Method for removing arsenium from water body by macroporous resin adsorption process

A technology of macroporous resin and adsorption method, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Resin adsorption capacity and other issues, to achieve the effect of low cost, no secondary pollution, and low residual arsenic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The experimental raw material: an arsenate solution prepared with local tap water, with an initial total arsenic content of 1500.0 μg / L.

[0042] Loading pretreatment conditions: D401 macroporous resin was selected and treated with different concentrations of ethanol, hydrochloric acid and NaOH. Other pretreatment conditions are the same.

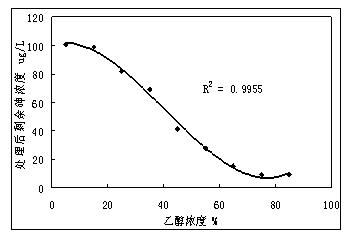

[0043] The influence of different pretreatment conditions on the final adsorption effect is shown in image 3 , 4 with Figure 5 .

[0044] Depend on image 3 , 4 , 5. It can be seen that different pretreatment agent concentrations have a regular influence on the final arsenic removal effect. Considering the combination of cost reduction, industrial promotion factors and influence, the pretreatment agent concentration is finally determined to be 10-90% ethanol , 0.095-0.95mol / L hydrochloric acid and 0.1-1.0mol / L NaOH, and after combining the optimal conditions, the concentration of residual arsenic can be reduced to below 10μg...

Embodiment 2

[0046] The pretreated D401 macroporous resin is loaded with a 0.02-0.29 mol / L solution containing a zirconium compound, and after loading, the preparation solution with an initial pentavalent arsenic concentration of 950.0 μg / L is treated.

[0047] When other conditions such as adsorption time and temperature are the same, the effect of different concentrations of zirconium solutions on the loading effect is shown in Image 6 (Evaluation is based on the adsorption effect on arsenic under the same conditions).

[0048] Image 6 It shows that the solution concentration of different zirconium-containing compounds has an impact on the loading effect, and will eventually affect the arsenic removal effect. After sufficient time and adsorption under optimal conditions, the concentration of remaining arsenic can be reduced to below 10 μg / L.

Embodiment 3

[0050] The loaded macroporous resin is dried in a drying oven at 5-35°C for a drying time of 0-20 hours, and then the pentavalent arsenic solution is adsorbed (the initial total arsenic concentration is 985.0 μg / L).

[0051] Under the same conditions of arsenic solution adsorption time, solution temperature, solution pH, stirring intensity and other influencing factors, see Figure 7 , 8 .

[0052] Figure 7 with Figure 8 It can be seen that different drying temperatures and drying times have an impact on the loading effect, which in turn will affect the arsenic removal capacity and effect of the resin, but after treatment under the optimal drying temperature and drying time conditions, the concentration of residual arsenic after adsorption Very low, has reached drinking water standards.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap