Copper-strengthened low-alloy high-strength steel for hot dip galvanizing

A hot-dip galvanizing, low-alloy technology, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problems of waste of Ti, Nb, unfavorable precipitation, etc., to reduce metallurgical costs and ensure high-strength steel. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

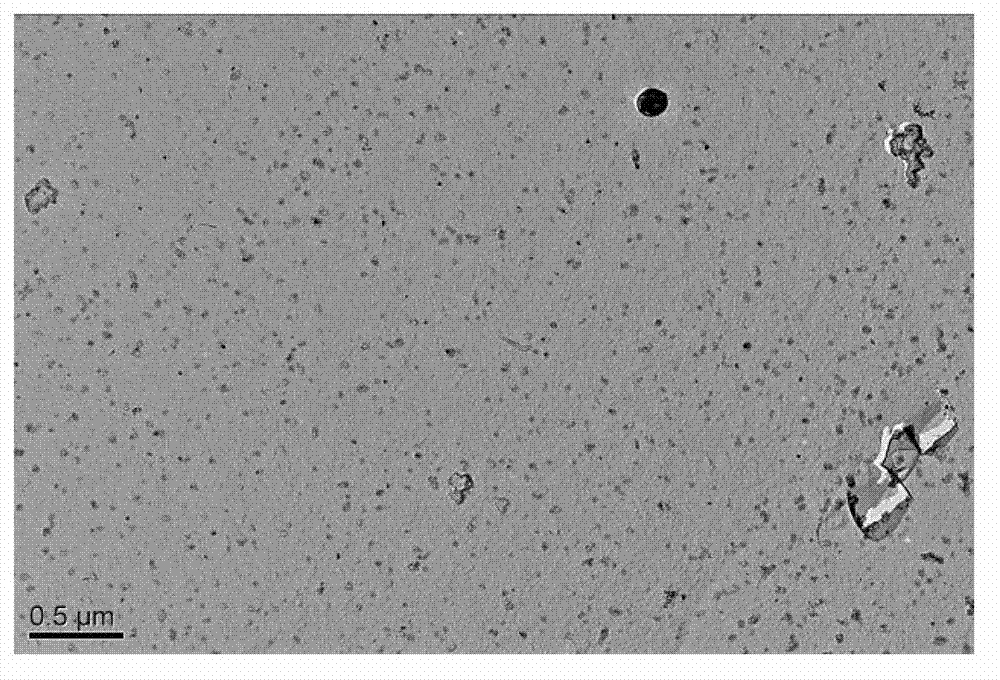

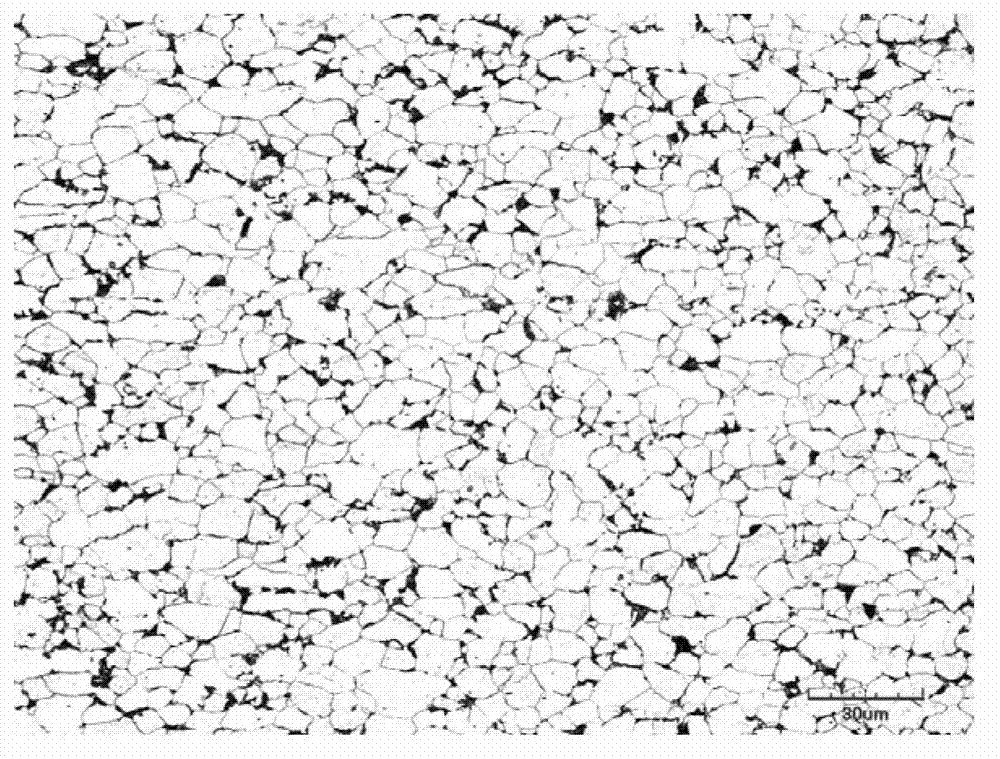

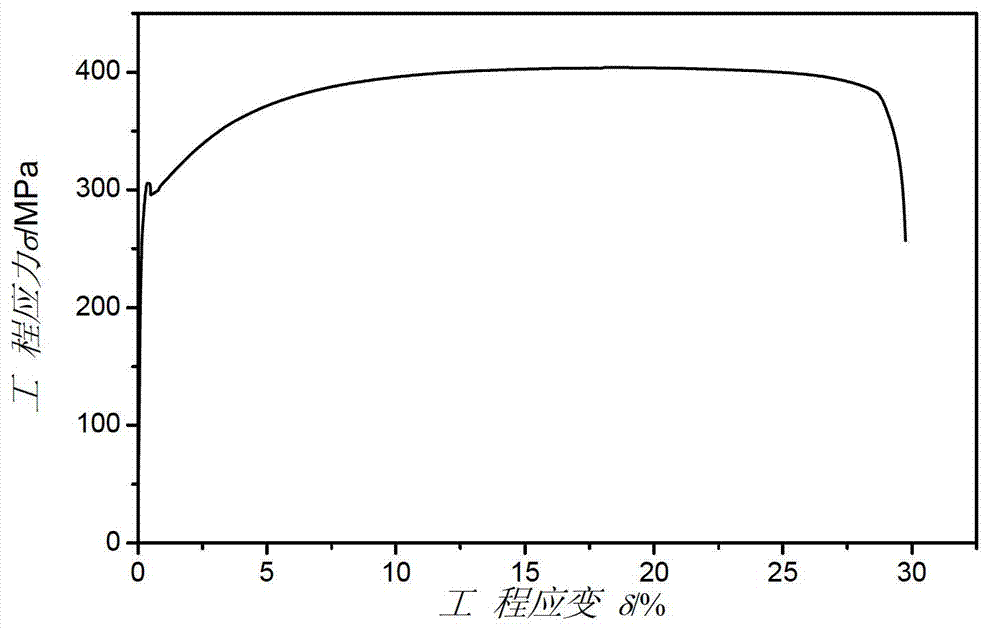

[0033] The chemical composition percentages of the copper-strengthened low-alloy high-strength steel for hot-dip galvanizing provided in this example are: C: 0.1%, Si: 0.01%, Mn: 0.45%, P: 0.01%, S: 0.008%, Cu: 0.02%, Alt: 0.053%, and the rest are Fe and trace alloy elements. The hot-dip galvanized high-strength steel produced with this chemical composition ratio contains fine Cu 2 S precipitates, such as figure 1 shown. The matrix metallographic structure is ferrite + cementite, such as figure 2 shown. The elongation after breaking reaches 30%, the yield strength reaches 300MPa, and the tensile strength reaches 400MPa. image 3 As shown, it meets the requirements for HX260LAD+Z in GT / T2518-2008.

Embodiment 2

[0035]The difference between this example and Example 1 is that the chemical composition percentages of the copper-strengthened low-alloy high-strength steel for hot-dip galvanizing provided in this example are: C: 0.11%, Si: 0.03%, Mn: 1.4% , P: 0.01%, S: 0.018%, Cu: 0.2%, Alt: 0.065%, and the rest are Fe and trace alloy elements. Its elongation reaches 20%, the yield strength reaches 440MPa, and the tensile strength reaches 500MPa, meeting the requirements for HX420LAD+Z in GT / T2518-2008. Other places are completely consistent with embodiment 1.

Embodiment 3

[0037] The difference between this example and Example 1 is that the chemical composition percentages of the copper-strengthened low-alloy high-strength steel for hot-dip galvanizing provided in this example are: C: 0.04%, Si: 0.02%, Mn: 0.6% , P: 0.02%, S: 0.01%, Cu: 0.1%, Alt: 0.053%, and the rest are Fe and trace alloy elements. Its elongation reaches 25%, the yield strength reaches 330MPa, and the tensile strength reaches 430MPa, meeting the requirements for HX300LAD+Z in GT / T2518-2008. Other places are completely consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com