3D printer wire rod winding mechanism

A 3D printer and winding mechanism technology, applied in the field of wire materials, can solve problems such as easy to be polluted by the external environment, low reliability in use, and damage to hard materials, so as to improve the utilization rate of subsequent use, improve the reliability of use, and reduce reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail with reference to the following examples. It should be understood that the specific embodiments described here are only used to explain the invention and not to limit the invention.

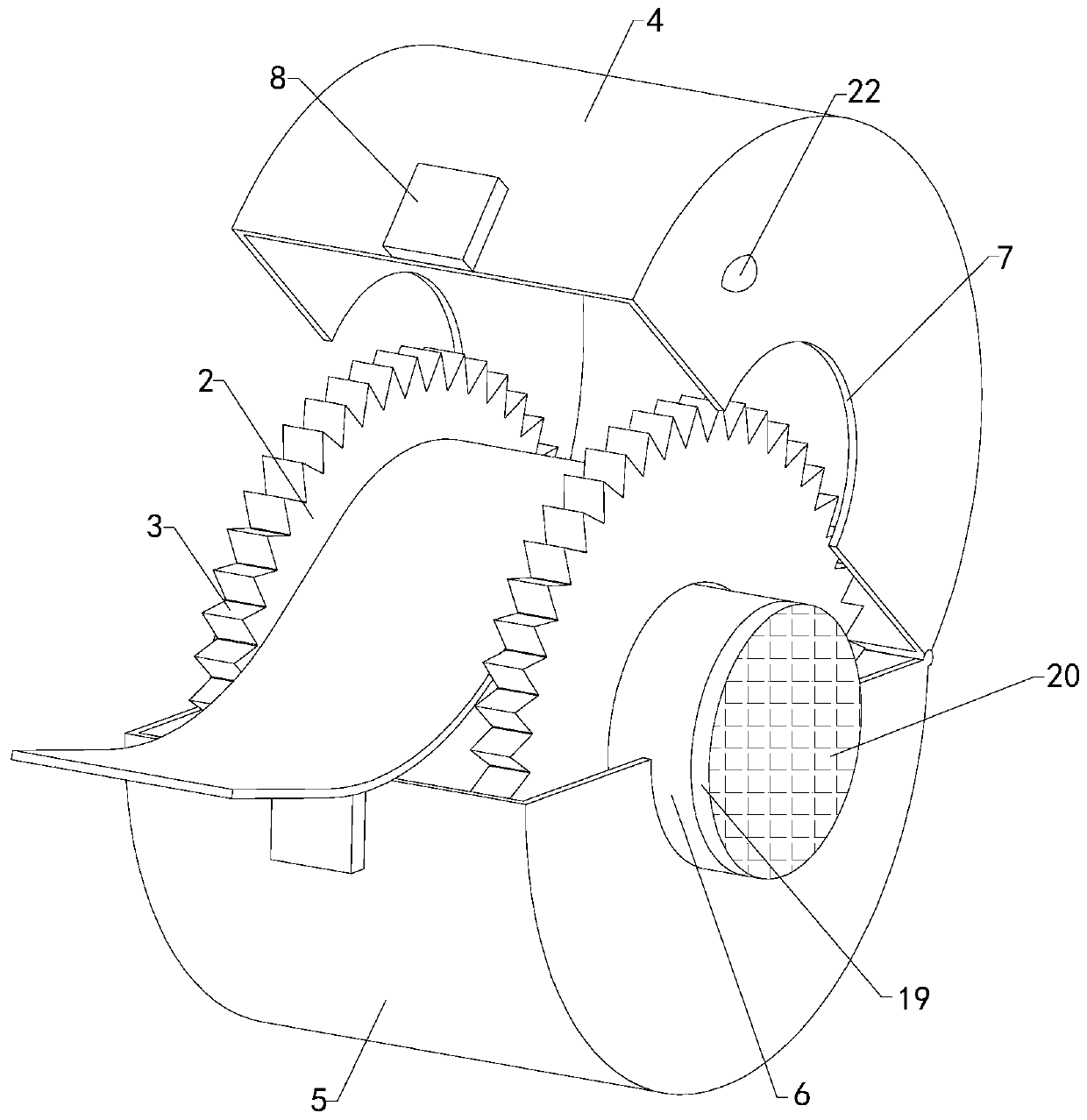

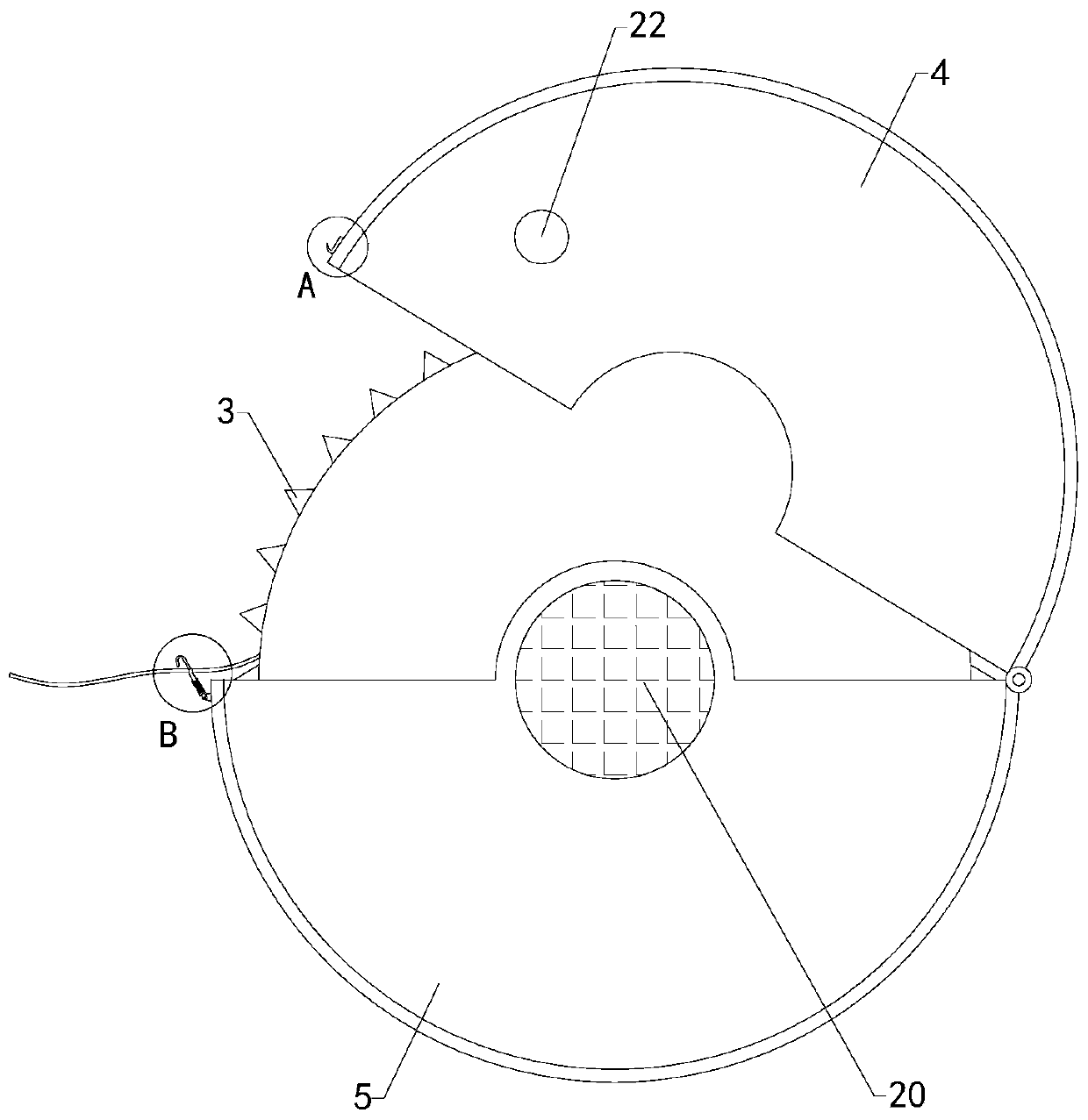

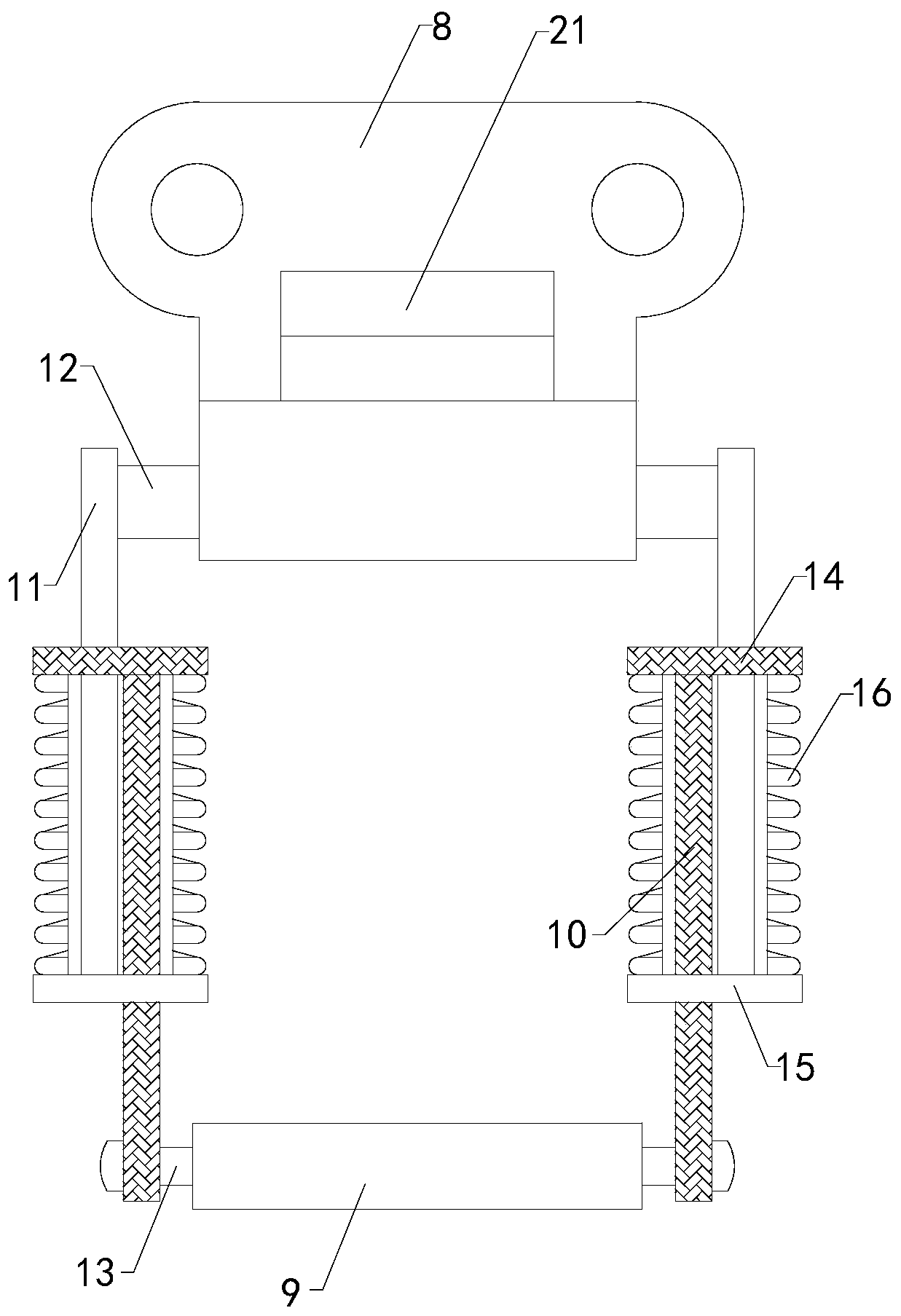

[0020] Reference Figure 1 to Figure 6 , A 3D printer wire winding mechanism of the present invention includes a core body 1, a through hole penetrating forward and backward is provided in the middle of the core body 1, and the outer front side and the rear side of the core body 1 are respectively fixedly sleeved with a left stop plate 2 and Right stop plate; The left stop plate 2 and the right stop plate have multiple sets of serrations 3 evenly arranged on the circumferential outer walls, and the tips of the multiple sets of serrations 3 diverge outward away from the central axis of the through hole; It includes an upper protective cover 4, a lower protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com