Optical fiber high-temperature stress sensor based on yttrium aluminum garnet crystal derived optical fiber and preparation method of optical fiber high-temperature stress sensor

A technology of yttrium aluminum garnet and stress sensor, applied in instruments, measuring devices, etc., can solve problems such as cross-interference, and achieve the effects of high melting point, low preparation cost, stable chemical properties and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

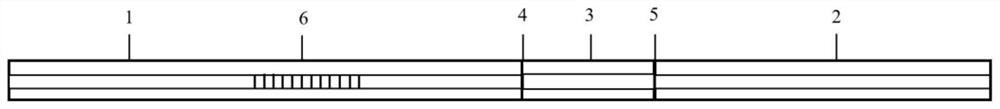

[0030] The invention discloses an optical fiber high temperature stress sensor based on yttrium aluminum garnet crystal-derived optical fiber, comprising a first single-mode optical fiber 1, a second single-mode optical fiber 2, a yttrium aluminum garnet crystal-derived optical fiber 3, and a first fusion surface 4, The second fusion splicing surface 5 and the fiber Bragg grating 6; in this embodiment, the fiber Bragg grating is provided on the first single-mode fiber 1, and the two ends of the yttrium aluminum garnet crystal-derived fiber 3 are connected to the first single-mode fiber 1, the second fiber Bragg grating Two single-mode optical fibers are fused in two phases, and the fusion surfaces are the first fusion surface 4 and the second fusion surface 5 respectively. The first fusion surface 4 and the second fusion surface 5 are used as two reflecting surfaces and the yttrium aluminum garnet crystal-derived fiber 3 is common Form a fiber-optic Fabry-Perot interferometer. ...

Embodiment 2

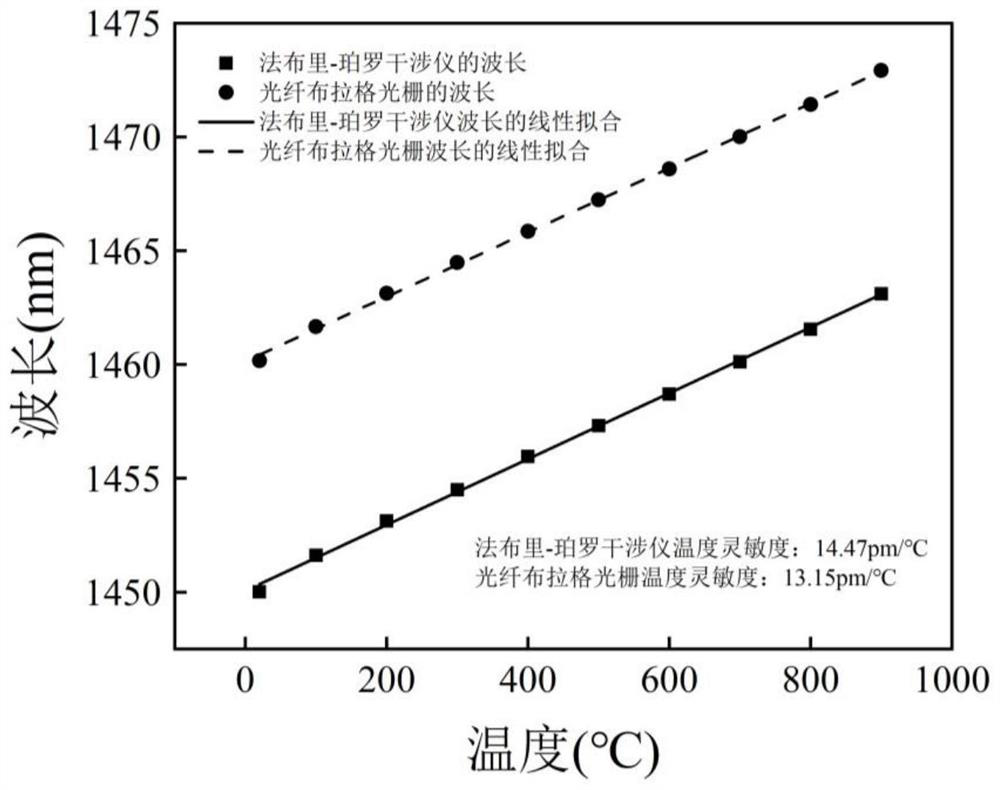

[0045] This embodiment provides a temperature response test of an optical fiber high temperature stress sensor based on yttrium aluminum garnet crystal-derived optical fiber, including the following steps:

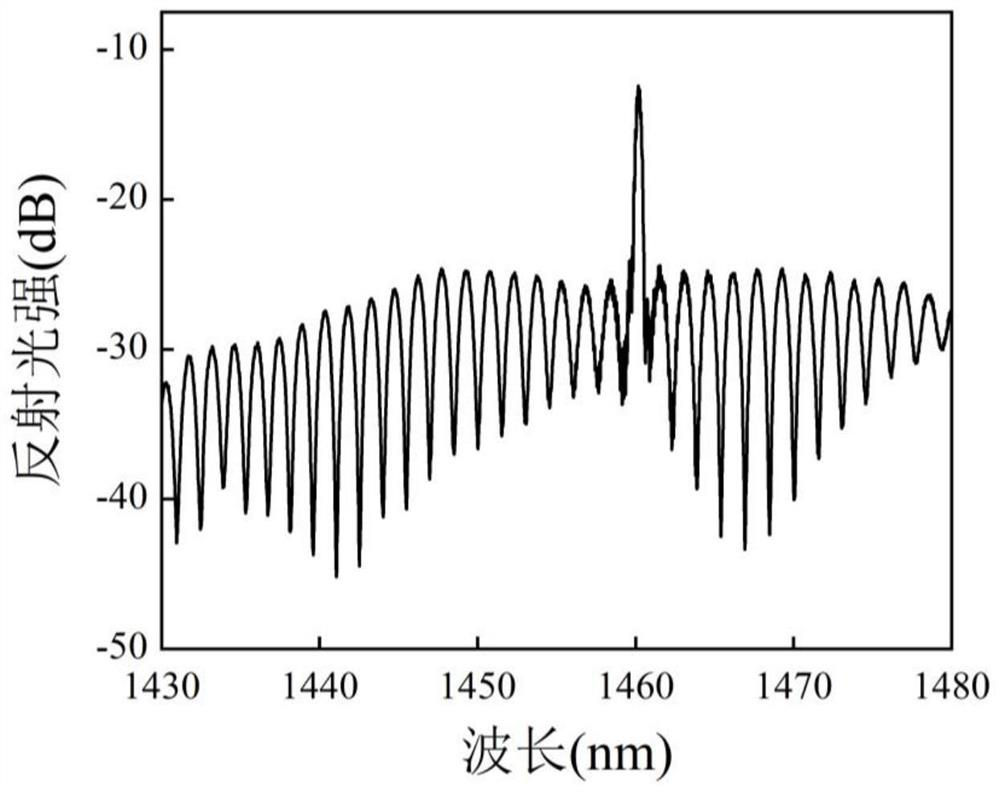

[0046] (1) Connect the single-mode fiber 1 of the high-temperature stress sensor to a fiber coupler, and the other ends of the fiber coupler are connected to a broadband light source (Denmark NKT Photonics, Superk Compact) and a spectrum analyzer (Japan Yokogawa, AQ6370B). Among them, the broadband light source outputs supercontinuum light, and the spectrum analyzer is used to monitor the reflection spectrum, and set its wavelength resolution to 20pm and the wavelength scanning range to 1430-1480nm.

[0047] (2) The high temperature stress sensor is placed in a CINITE tube furnace (CINITE, QSK-5-17) for heating, and the temperature resolution of the CINITE tube furnace is ±0.1°C. The temperature characteristics were demonstrated at 100°C temperature intervals between room ...

Embodiment 3

[0050] This embodiment provides a stress response test of an optical fiber high temperature stress sensor based on yttrium aluminum garnet crystal-derived optical fiber at room temperature, including the following steps:

[0051] (1) Fix one end of the single-mode fiber 1 of the high-temperature stress sensor, and apply an axial tensile force to the other end of the single-mode fiber 2. The stress measuring instrument can monitor the stress exerted on the sensor in real time.

[0052] (2) Connect the single-mode fiber 1 of the high-temperature stress sensor to a fiber coupler, and the other ends of the fiber coupler are connected to a broadband light source (Superk Compact from NKT Photonics, Denmark) and a spectrum analyzer (AQ6370B from Yokogawa, Japan). Among them, the broadband light source outputs supercontinuum light, and the spectrum analyzer is used to monitor the reflection spectrum, and set its wavelength resolution to 20pm and the wavelength scanning range to 1430-14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com