High-speed ship of absorbing water at front part and spraying water at back part

A high-speed, hole-absorbing technology, applied in the direction of ship hull, ship propulsion, ship parts, etc., to achieve the effect of large traction and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

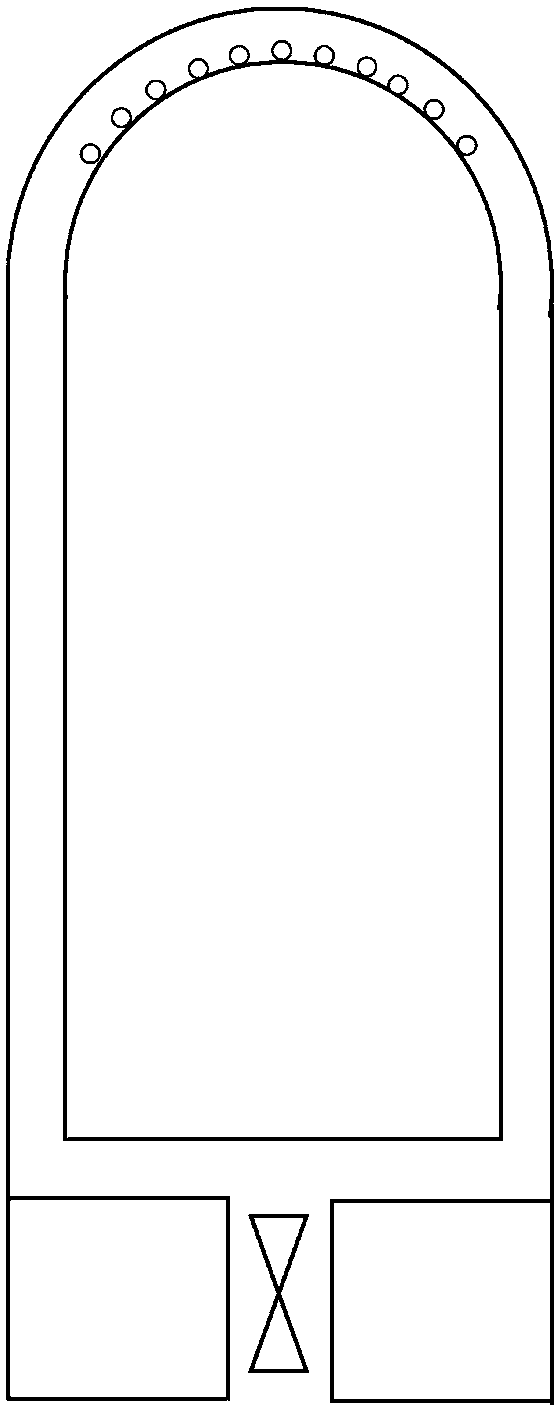

[0009] figure 1 It is a schematic diagram of a high-speed ship with water spraying after absorbing water before. The cabin is a cuboid; the bow is a fluid shape, semi-cylindrical or lower semi-cylindrical, with a quarter-spherical upper part; water pipes surround the hull, the front end opens holes to absorb water, and the rear end high-pressure water pump sprays water. Its remarkable advantage is that the front end opens upwards. The hole absorbs water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap