Rotary drilling rig and control method, device and system thereof

A technology of a rotary drilling rig and a control method, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of affecting the service life of the main winch and the decrease of the service life of the main winch, and achieve the purpose of improving the performance and Safety, solution to life reduction, impact prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0027] The embodiment of the present invention considers that although the way of quickly shaking the drill pipe can shake off the soil in the drill pipe, if the shaking frequency is too fast, the impact force on the main winch will be relatively large, which will affect its life. Based on this, embodiments of the present invention provide a rotary drilling rig and a control method, device and system thereof, which will be described below through embodiments.

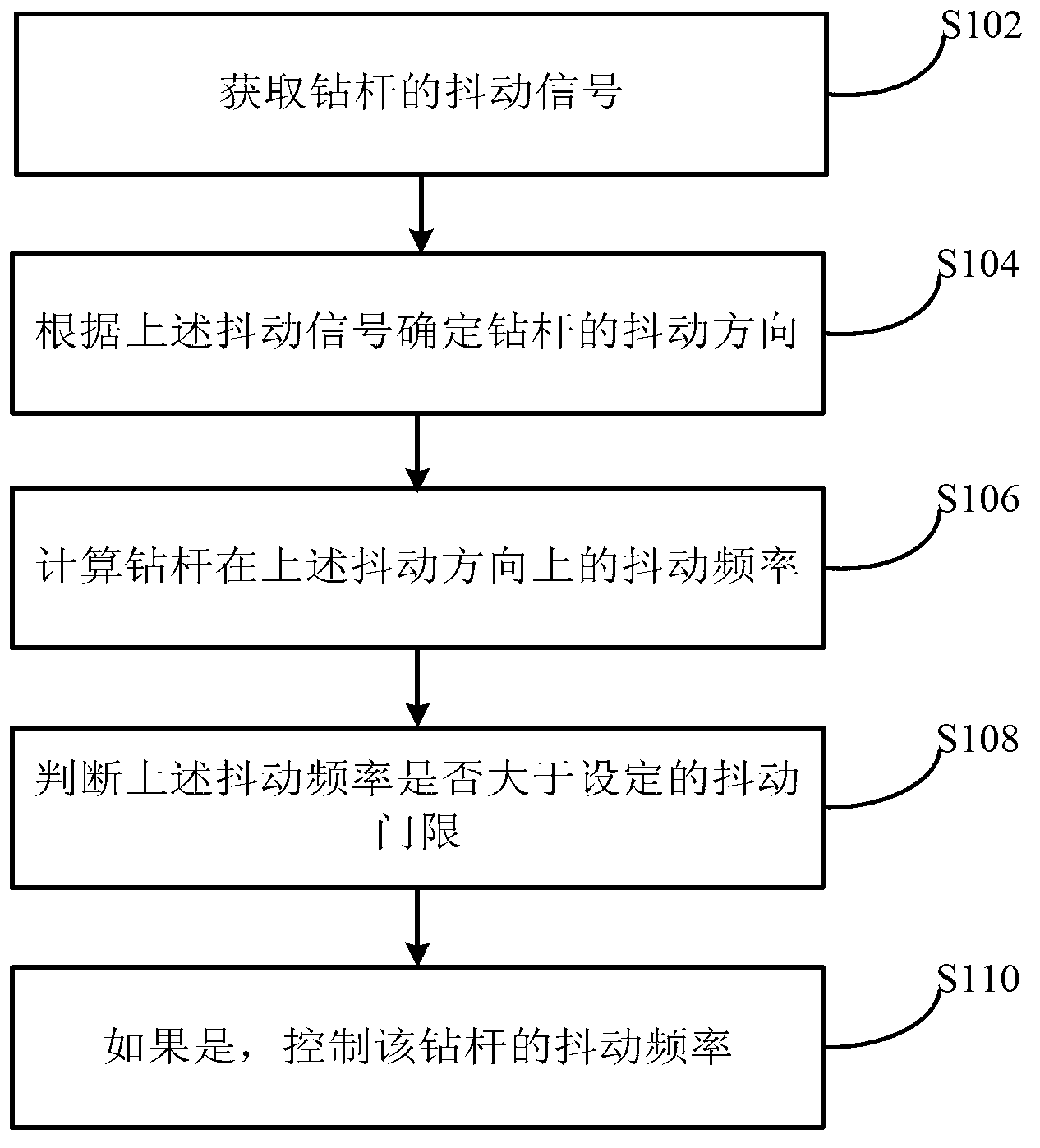

[0028] see figure 1 The flow chart of the control method of the rotary drilling rig shown, the method can be applied on the controller (PLC) of the rotary drilling rig, and it includes the following steps:

[0029] Step S102, obtaining the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com