Multifunctional heat exchanging device of crystallizing kettle

A heat exchange device and multifunctional technology, applied in the field of multifunctional heat exchange devices for crystallization kettles, can solve the problems of unsatisfactory heat exchange effect, many materials used, cumbersome installation, etc., and achieve convenient installation and production, fast flow speed, flow short distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

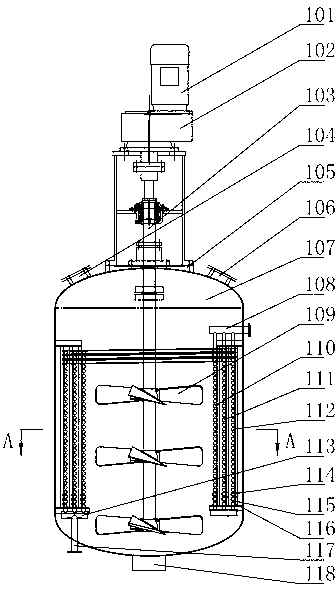

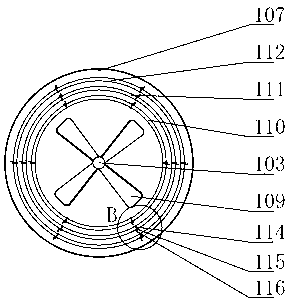

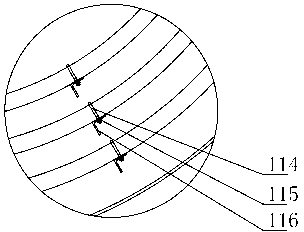

[0026] Such as Figure 4 , Figure 5 and Figure 6 As shown, the crystallization kettle multifunctional heat exchange device of the present embodiment includes a container 107, and a transmission device is installed on the top of the container 107 through a machine base 105. The transmission device includes a motor 101, a reducer 102, and a rotating shaft 103 is installed at the output end of the reducer 102. The rotating shaft 103 stretches into the container 107, and the rotating shaft 103 in the container 107 is equipped with a blade 109; the top of the container 107 is provided with a feed port 106, an observation hole 104, and the bottom of the container 107 is provided with a material outlet 118; the container 107 The upper connecting pipe 19 and the lower connecting pipe 24 are arranged at intervals up and down in the interior, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com