mechanism and a solenoid valve group 32; the rotary punching knife mechanism includes a cylinder support frame 20. Motor base 28, gear set 27, motor 29, at least one small air cylinder 19 for punching, at least one tool bar connecting sleeve 21, at least one tool bar shaft 23, at least one spring 22 and at least one punching tool head assembly 39 The quantity of small cylinder 19, knife rod connecting sleeve 21, knife rod shaft 23, spring 22 and punching cutter head assembly 39 for punching is all the same, and small cylinder 19 for punching is affixed with front base plate 35 by cylinder support frame 20 , the cylinder rod of the small cylinder 19 for punching is set downwards and fixedly connected with the knife bar connecting sleeve...

specific Embodiment approach 2

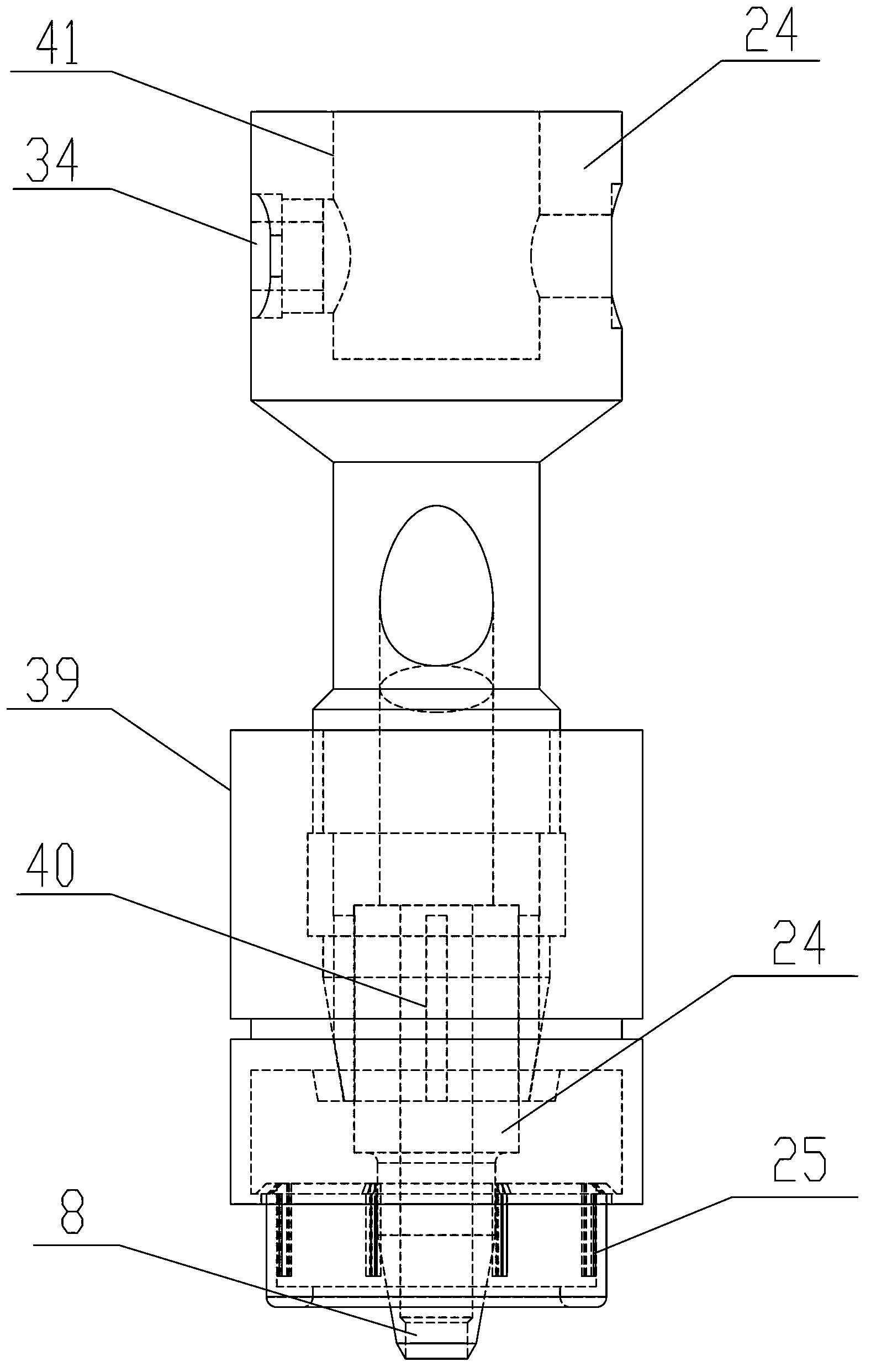

[0010] Specific implementation mode two: combination Figure 1 to Figure 3 Illustrate, the punching cutter head assembly 39 described in the present embodiment comprises punching cutter rod 24, punching cutter rod thread sleeve 34, collet sleeve 25 and punching cutter head 8; The center of the end face is provided with a blind hole 41 axially, the lower end of the tool bar shaft 23 is arranged in the blind hole 41 of the punching knife bar 24, and the side wall corresponding to the punching knife bar 24 and the blind hole 41 is provided with The radial mounting hole, the punching knife bar threaded sleeve 34 is fixed in the radial mounting hole, the punching knife knife bar 24 is fixedly connected with the knife bar shaft 23 by the set screw 42 screwed into the punching knife bar threaded sleeve 34, The punching knife bar 24 and the punching knife cutter head 8 are fixed by the collet cover 25, so that it is convenient to change the punch. The undisclosed technical features i...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 and image 3 It is explained that the punching head assembly 39 in this embodiment also includes a punching knife holding ring 7; It is used to reduce the local deformation in the working area of the material during punching. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com