Membrane concentrated water treatment method taking adsorption and ultrasonic regeneration as major technology

A technology of ultrasonic regeneration and treatment methods, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., to achieve the effect of improving biodegradability, simple equipment, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Concentrated water from a petrochemical wastewater membrane process was taken as the membrane concentrated water used in the experiment, and its water quality indicators were: COD 150 mg / L, conductance 4 ms / cm, Cl - 1000mg / L.

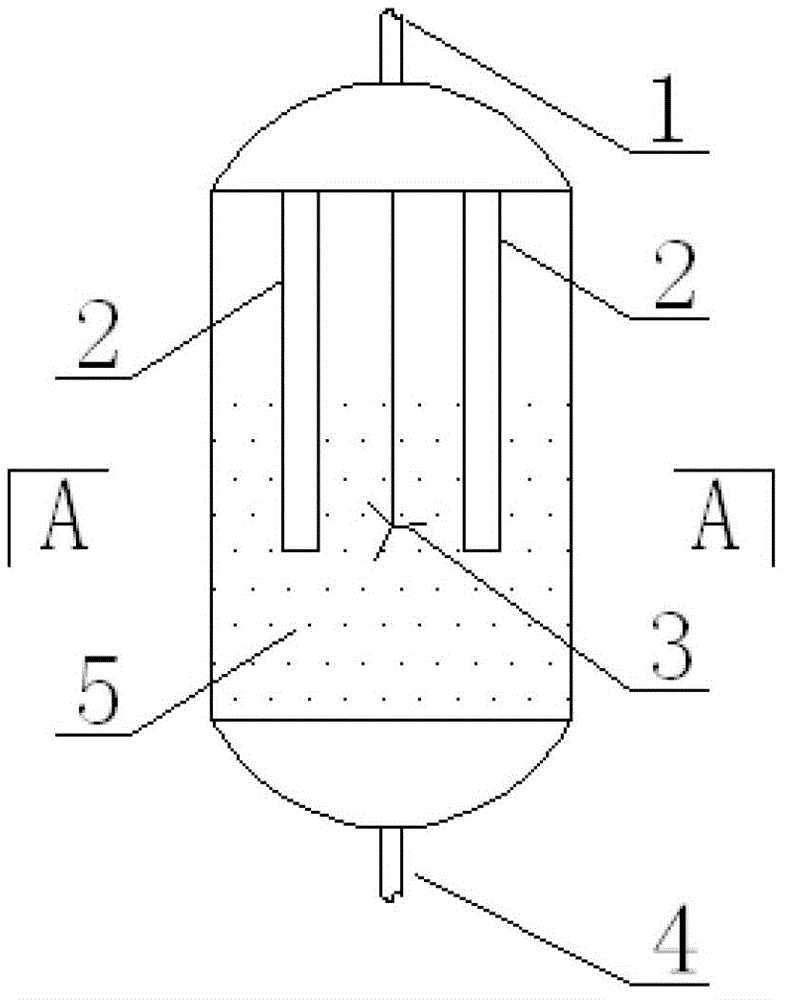

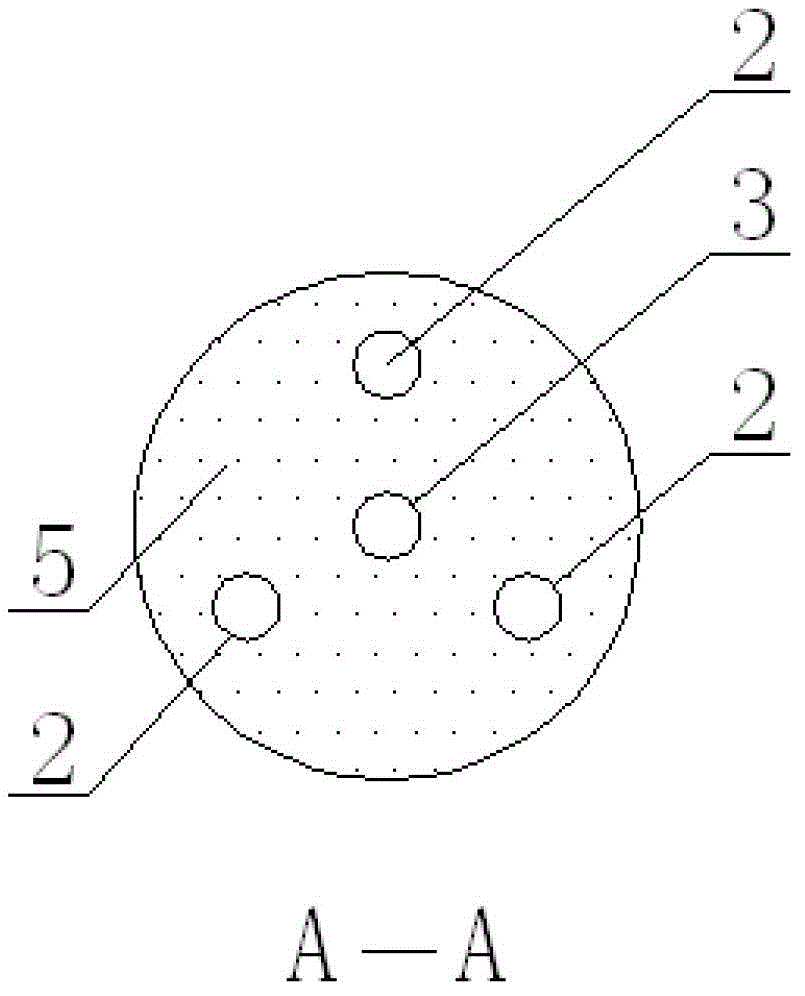

[0025] Using the treatment method of the present invention to treat the concrete steps of the above-mentioned experimental membrane concentrated water is as follows: first, the membrane concentrated water is passed into a single-stage adsorption column equipped with granular activated carbon (structure such as Figure 1-2 As shown), the way of water inlet and outlet is bottom inlet and top outlet, that is, the adsorption water inlet 4 enters from the bottom and fully contacts with the adsorbent, and then the water is discharged from the upper adsorption outlet 1. The hydraulic retention time is adjusted to 10 minutes, and the COD of the outlet water is measured every other column. ; The adsorption column is also provided with a stirrer 3 and an ...

Embodiment 2

[0028] Concentrated water from a certain pharmaceutical wastewater treated by membrane process was used as membrane concentrated water for experimentation, and its water quality indicators were: COD 338 mg / L, conductance 30 ms / cm, Cl - 8000mg / L.

[0029] The specific steps of using the treatment method of the present invention to treat the above-mentioned membrane concentrated water used in the experiment are as follows: first, the membrane concentrated water is passed into a single-stage adsorption column equipped with NDA-800 resin, and the way of entering and leaving the water is from the bottom to the top, and the hydraulic retention time is adjusted. For 30 min, measure the COD of every other column in the effluent; when the adsorption is saturated, stop the adsorption, start the agitator 3 and the ultrasonic transmitter 2, and realize the regeneration of the water in the column and the adsorbent 5 in a mixed state, and the ultrasonic frequency is controlled at 350 KH Z...

Embodiment 3

[0032] Concentrated water from a certain chemical wastewater treated by membrane was taken as the experimental wastewater, and its water quality indicators were: COD 500 mg / L, conductance 16.5 ms / cm, Cl - 4040 mg / L.

[0033] The specific steps of using the treatment method of the present invention to treat the above-mentioned wastewater are as follows: firstly, the membrane concentrated water is passed into a single-stage granular activated carbon adsorption column, the way of entering and exiting the water is from the bottom to the top, and the hydraulic retention time is adjusted to be 60 min. One column measures COD; when the adsorption is saturated, stop the adsorption, start the stirrer 3 and the ultrasonic transmitter 2, and realize the regeneration of the water and the adsorbent 5 in the column in a state of mixing, and the ultrasonic frequency is controlled at 750 KH Z , the ultrasonic time is controlled at 5 min, and the ultrasonic sound intensity is controlled at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com