Fully-mechanized excavating machine

A fully mechanized excavator and machine body technology, applied in the field of fully mechanized excavation equipment, can solve the problems of increased energy, poor dust reduction effect, and affecting machine performance, so as to ensure the effect of atomization, reduce the amount of production, and ensure the effect of the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

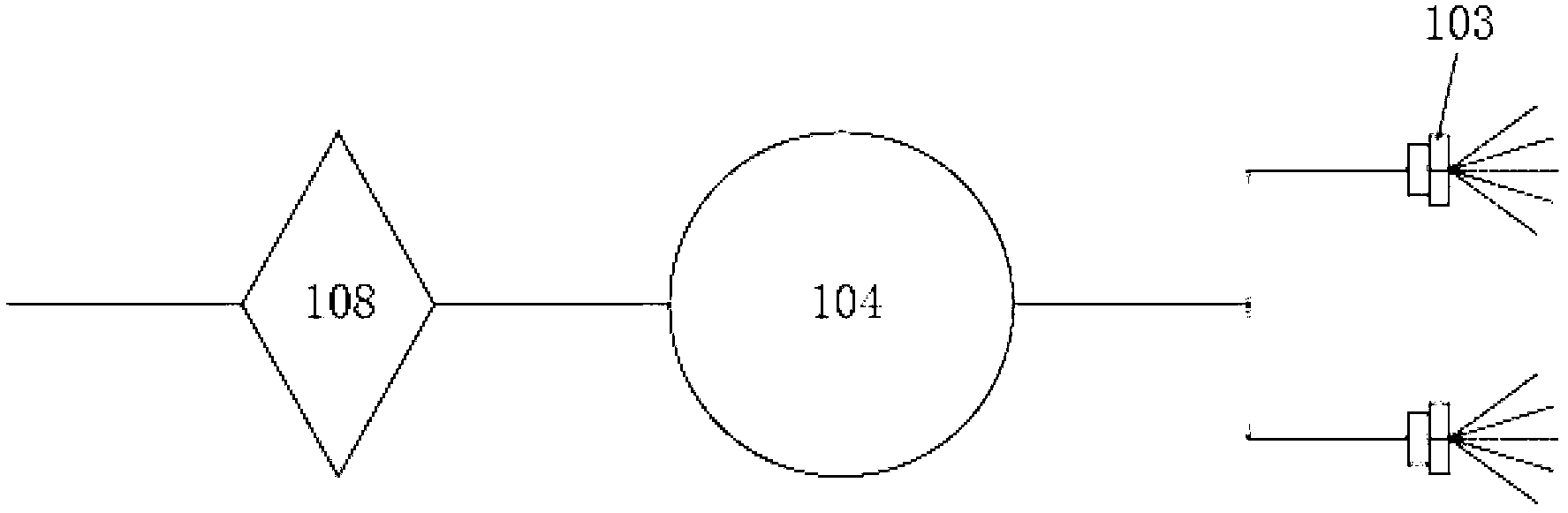

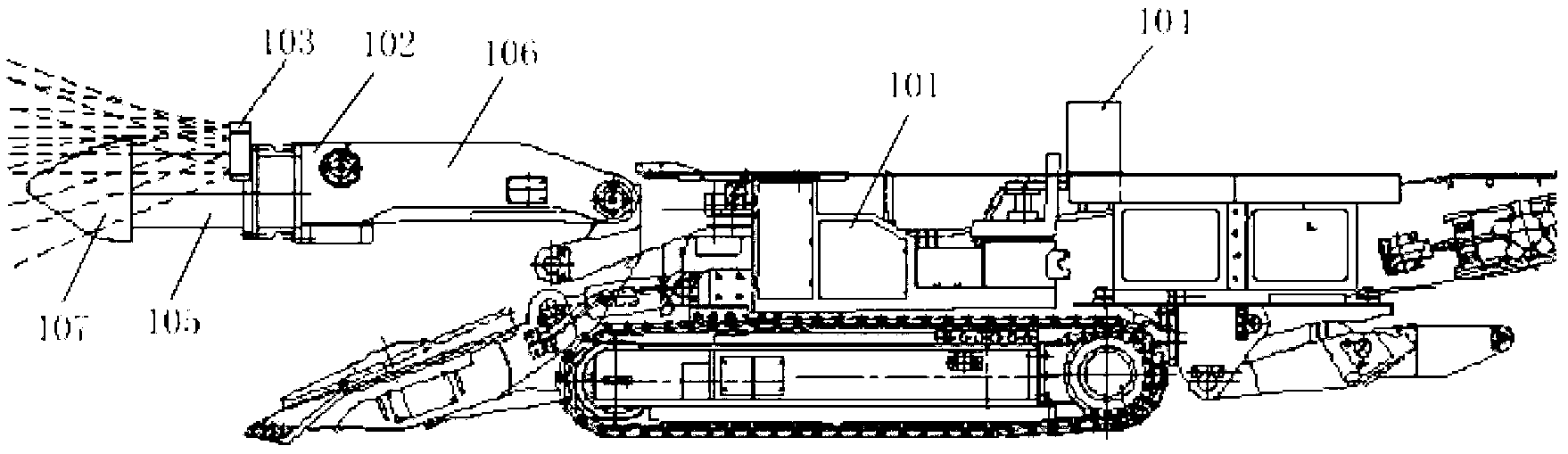

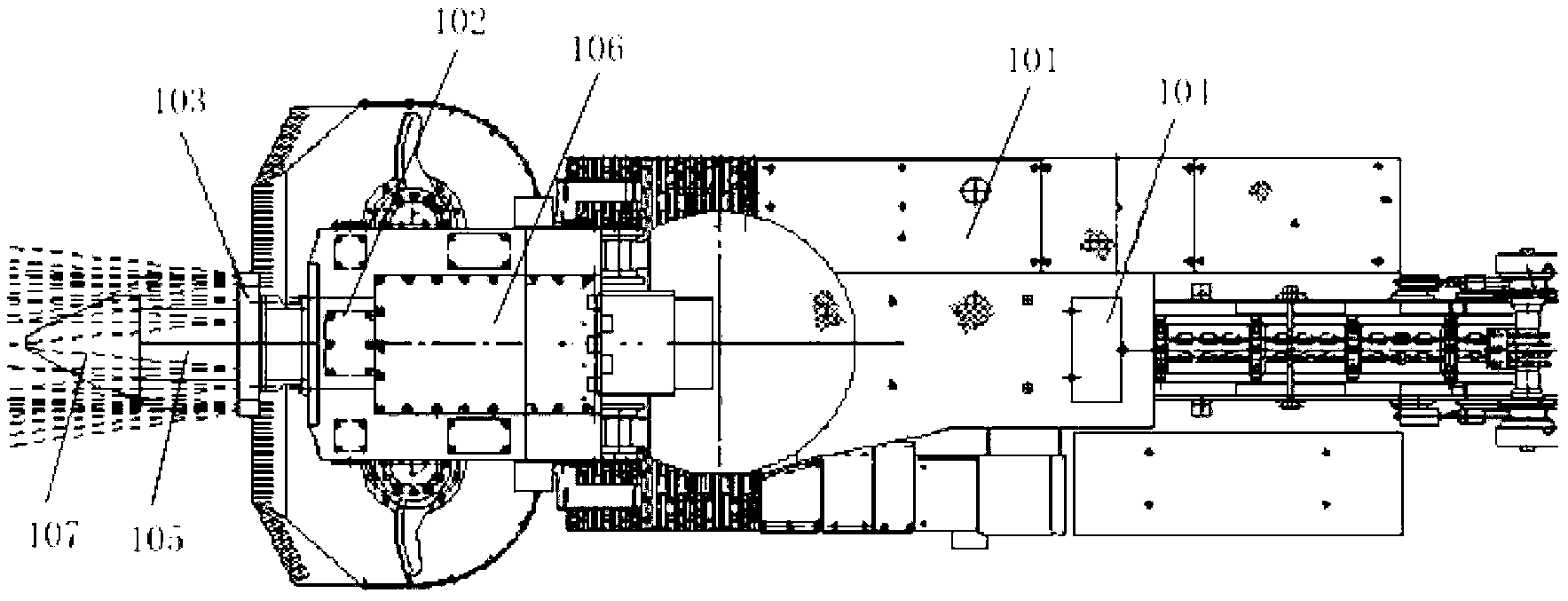

[0016] Please refer to Figure 1-3 , the embodiment of the present invention provides a fully mechanized excavator, comprising: a fuselage 101 with a cutting portion 102; Above, the spray head 103 is connected to the first end of the spray pump 104, and the second end of the spray pump 104 is connected to the water inlet pipeline.

[0017] In this embodiment, because the nozzle 103 of the spraying device is arranged on the cutting part 102, when the cutting part 102 is working, it can directly reduce the dust on the working surface and eliminate the dust at the place where the dust is produced. Meanwhile, because the nozzle 103 is connected There is a spray pump 104, so the low-pressure water supplied to the spray pump 104 can be converted into high-pressure water, and then sprayed into a high-speed atomized flow by the nozzle 103 to spray to the dust source, ensuring the spray range and atomization effect, thereby effectively reducing the generation of dust.

[0018] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com