System for adjusting shifting force of manual transmission

A manual transmission and adjustment system technology, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc. Insufficient accuracy and high quality, to achieve the effect of improving the shifting feel, simplifying the design of the shifting suction, and improving the shifting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

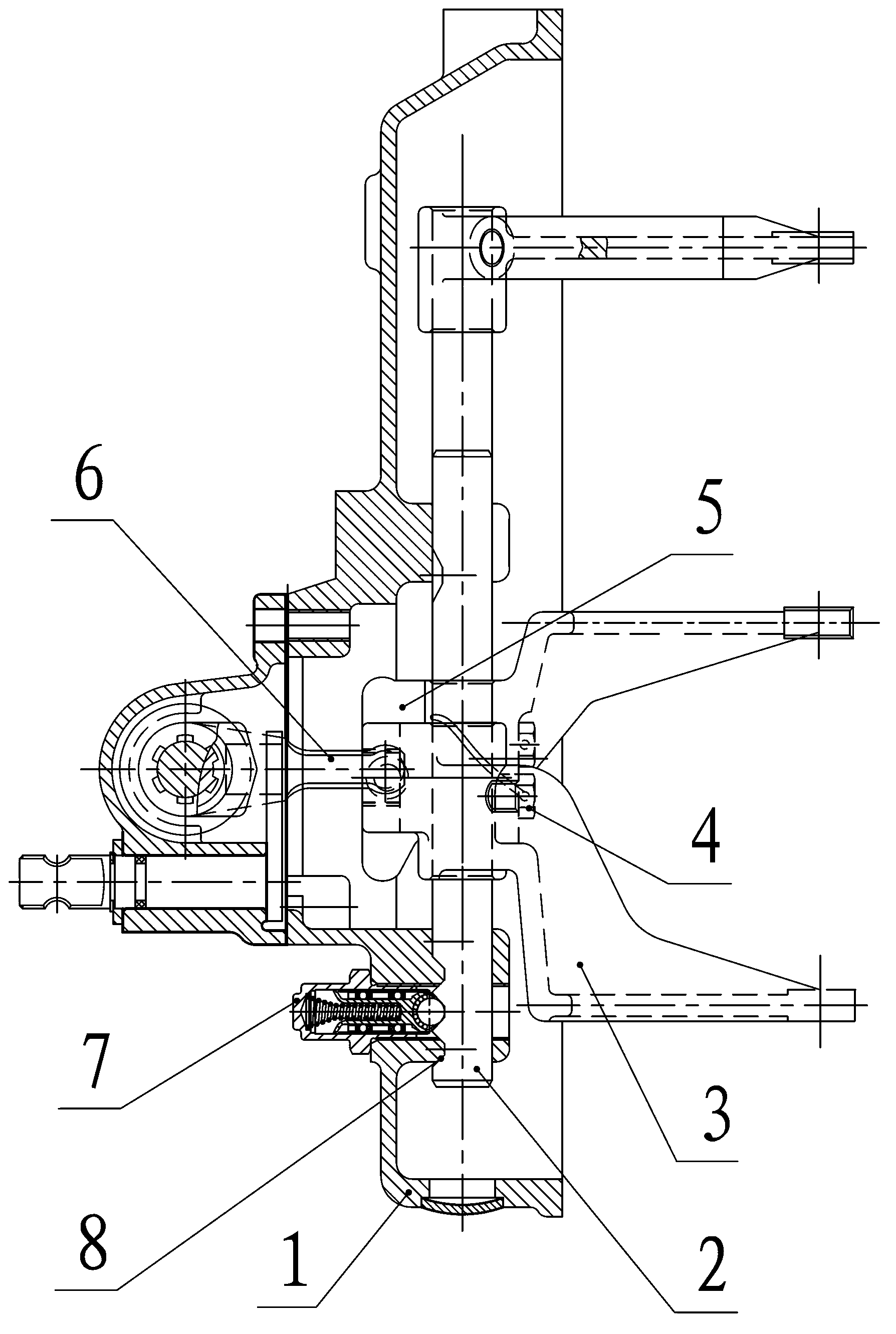

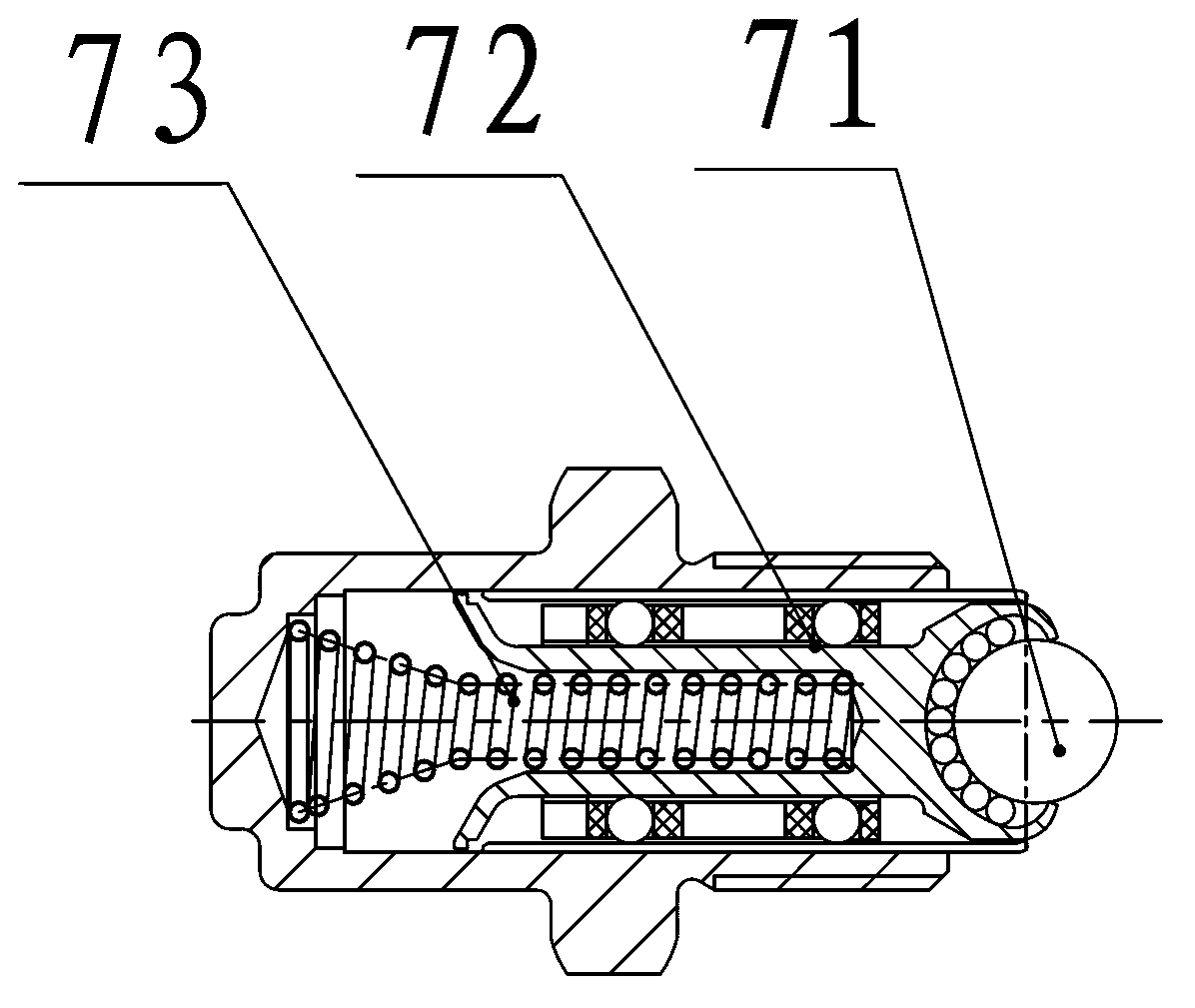

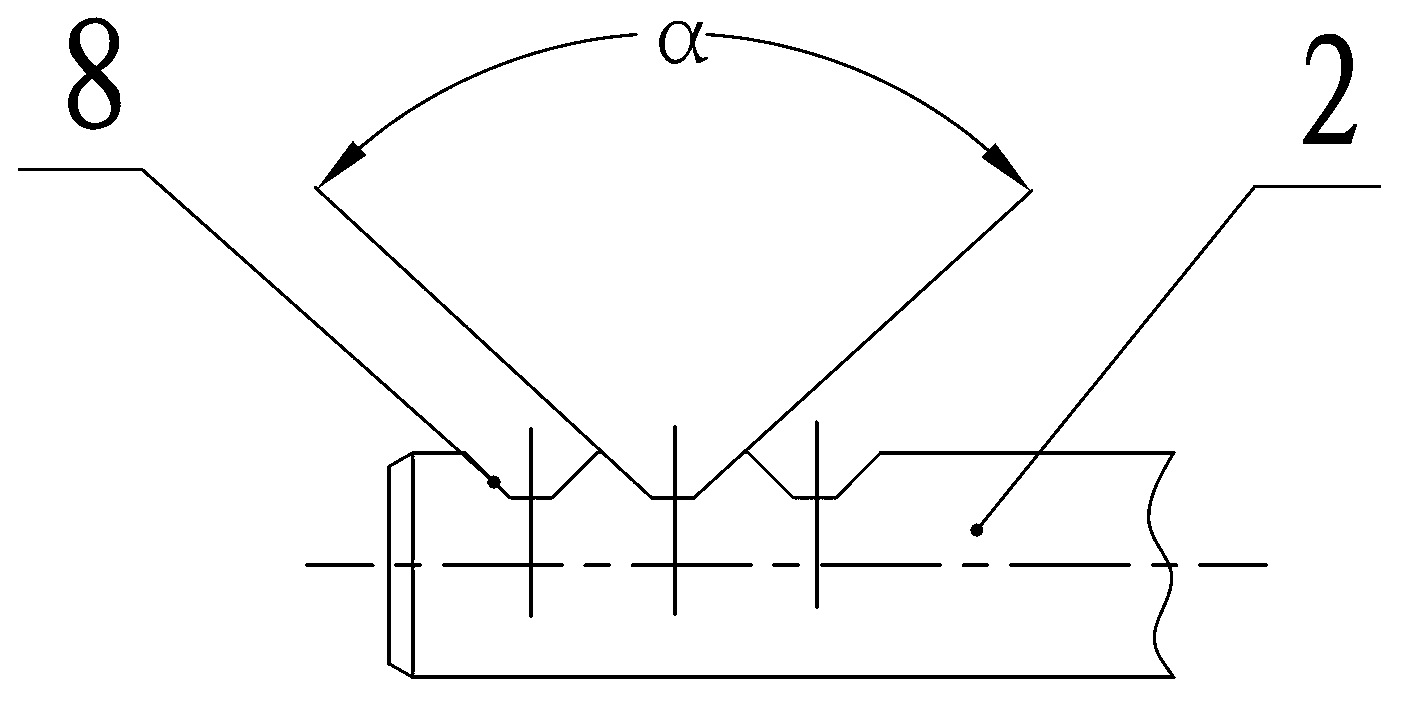

[0015] Such as figure 1 , 2 As shown, an adjustment system for transmission shift force is composed of two independent subsystems, one is a shift execution system, and the subsystem includes an upper cover 1, a fork shaft 2, a shift fork 3, a tightening Fixing screw 4, guide block 5, shift dial 6 and other parts, the shift fork 3 and guide block 5 are fastened on the fork shaft 2 through the fastening screw 4, and the fork shaft 2 is installed on the upper cover 1, which is responsible for the shifting of the transmission. The specific execution of the blocking operation. Through the rotation of the shift dial 6, the shift dial 6 drives the guide block 5, the fork shaft 2, and the shift fork 3 to move along the axial direction of the transmission, and finally drives the transmission to realize gear shifting. The other is the shifting force adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com