Automatic butterfly chain punching machine and punching processing method

A technology of stamping processing and stamping machine, which is applied in the field of butterfly chain stamping processing of butterfly chain automatic stamping machine, can solve the problems of cumbersome and complicated procedures, time-consuming and labor-intensive yield, and difficult accurate positioning, so as to reduce material wear, improve work performance, The effect of overcoming the feeding error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

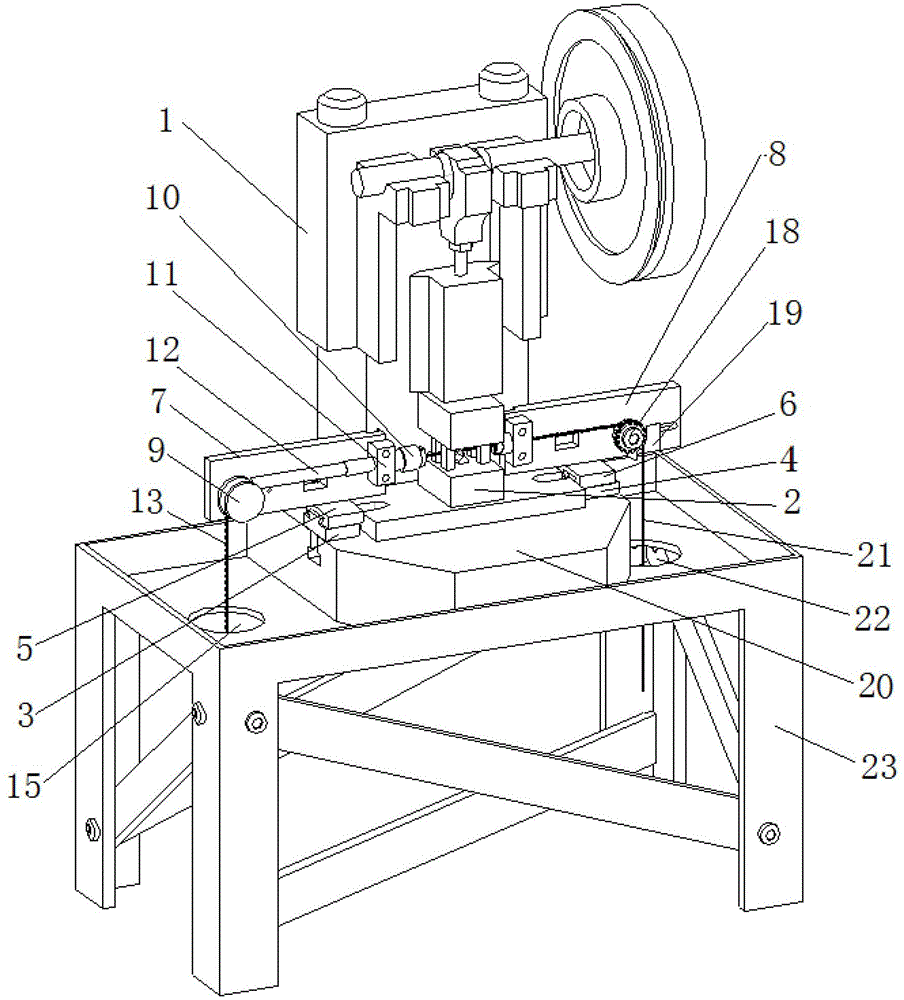

[0038] Embodiment 1: Before the present invention describes in detail the method for punching and processing butterfly chains with a butterfly chain automatic punching machine, first introduce a kind of butterfly chain automatic punching machine used in this processing method, its overall structure is as followsfigure 1 As shown, it at least includes a stamping mechanism, a mounting frame, a detection mechanism, a positioning mechanism, a chain closing mechanism, a stand and a control box.

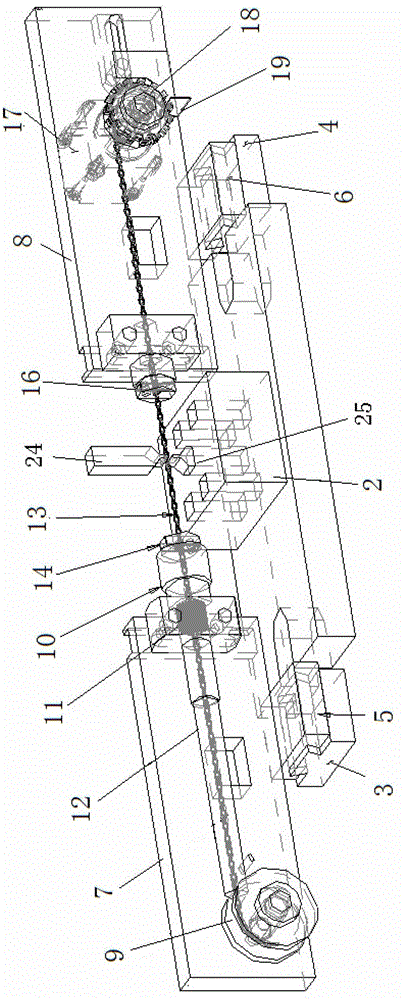

[0039] The stamping mechanism includes a punch 1, an electromagnetic clutch and a stamping die. The electromagnetic clutch is installed on the punching machine as an auxiliary part. The bottom plate of the lower die base of the stamping die 2 is fixed on the stamping workbench 20. There are two upper and lower dies in the die. Punch, the upper punch 24 is installed in the upper die base, and the lower punch 25 is installed in the lower die base; , the left upper chute 5 and the detection en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com