Red-mud-based nitrogen phosphorus controlled release agent and preparation method thereof

A slow-release and controlled-release technology, which is used in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of limited long-term and continuous control ability, low product dosage, and physical and chemical properties restrictions, and achieve good economy. , The effect of rich raw material source and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

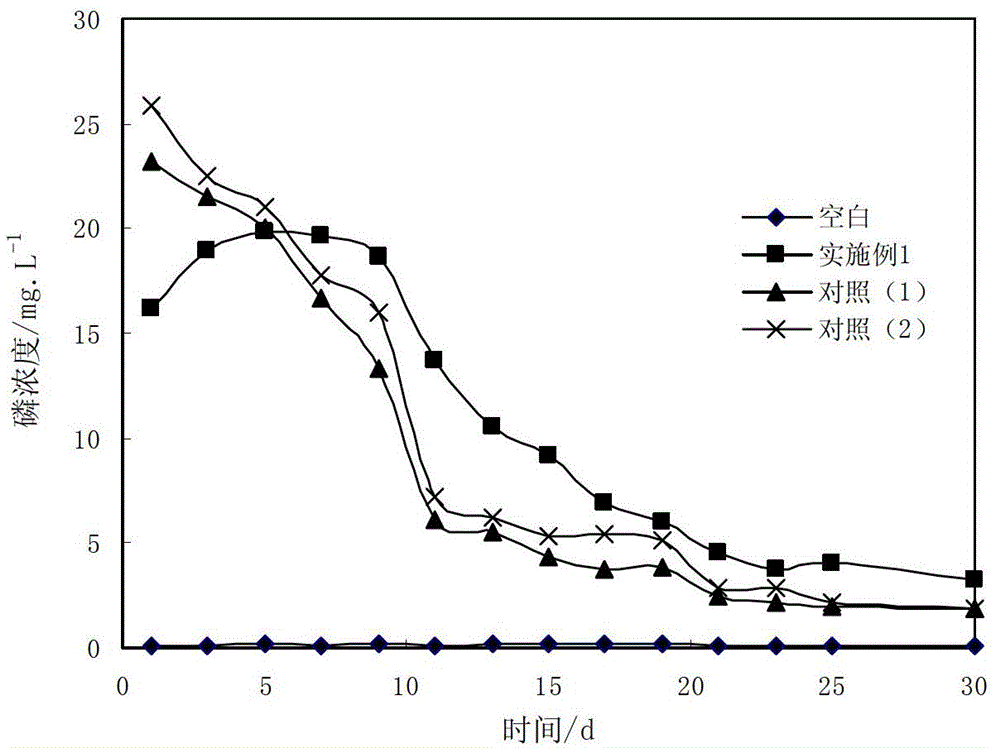

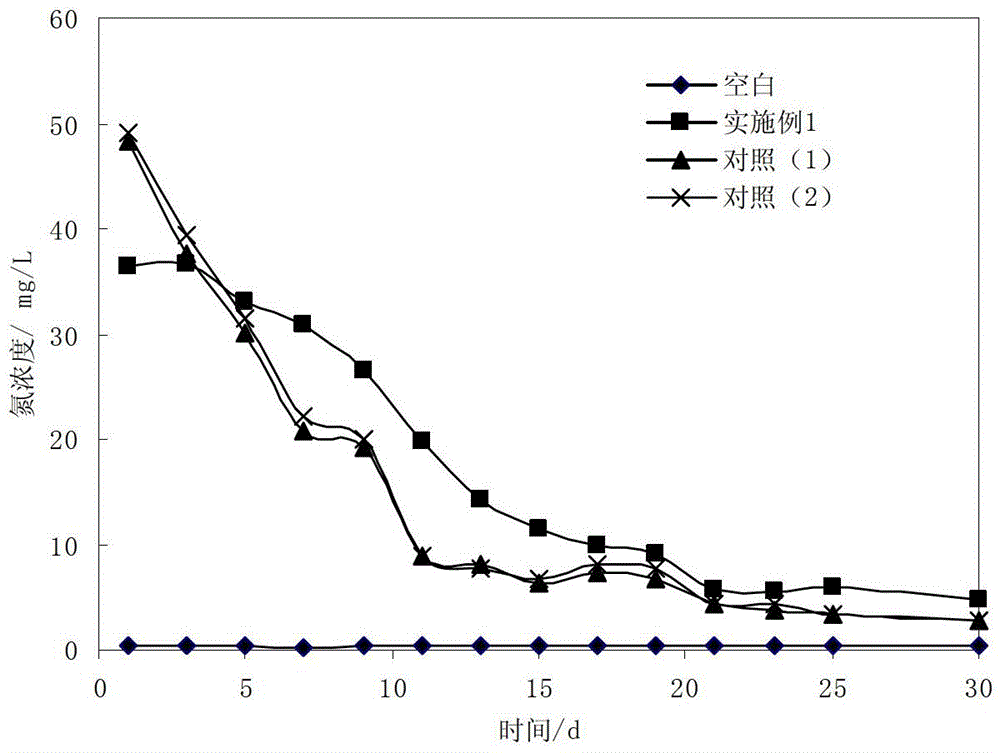

Embodiment 1

[0052] In this embodiment, the formula of red mud-based nitrogen and phosphorus slow-release granules is as follows:

[0053] 50g of alkaline red mud base material, 5g of hemihydrate gypsum, 3g of modified starch, 40g of mixed nitrogen and phosphorus fertilizer (potassium nitrate + potassium dihydrogen phosphate, the weight ratio of nitrogen and phosphorus is 1:0.6), 2g of agricultural waste (rice straw). The amount of water used is 45g.

[0054] The preparation method of the red mud-based nitrogen and phosphorus sustained and controlled release granules comprises the following steps:

[0055] (1) The alkaline red mud base material is ground by a pulverizer and passed through a 100-mesh sieve, and the agricultural waste is ground and passed through a 200-mesh sieve, and the ingredients are weighed according to the formula and set aside;

[0056] (2) Mix the red mud base material, hemihydrate gypsum and agricultural waste, spray the water agent dissolved with modified starch, th...

Embodiment 2

[0060] In this embodiment, the formula of red mud-based nitrogen and phosphorus slow-release granules is as follows:

[0061] 60g of alkaline red mud base material, 6g of hemihydrate gypsum, 4g of modified starch, 27g of mixed nitrogen and phosphorus fertilizer (potassium nitrate + dipotassium hydrogen phosphate, the weight ratio of nitrogen and phosphorus is 1:0.8), 3g of agricultural waste (crushed wheat husk). The water consumption is 50g.

[0062] The preparation method of the red mud-based nitrogen and phosphorus sustained and controlled release granules comprises the following steps:

[0063] (1) The alkaline red mud base material is ground by a pulverizer and passed through a 100-mesh sieve, and the agricultural waste is ground and passed through a 200-mesh sieve, and the ingredients are weighed according to the formula and set aside;

[0064] (2) Mix the red mud base material, hemihydrate gypsum and agricultural waste, spray the water agent dissolved with modified sta...

Embodiment 3

[0068] In this embodiment, the formula of red mud-based nitrogen and phosphorus slow-release granules is as follows:

[0069] 70g of alkaline red mud base material, 12g of construction gypsum, 5g of modified starch, 15g of mixed nitrogen and phosphorus fertilizer (calcium nitrate + superphosphate, nitrogen and phosphorus weight ratio is 1:1), 5g of agricultural waste (crushed rice husk). The amount of water used was 59g.

[0070] The preparation method of the red mud-based nitrogen and phosphorus sustained and controlled release granules comprises the following steps:

[0071] (1) The alkaline red mud base material is ground by a pulverizer and passed through a 100-mesh sieve, and the agricultural waste is ground and passed through a 200-mesh sieve, and the ingredients are weighed according to the formula and set aside;

[0072] (2) Mix the red mud base material, construction gypsum and agricultural waste, spray the water agent dissolved with modified starch, the water consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com