Method of preparing tobacco sheet with agilawood characteristic

A technology of tobacco sheet and agarwood, which is applied in the field of preparing tobacco sheets with agarwood characteristics, can solve problems such as no public reports, and achieve the effect of strong guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with implementation examples, but the present invention is not limited.

[0012] The concrete steps of the inventive method are as follows:

[0013] a. Grind the agarwood raw material, pass it through a 60-mesh sieve, then add 5 times of 50% ethanol to the crushed agarwood raw material according to the weight percentage, and extract under reflux for 3~4 hours at a temperature of 65±5°C, and filter Concentrate extract to obtain extract, stand-by;

[0014] b. Finely grind the residue obtained after extraction and filtration to reach the beating degree requirement of 10-40°SR, and set aside;

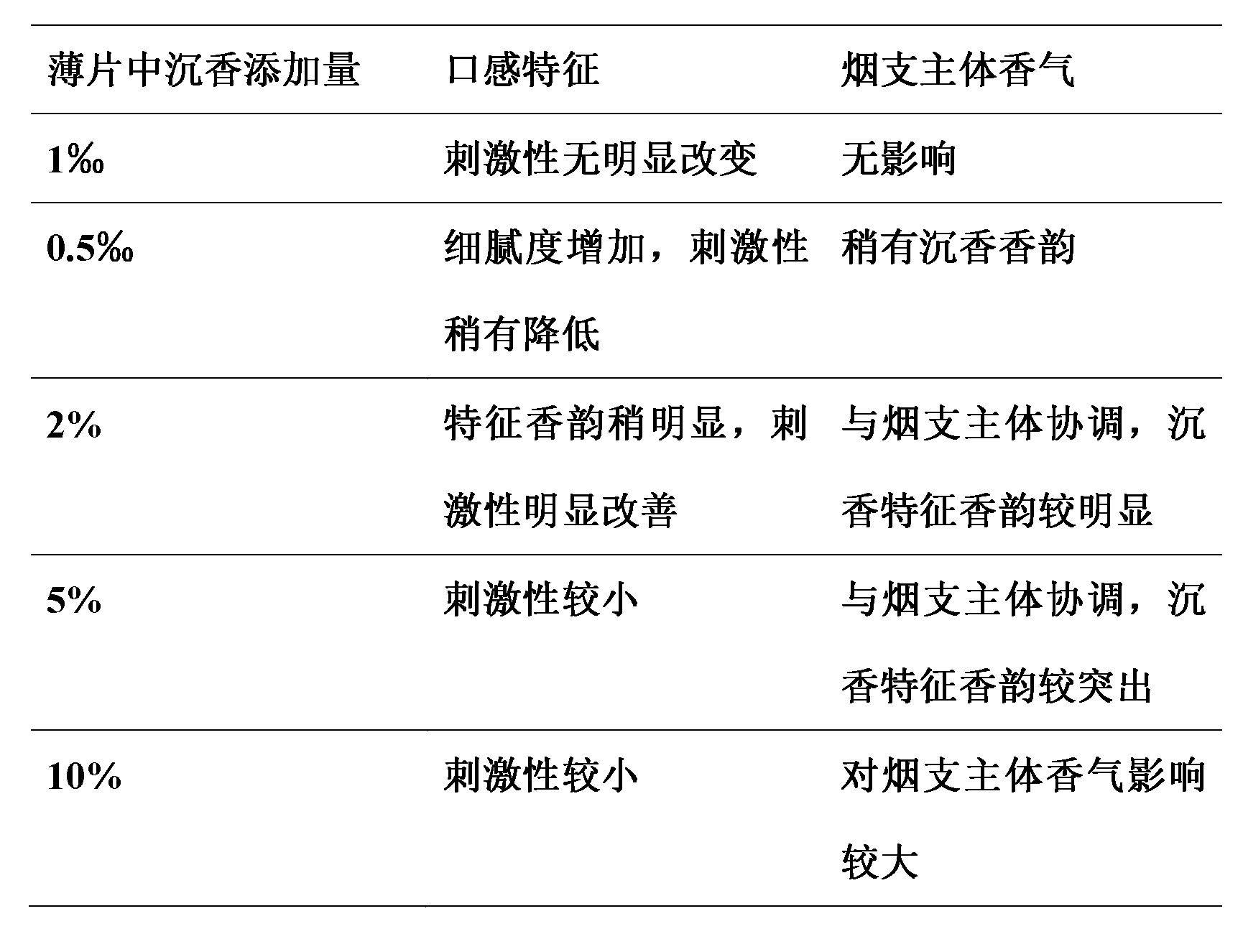

[0015] c. Add the agarwood pulp that has reached the beating degree requirement after fine grinding to the tobacco sheet pulp in the proportion of 1‰~10% by weight, mix evenly to form the tobacco sheet pulp, and produce the required sheet through the tobacco sheet papermaking method;

[0016] d. adding the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com