Four-axis single-hinge hinge type passenger car structure

A articulated, single-hinge technology, applied in the direction of motor vehicles, transportation, and packaging, can solve the problems of multiple road spaces, large turning channel width, and occupancy, and achieve the goal of reducing floor space, saving road resources, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

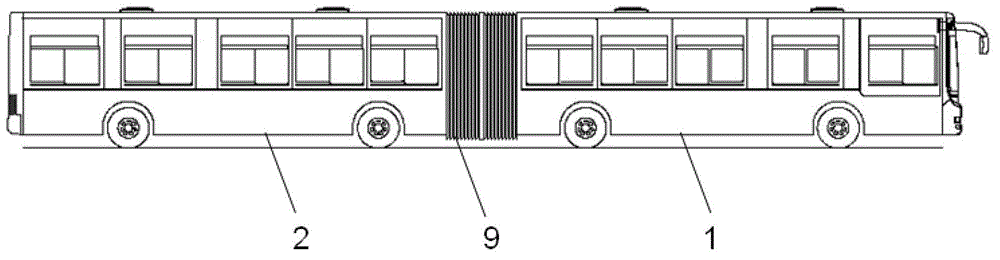

[0021] The main size parameters used in this program are attached Image 6 As shown, where: C is the length of the front overhang, L is the wheelbase between the front axle of the main vehicle and the rear axle, D is the distance from the rear axle of the main vehicle and the front axle of the auxiliary vehicle to the center of the hinge, and E is the front axle of the auxiliary vehicle and the wheelbase between the rear axle, K is the width of the vehicle.

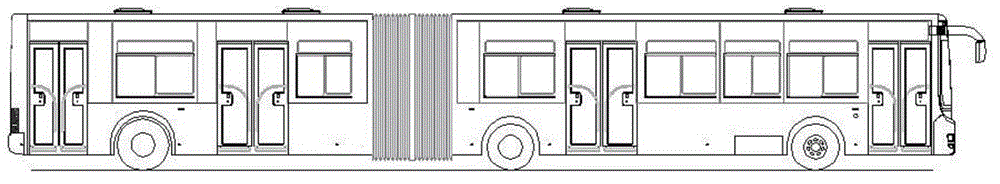

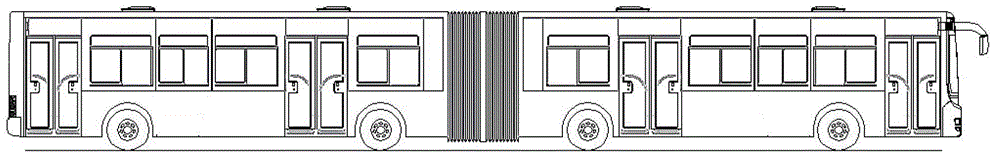

[0022] The vehicle structure is composed of two parts, the main vehicle 1 and the auxiliary vehicle 2, and the two parts are connected to each other through the traction hinge plate 8 and the soft roof 9. Both the main vehicle 1 and the auxiliary vehicle 2 are double-axle structures, and the whole vehicle is a 4-axle structure. The front axle 3 of the main vehicle is a steering axle, the rear axle 4 is a drive axle, the front axle 5 of the auxiliary vehicle is a follower axle, and the rear axle 6 is a linkage steering br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com