Application of foamed light soil in repairing of building foundation subsidence holes

A foam lightweight soil, foundation subsidence technology, applied in the direction of construction, infrastructure repair, infrastructure engineering, etc. The effect of firm rate and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

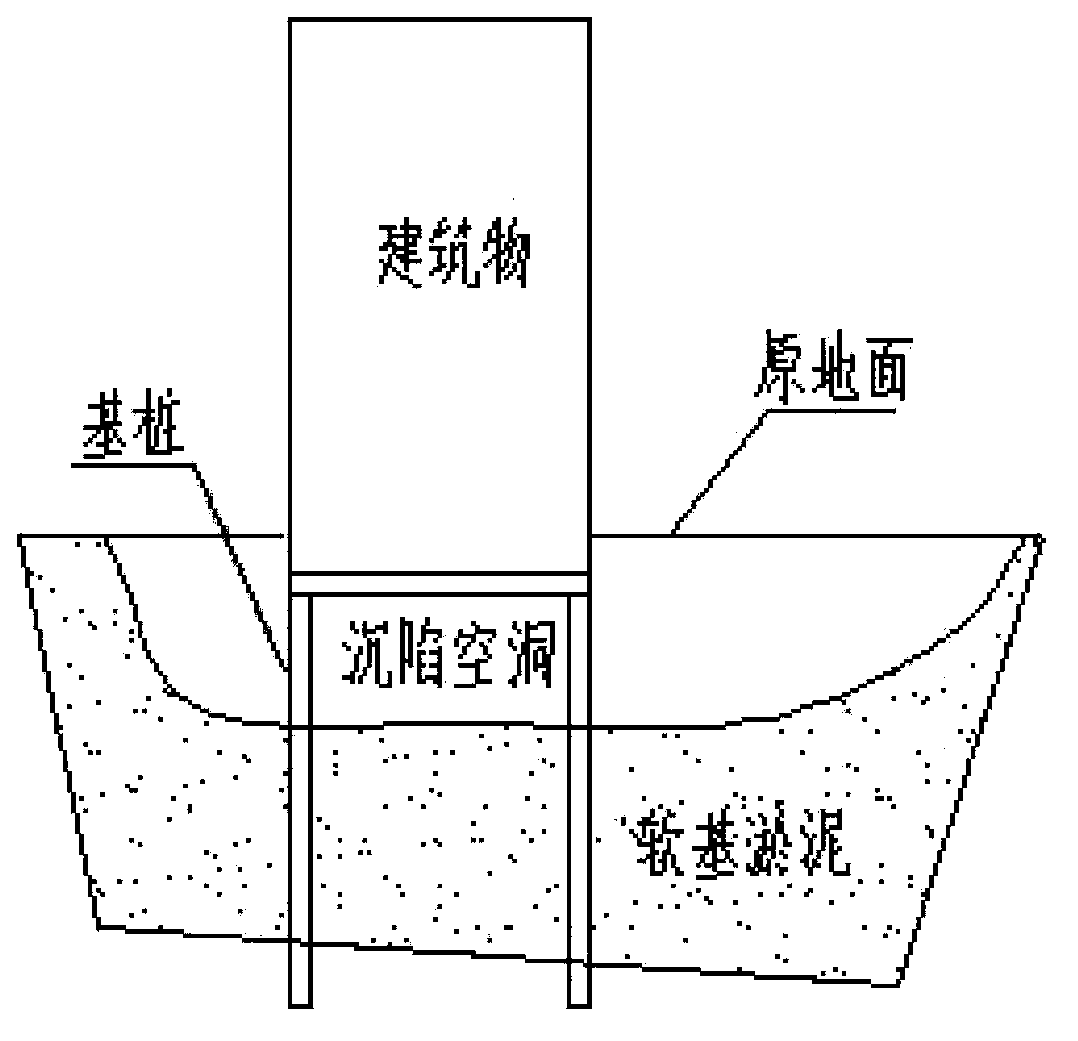

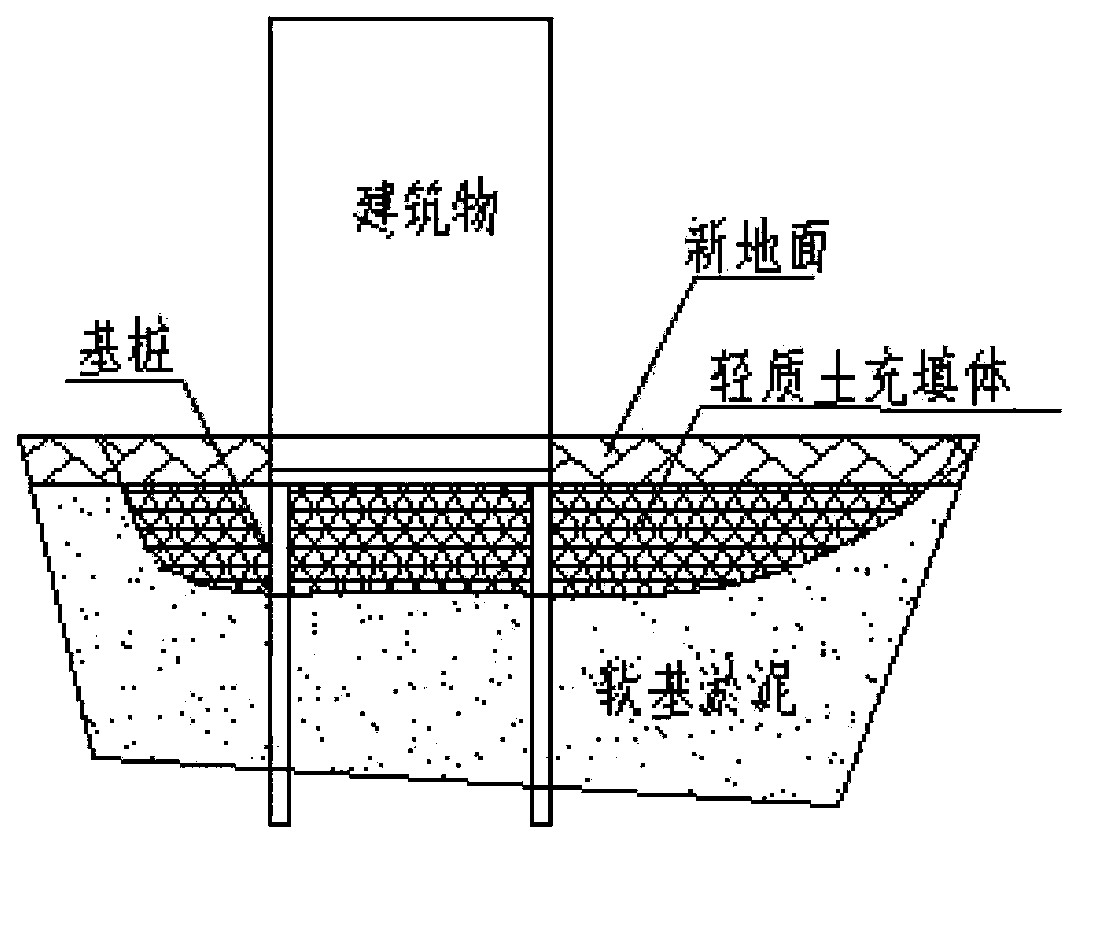

[0020] A subsidence cavity in the foundation of a building, its structure is as follows figure 1 As shown, the building above the cavity is 30 meters high, and the subsidence cavity is about 2 meters deep when it is processed. The subsidence cavity of the foundation of the building is repaired by using foam light soil, including the following steps:

[0021] (1) According to the height of the building above the subsidence cavity, the density of the foam light soil to be used is determined to be 580 kg / m 3 , the strength is 0.8MPa;

[0022] (2) When starting the treatment, dig out the soft silt in the subsidence cavity, and then lay a waterproof geomembrane on the bottom layer of the subsidence cavity (purchased from Dezhou Dongfang Geotechnical Materials Co., Ltd., specification 0.5-1.0mm; the same below);

[0023] (3) Prepare foam light soil with the required density and strength at the construction site, and pour it into the subsidence cavity of the building foundation; wh...

Embodiment 2

[0027] A subsidence cavity in the foundation of a building, its structure is as follows figure 1 As shown, the building above the cavity is 60 meters high, and the subsidence cavity is about 3 meters deep when it is processed. The subsidence cavity of the foundation of the building is repaired by using foam light soil, including the following steps:

[0028] (1) According to the height of the building above the subsidence cavity, the density of the foam lightweight soil to be used is determined to be 650 kg / m 3 , the strength is 1.0MPa;

[0029] (2) When starting the treatment, dig out the soft silt in the subsidence cavity, and then lay a waterproof geomembrane on the bottom layer of the subsidence cavity;

[0030] (3) Prepare foam light soil with the required density and strength at the construction site, and pour it into the subsidence cavity of the building foundation; when pouring, pour it in layers, with a thickness of 80cm for each layer; pour the latter layer before ...

Embodiment 3

[0034] A subsidence cavity in the foundation of a building, its structure is as follows figure 1 As shown, the building above the cavity is 15 meters high, and the subsidence cavity is about 1.5 meters deep when it is processed. The subsidence cavity of the foundation of the building is repaired by using foam light soil, including the following steps:

[0035] (1) According to the height of the building above the subsidence cavity, the density of the foam lightweight soil to be used is determined to be 550 kg / m 3 , the strength is 0.6MPa;

[0036] (2) When starting the treatment, dig out the soft silt in the subsidence cavity to make the cavity reach a depth of 2 meters, and then lay a waterproof geomembrane on the bottom layer of the subsidence cavity;

[0037] (3) Prepare foam light soil with the required density and strength at the construction site, and pour it into the subsidence cavity of the building foundation; when pouring, pour it in layers, with a thickness of 50c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com