A miniature high-sensitivity optical fiber interferometric pressure sensor and its manufacturing method

A pressure sensor and optical fiber interference technology, which is applied in the direction of using optical devices to transmit sensing components, measure fluid pressure, instruments, etc., can solve problems such as low precision, temperature cross-sensitivity, and limited sensitivity, so as to improve sensitivity and measurement range , to avoid the effect of temperature cross-effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through implementation. Other aspects, features and advantages of the present invention will become clear through the detailed description.

[0045] The purpose of the present invention is to propose a temperature-compensated micro-high-sensitivity optical fiber interference pressure sensor based on a 2D sensitive material film and a manufacturing method thereof.

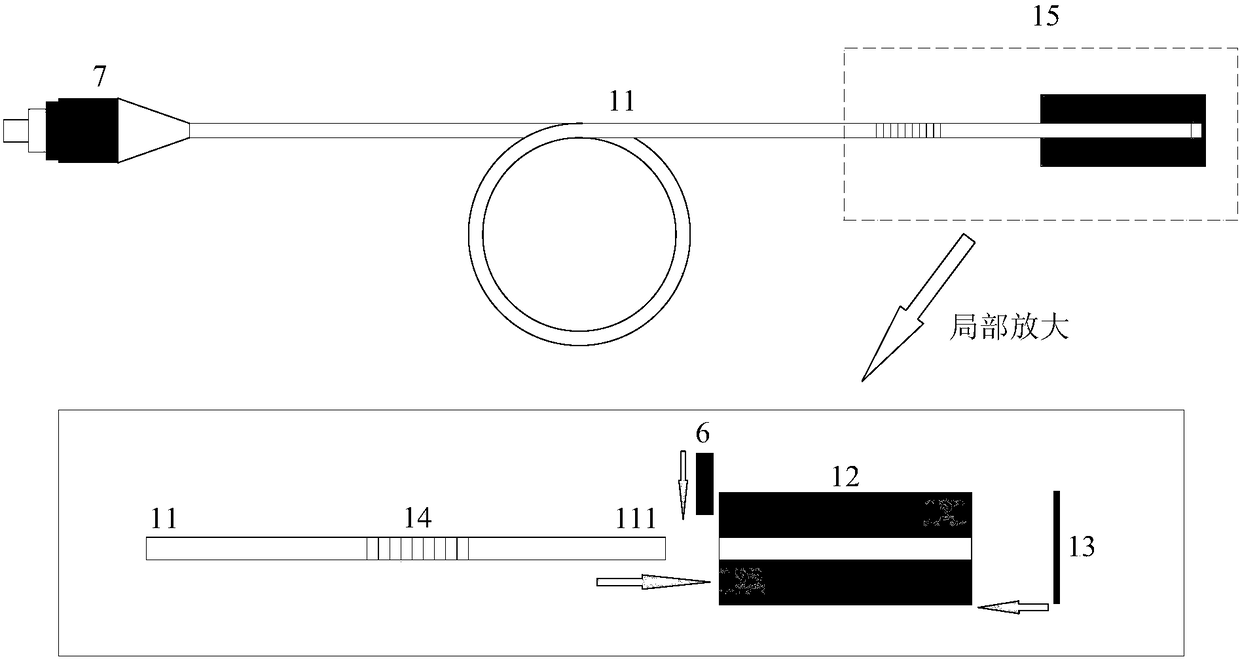

[0046] figure 1 It is a structural schematic diagram of the optical fiber interferometric pressure sensor based on the 2D sensitive material thin film of the present invention. The sensor probe part 15 is mainly composed of a single-mode optical fiber 11 , a fiber ferrule 12 , a 2D sensitive material film 13 and a Bragg grating 14 . The single-mode optical fiber 11 is an optical fiber connector with a single-mode pigtail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com