Birefringent crystal temperature compensation based optic fiber pressure sensor and production method thereof

A technology of birefringent crystals and pressure sensors, which can be used in the measurement of fluid pressure, the measurement of fluid pressure using optical methods, and the measurement of the force of changes in optical properties of materials when they are stressed, which can solve the inconvenience of practical operation and the cost of instruments. High, complex data processing and other issues, to achieve the effect of convenient practical operation, simple demodulation system, and accurate data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

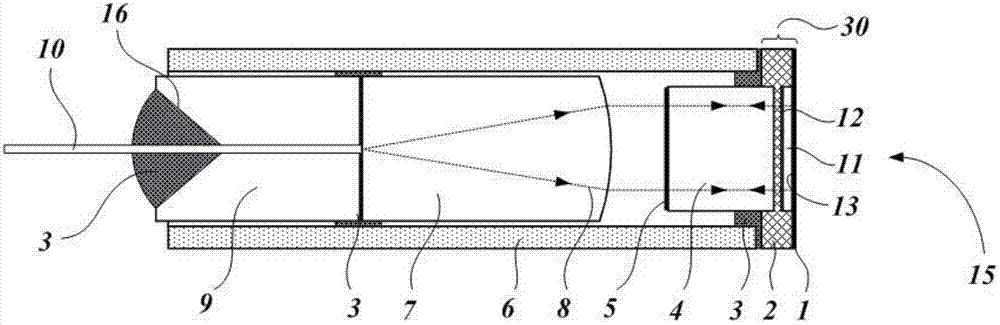

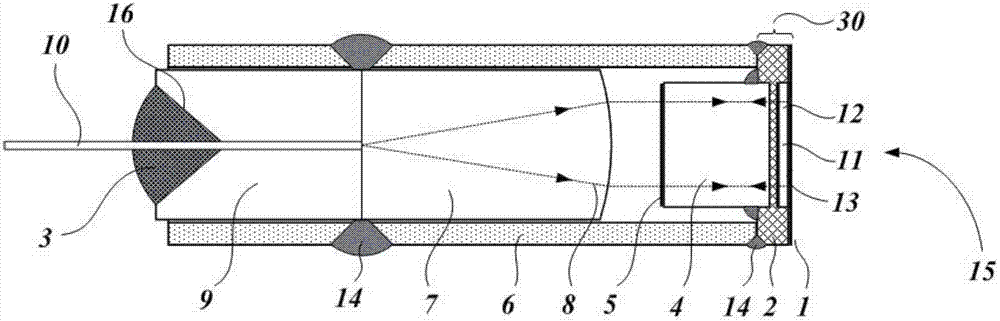

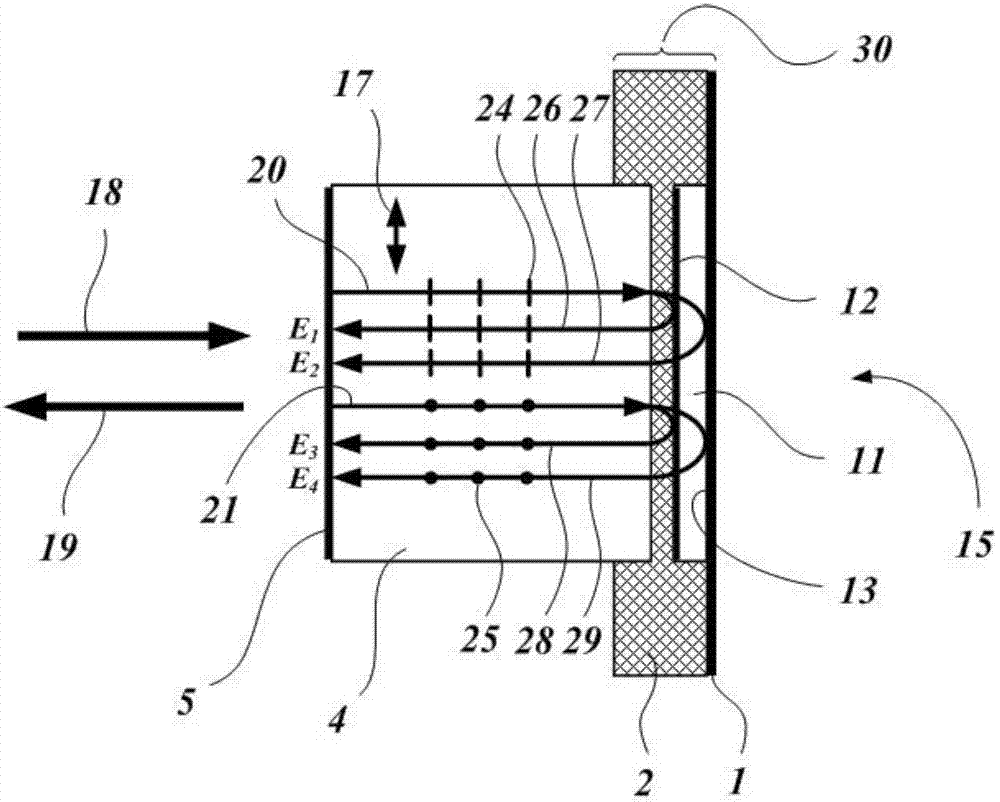

[0031] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The fiber optic Fabry pressure sensor of the invention has the advantage of integrating pressure sensing and temperature measurement. The dual-parameter measurement of pressure and temperature is realized simultaneously by using fiber-optic faber and birefringent crystal. And the temperature measurement result is introduced as a reference quantity, and the pressure measurement result is further corrected to realize high-precision measurement of temperature and pressure. In the present invention, however, the change characteristics of the Faper cavity length are affected by temperature, and without temperature compensation, the pressure measurement accuracy is limited by the characteristics of the sensor.

[0033] The following are descriptions of specific embodiments of the present invention.

[0034] Sensing process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com