Liquid crystal display device

A technology of liquid crystal display device and liquid crystal display panel, which is applied to static indicators, nonlinear optics, optics, etc., can solve the problems of difficult design and difficult to hide of borderless liquid crystal display devices, and achieves easy design and realization of borderless. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

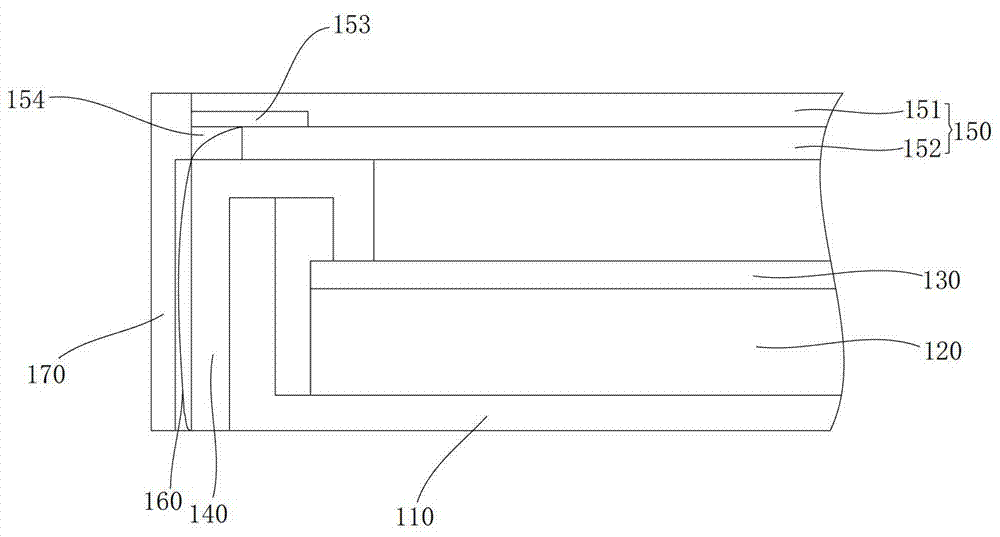

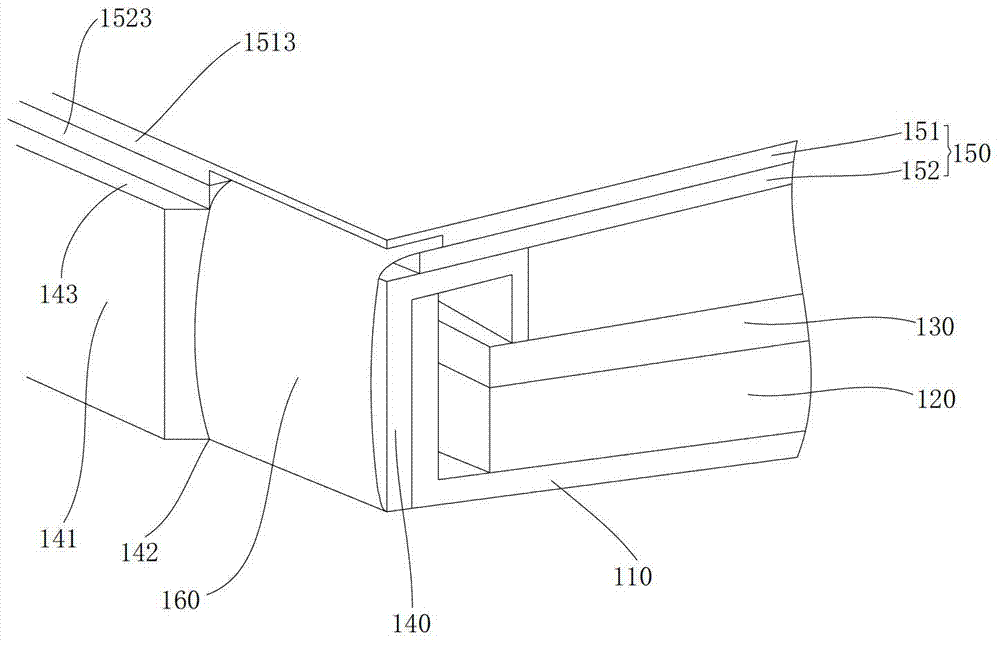

Image

Examples

Embodiment 2

[0044] In the description of Embodiment 2, the same content as Embodiment 1 will not be repeated here. The difference between embodiment 2 and embodiment 1 is that the routing gap of the liquid crystal display panel is changed, the details are as follows.

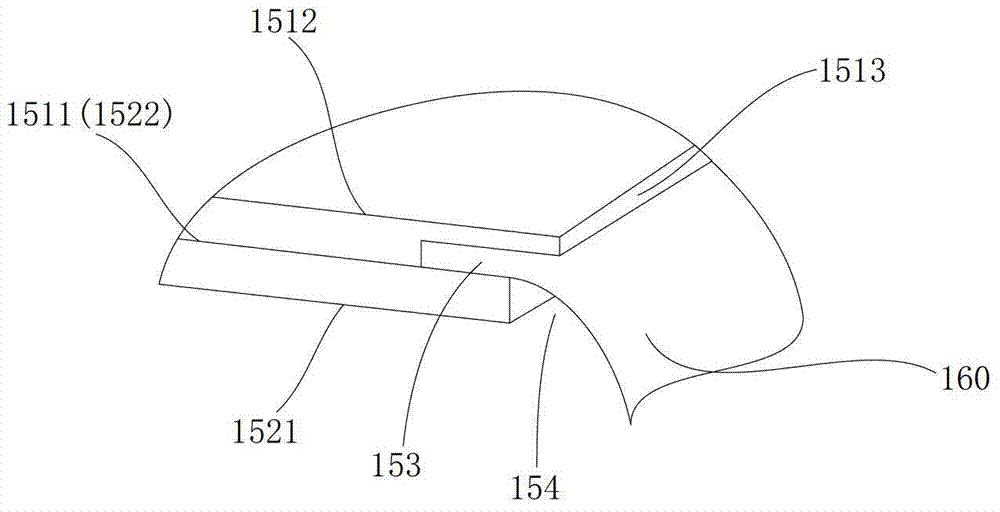

[0045] Figure 8 A partial schematic diagram of a liquid crystal display panel according to Embodiment 2 of the present invention is shown. Figure 9 A partial schematic diagram of a liquid crystal display panel filled with a transparent plate according to Embodiment 2 of the present invention is shown.

[0046] Compared with Example 1, Figure 8 The illustrated liquid crystal display panel 250 according to Embodiment 2 of the present invention includes an upper glass substrate 251 and a lower glass substrate 252 oppositely arranged, wherein the upper glass substrate 251 includes a bottom surface 2511, a top surface 2512, and a side surface 2513 connecting the bottom surface and the top surface , the lower glass substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com