Automatic cup filling device suitable for sticky food

A transmission device and cup filling technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of insufficient production efficiency and achieve the effects of improved efficiency, simple operation, and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

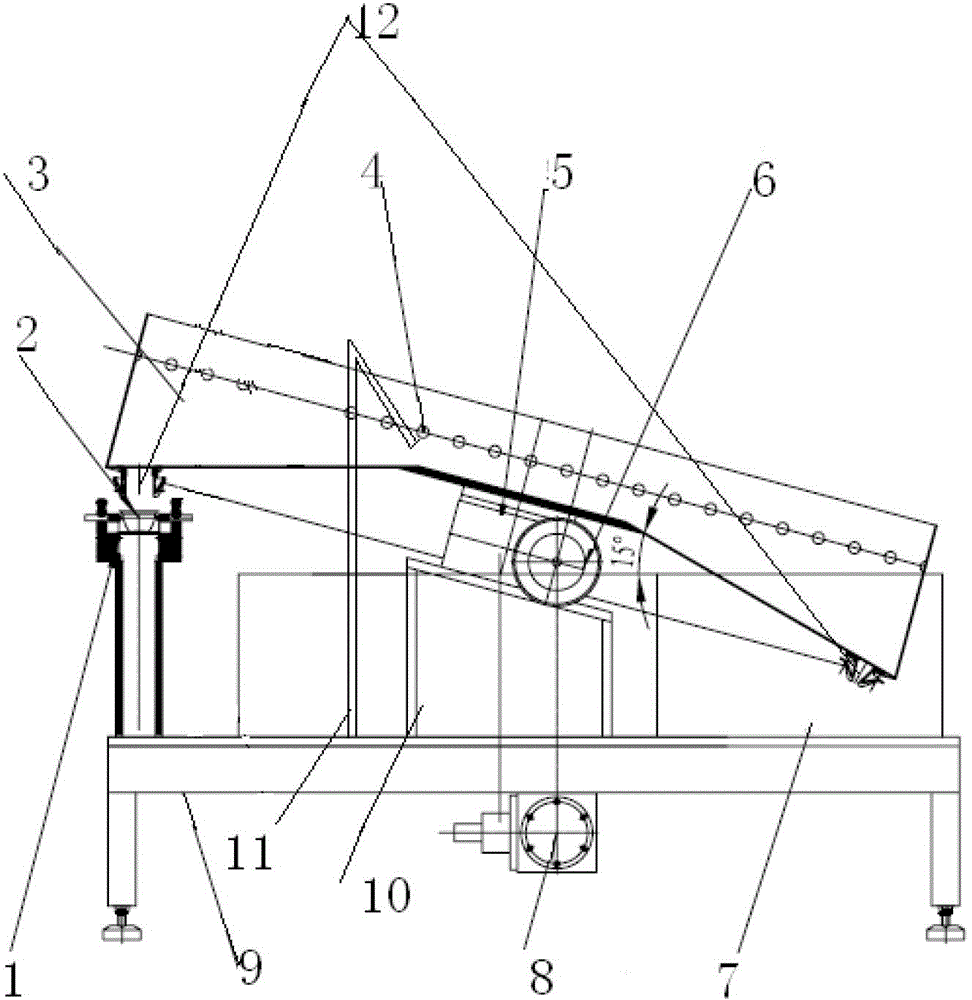

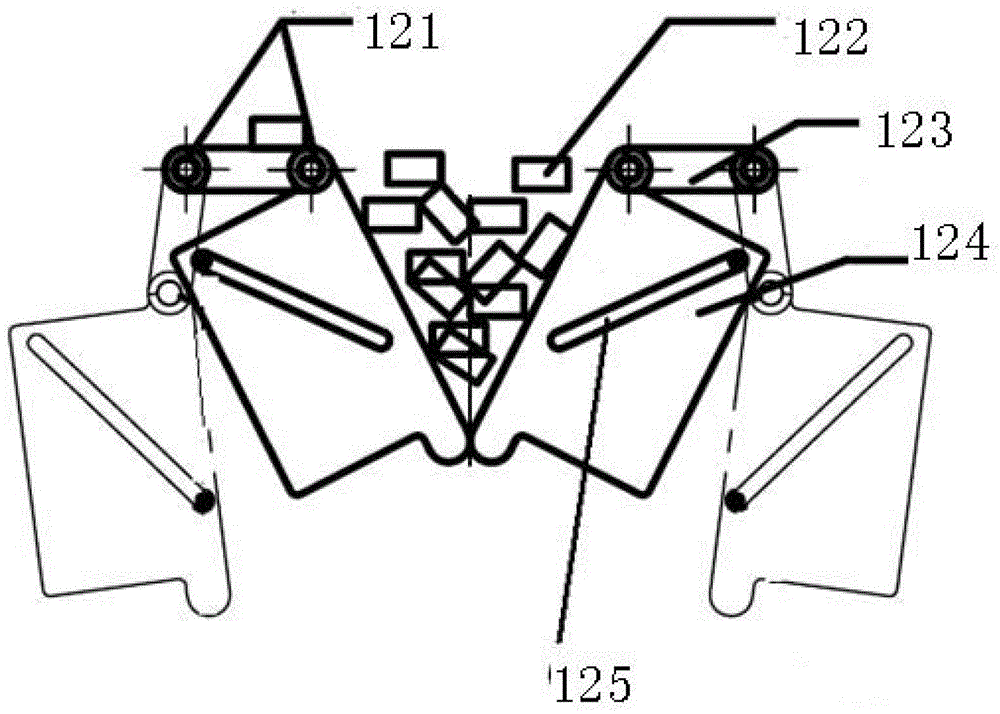

[0016] An automatic cup filling device suitable for wet and sticky food, such as figure 2 As shown, an automatic cup filling device suitable for wet and sticky food includes a frame 9, a transmission device, a rotating barrel 3 with two metering devices 12 at both ends, and the rotating barrel 3 forms a certain angle with the horizontal plane ( The included angle is 15°) is connected with the transmission device, and the transmission device is connected and fixed on the frame 9 .

[0017] Further, the transmission device includes a power input gearbox 8 , a gear 6 , and a worm gear box 5 , the worm gear box 5 is connected to the gear 6 , and the gear 6 is connected to the power input gearbox 8 .

[0018] Further, an overflow port 4 is also provided around the rotating barrel 3 .

[0019] Further, a conveyor belt 1 is installed on the end of the frame 9 clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com