Aluminum alloy board, assembly and member for automobile using the aluminum board

A technology for aluminum alloy plates and aluminum alloy substrates, which is applied in the field of aluminum alloy plates, can solve the problems of reduced bonding strength, interface peeling, deterioration, peeling, etc., and achieves the effect of excellent bonding durability and difficult to reduce bonding strength

Inactive Publication Date: 2013-08-14

KOBE STEEL LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when exposed to a degraded environment such as a high temperature and humid environment in which moisture, oxygen, chloride ions, etc. permeate, copper as an alloy component concentrates on the surface where the oxide film is removed, and the deterioration of the adhesive layer is accelerated by the action of the copper. The phenomenon known as copper damage occurs

As a result, moisture or the like may permeate into the base (substrate) of the aluminum alloy plate, the interface may deteriorate, interface peeling may occur, and the bonding strength may decrease.

[0011] In addition, in the method of anodizing, in order to prevent the deterioration and peeling of the interface,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

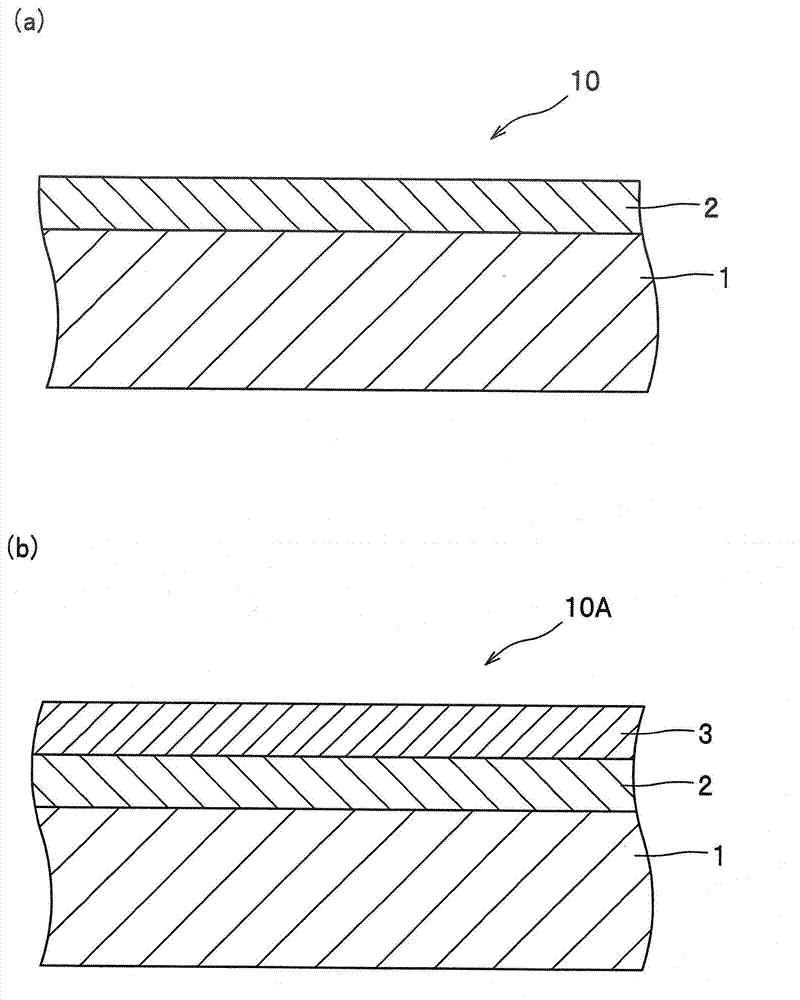

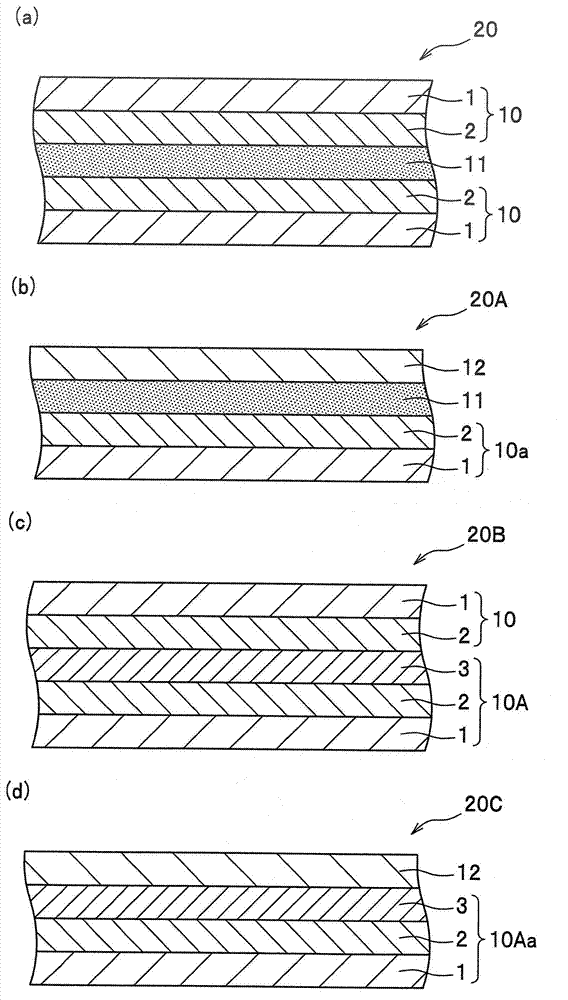

The present invention provides an aluminum alloy board that has a permanent sticking performance by which interfacial peeling of a bonding interface of an adhesive is hard to generate even under hot and wet environment, and the invention provides an assembly and a member for automobile using the aluminum board. The aluminum alloy board has an aluminum alloy baseplate (1),and a surface oxide film (2) formed on the surface of the aluminum alloy baseplate (1), wherein the aluminum alloy baseplate contains Mg and Cu, the ratio between Mg and Cu (Mg/Cu (weight percentage)) is under 50; the surface oxide film (2) contains Zr and Cu, and the ratio between Zr and Cu (Zr /Cu (atom percentage)) is above 0.02.

Description

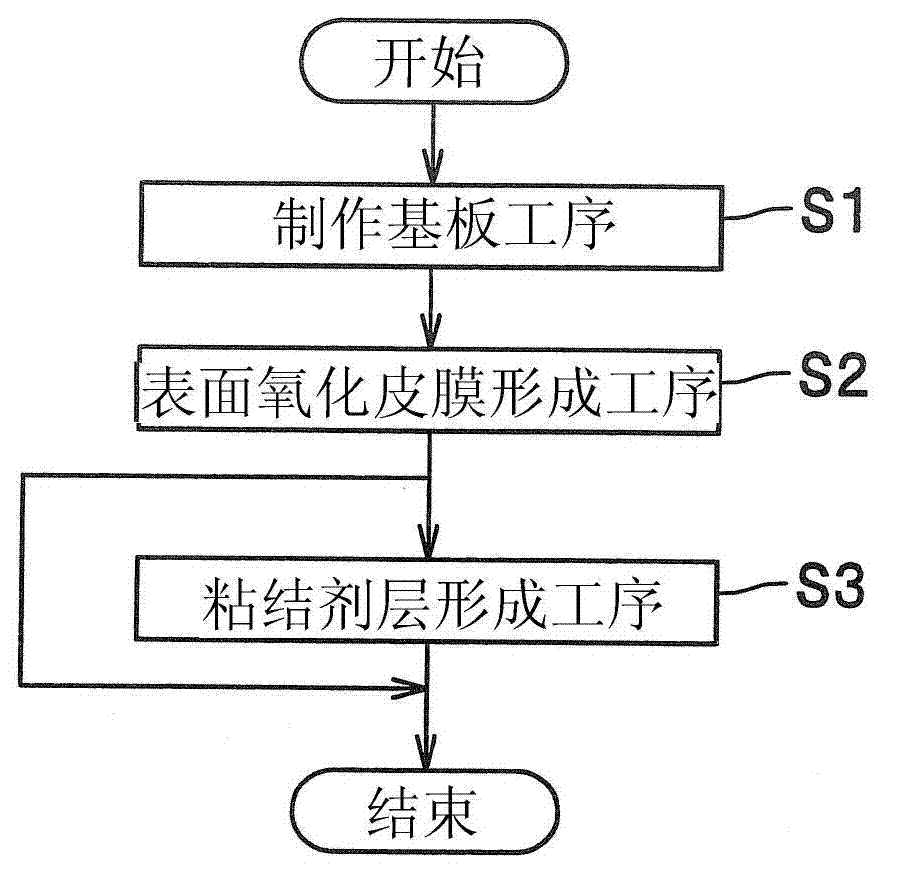

technical field [0001] The present invention relates to an aluminum alloy sheet for use in vehicles such as automobiles, ships, and airplanes, and in particular, an aluminum alloy sheet suitable for an automobile panel, a bonded body using the same, and an automobile member. Background technique [0002] Conventionally, various aluminum alloy sheets are commonly used as members of transportation machines such as automobiles, ships, and airplanes according to the characteristics of each alloy. Especially in recent years it has been realized that CO 2 Due to global environmental problems such as emissions, it is required to improve fuel efficiency by reducing the weight of components, and the specific gravity is about 1 / 3 that of iron, and the use of aluminum alloy plates with excellent energy absorption is increasing. [0003] For example, examples of aluminum alloy sheets used in automotive components include Mg-containing aluminum alloy sheets such as JIS 5000-series Al-Mg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/00B32B15/04B32B15/20C23C28/00C23C22/00

CPCC22C21/08C22C21/10C22C21/16C23C28/04

Inventor 高田悟巽明彦

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com