Blow molding panel and folding table applying same

A technology of blow molding panels and folding tables, which is applied in the field of folding tables, which can solve the problems of low structural strength of the panels, unsightly back of the panels, and bulky blow molding tables, etc., and achieve novel structures, ensure rigidity and strength, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

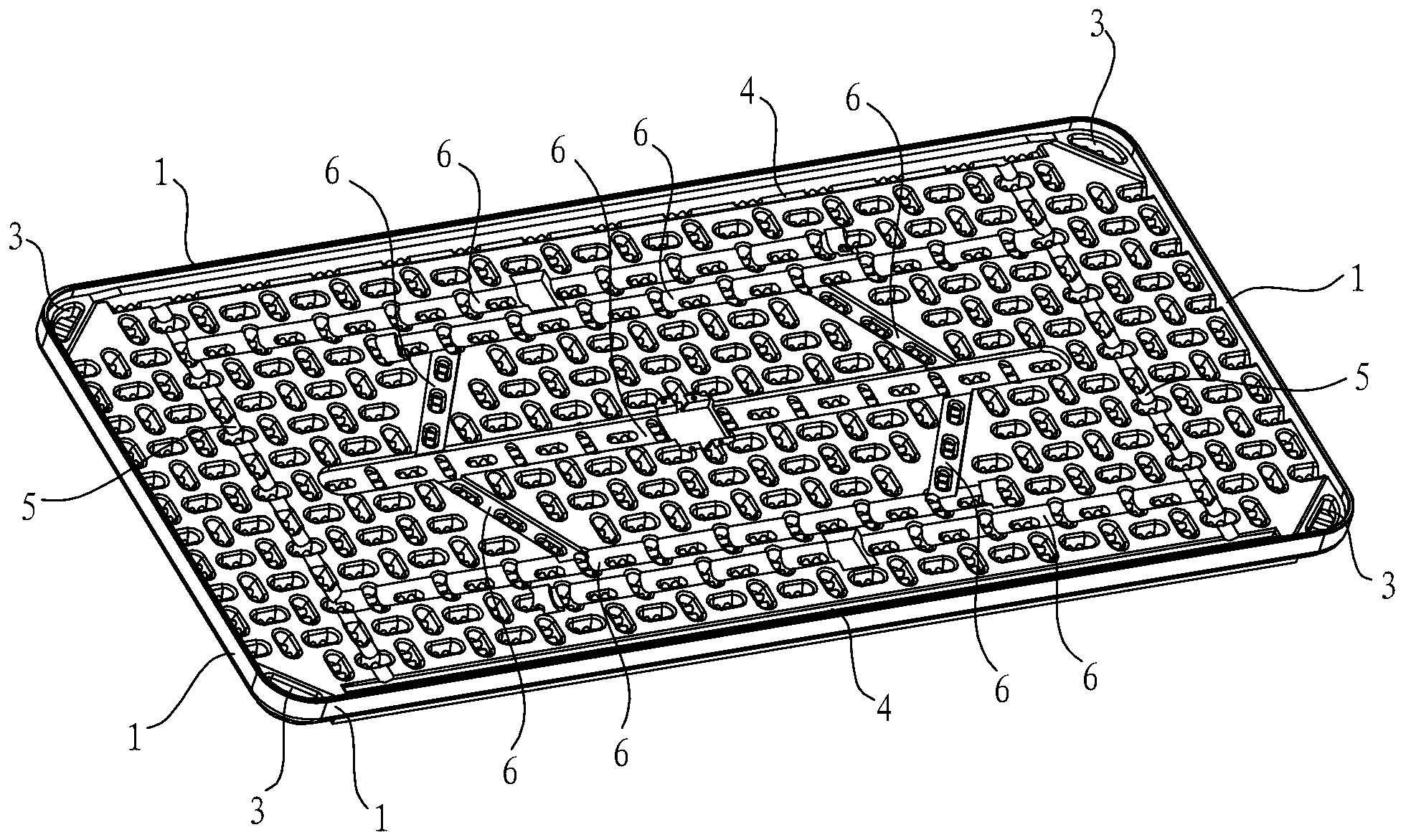

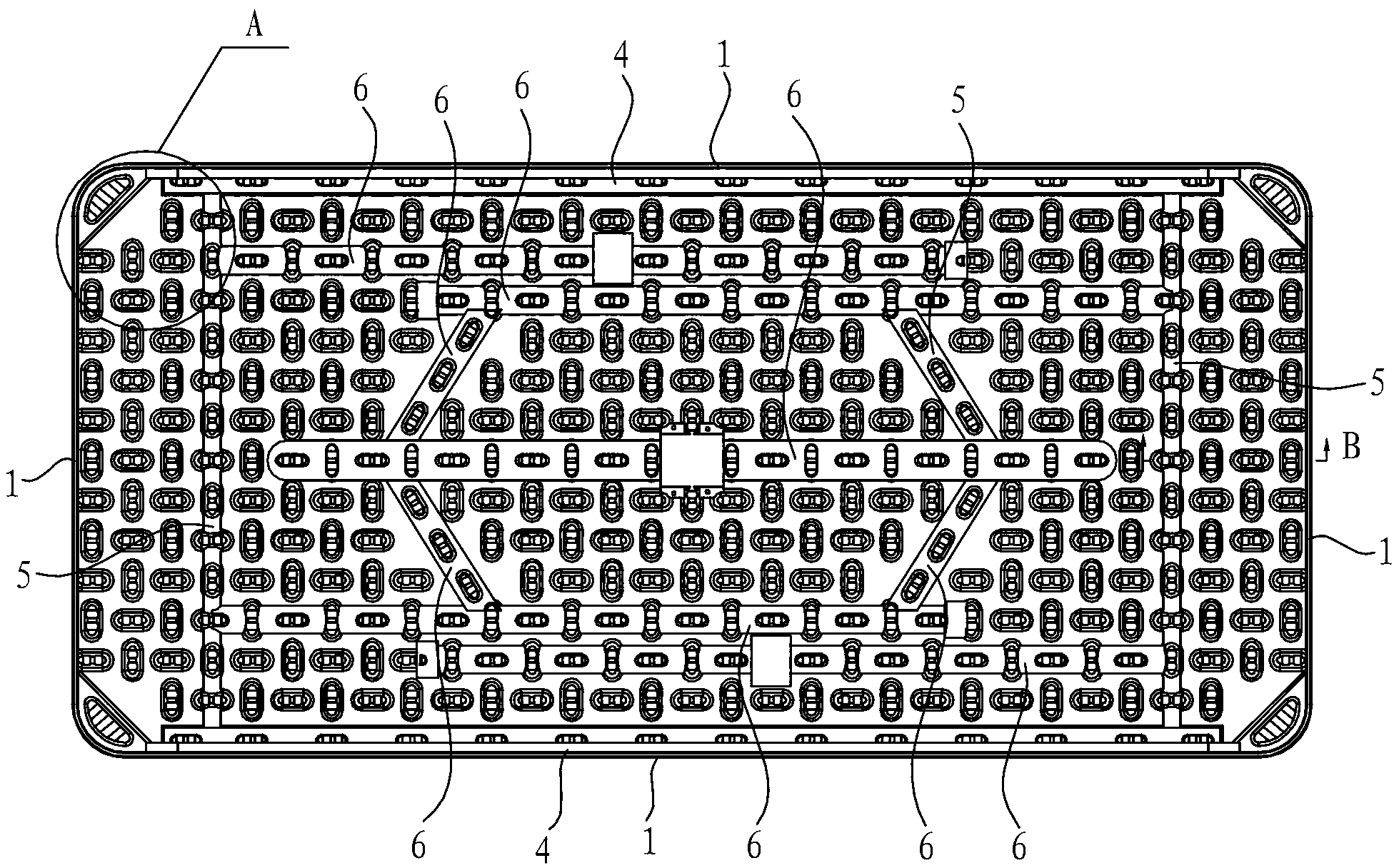

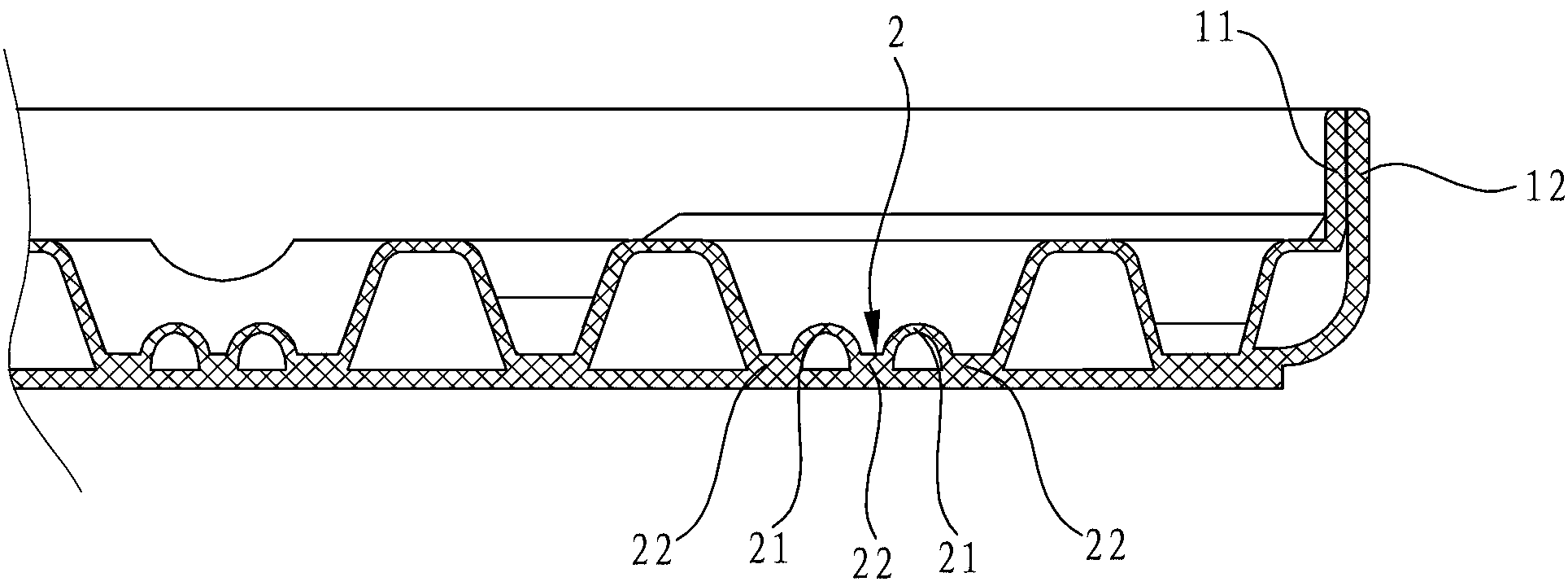

[0025] Such as Figure 1 to Figure 4 As shown, the blow-molded panel in this embodiment is distributed with many depressions on the back and is arranged in a vertical and horizontal staggered manner. The support contact points 2 are in the shape of strips. The external stress in one direction is decomposed into forces that are mutually involved in multiple directions, thereby enhancing the structural strength and twist resistance of the panel itself, and, after adopting the recessed support contact point 2, the wall thickness of the blow-molded panel can be reduced, Reduce the weight of the panel. Especially for ultra-thin (thickness<40MM) boards, after adopting criss-cross support contact points 2, its firmness can be greatly strengthened, making it difficult to deform. In addition, in order to improve the structural strength of the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com