Auxiliary support for vertical magnetic suspension flywheel rotor

A flywheel rotor and magnetic levitation technology, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of difficult gap size, impact on rotor magnetic levitation, shock and vibration, etc., to reduce shock and vibration, extend The effect of life and safety reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

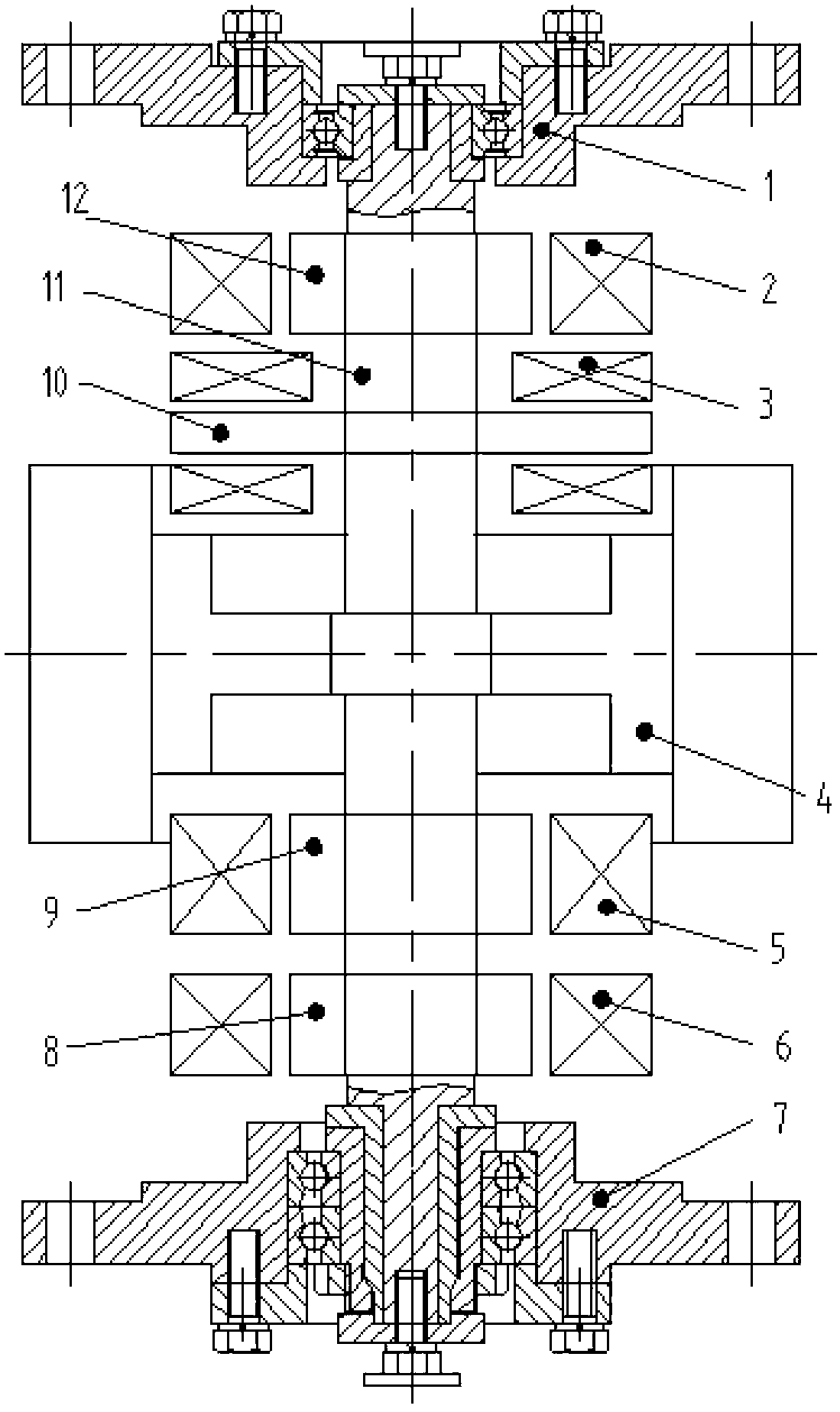

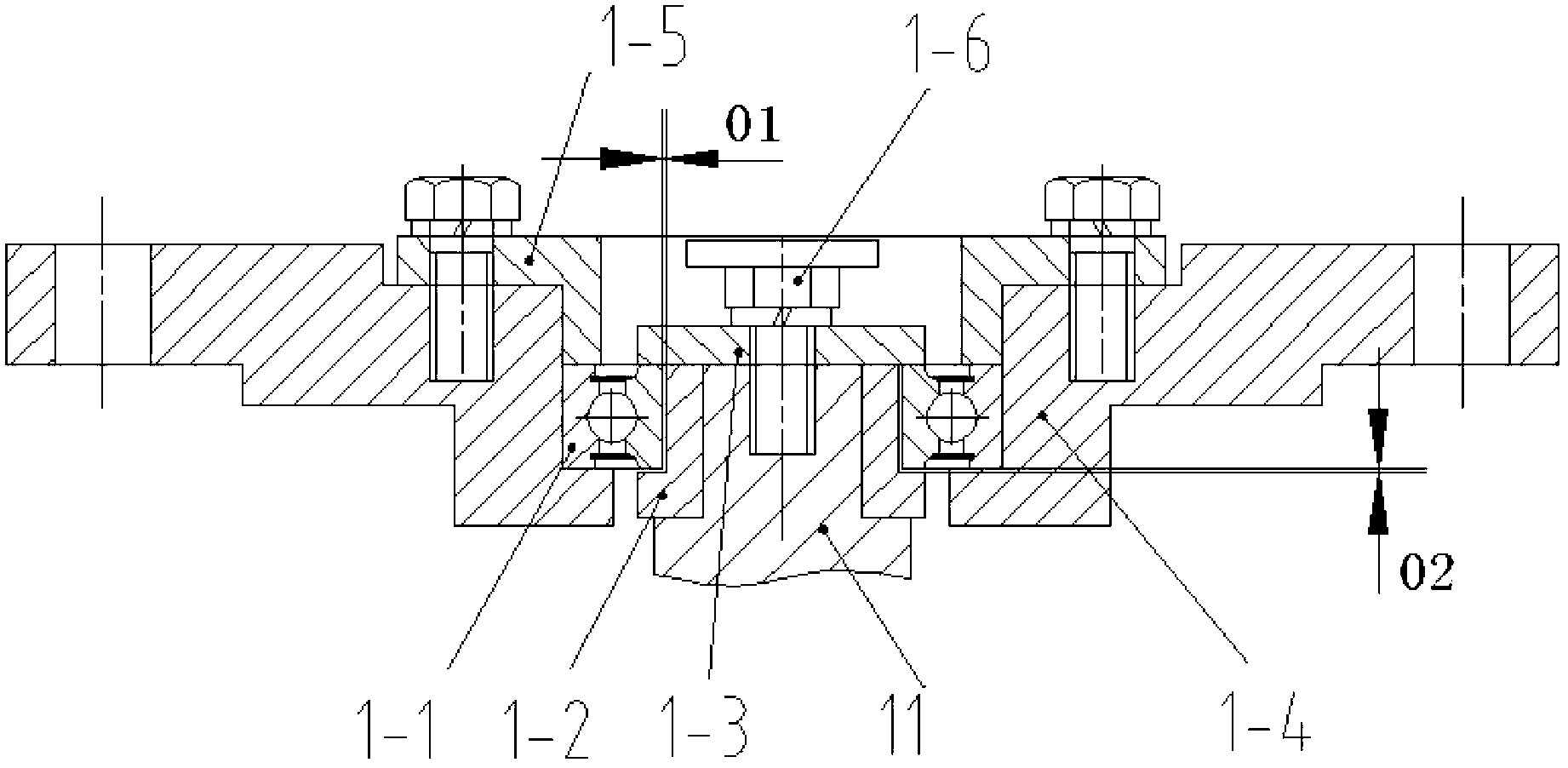

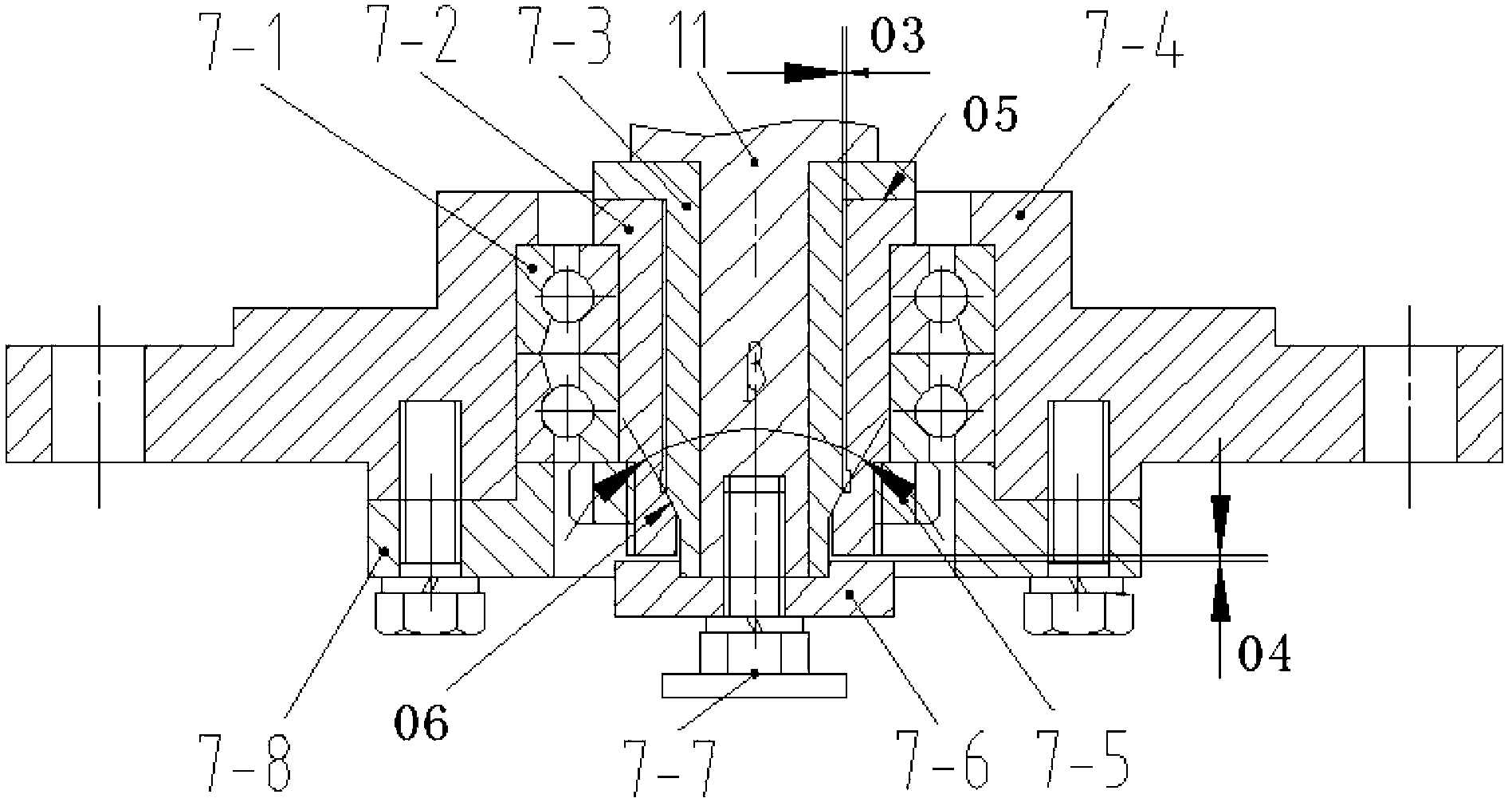

[0015] figure 1 It shows the position and structure of a vertical maglev flywheel rotor auxiliary support in the maglev energy storage flywheel system; it includes an upper auxiliary support assembly 1, an upper radial magnetic bearing stator coil 2, an axial magnetic bearing stator coil 3, a flywheel hub and Composite material rim 4, motor / generator stator coil 5, lower radial magnetic bearing stator coil 6, lower auxiliary support assembly 7, lower radial bearing rotor 8, motor / generator stator 9, axial magnetic bearing thrust disc 10 , flywheel rotor shaft 11, upper radial bearing rotor 12. Among them, the flywheel hub and composite material rim 4, the lower radial bearing rotor 8, the motor / generator stator 9, the axial magnetic bearing thrust disc 10, and the upper radial bearing rotor 12 are all mounted on the flywheel rotor shaft 11 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com