A Thrust Cylindrical Roller Bearing with Interchangeability and No Fitting Tolerance Required

A cylindrical roller bearing without installation technology, applied in the field of bearings, can solve the problems of the thrust cylindrical roller bearing cannot be used normally, the processing cost of the thrust cylindrical roller bearing is increased, and the shaft washer 2 and the seat washer 5 cannot be used interchangeably. , to achieve the effect of expanding the scope of use, simple structure, reducing processing and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

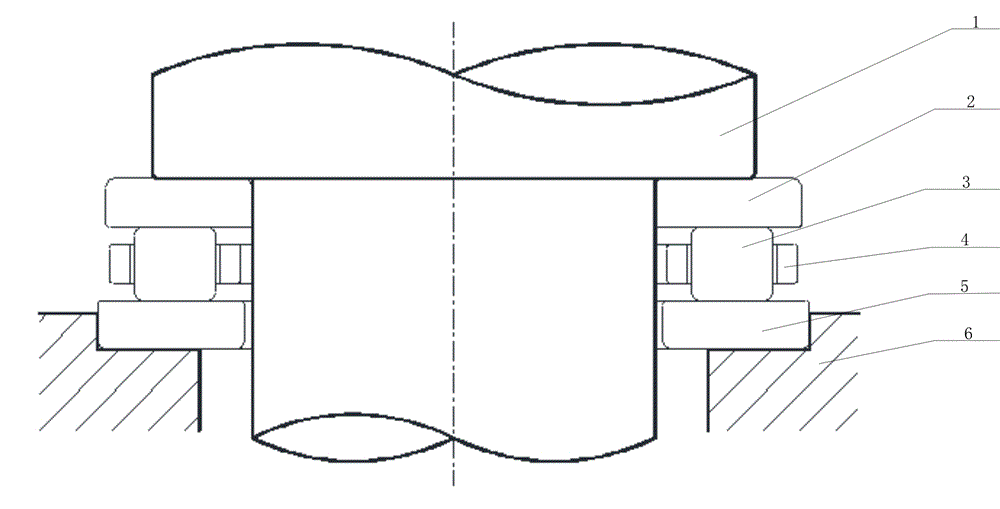

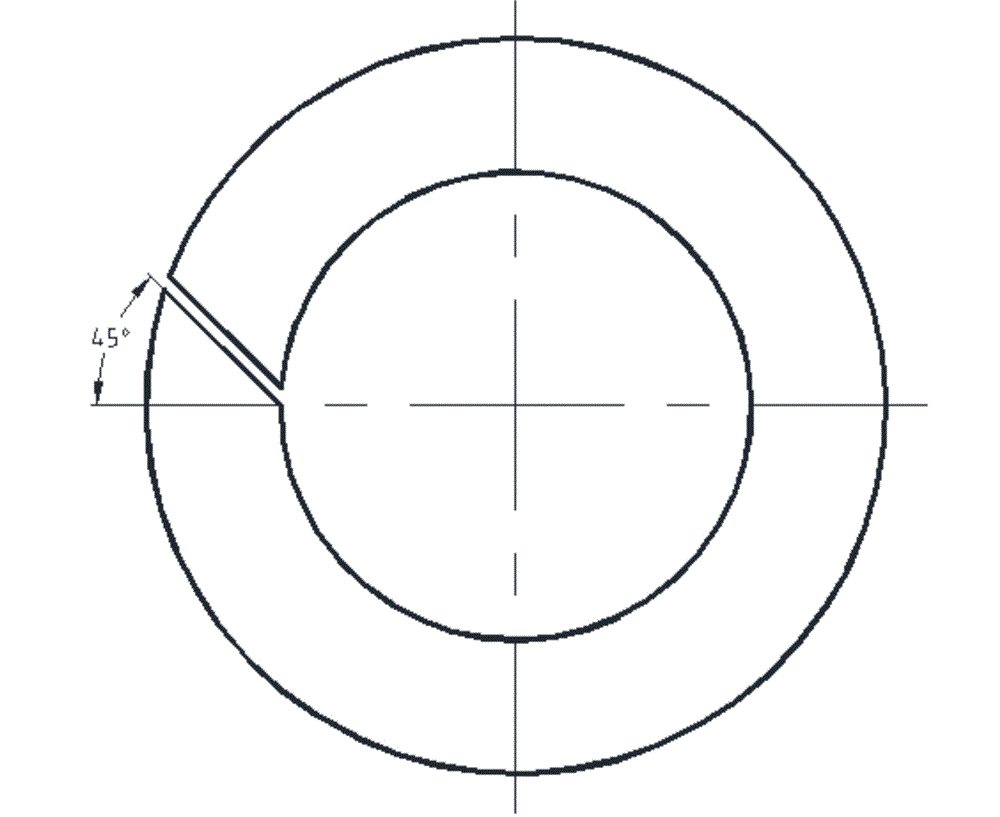

[0018] The present invention is a thrust cylindrical roller bearing which is interchangeable and does not require installation and matching tolerances. The first turning circle and the second turning circle have the function of interchangeable installation positions. Both the first turning circle and the second turning circle have a 45° cutout. The elastic deformation of the 45° notch can realize the installation of the first turning circle, the second turning circle, the limit circle and the shaft seat without fit and tolerance. The installation conditions are not limited by the occasion, and it is very convenient to disassemble or install.

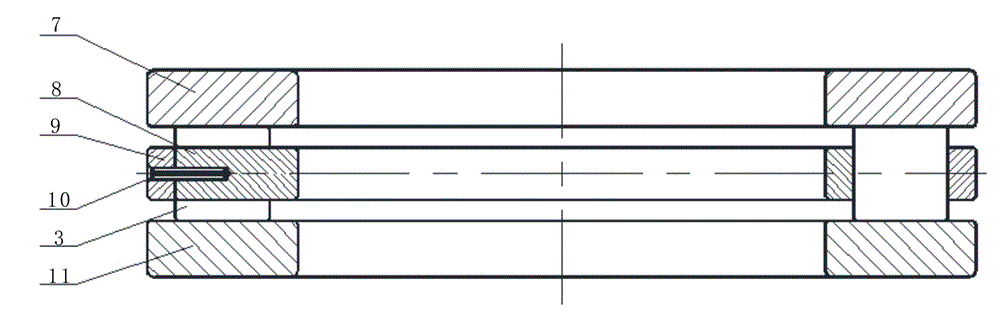

[0019] combine Figure 2-4 , The thrust cylindrical roller bearing of the present invention includes a roller 3 , a first rotating ring 7 , a cage with pockets 8 , an outer ring of the cage 9 , a cylindrical pin 10 , a second rotating ring 11 and a limit ring 12 .

[0020] combine Figure 4 , holding pockets, 8 is equipped with several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com