Anti-glare suspended ceiling and production method thereof

An anti-glare and anti-glare film technology, applied in the direction of ceilings, building components, buildings, etc., can solve the problems of affecting eyesight, affecting indoor lighting effects, and no anti-glare, and achieve the effect of good anti-glare function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0015] An anti-glare suspended ceiling includes a core layer and surface layers arranged on the upper and lower surfaces of the core layer, the core layer is a cement gel layer, and the surface layer is an anti-glare film layer.

[0016] The anti-glare film layer includes polycarbonate and anti-glare absorber, and the ratio of polycarbonate and anti-glare absorber is 100:0.5.

[0017] The anti-glare absorber is IR530, IR580 or IR1060.

[0018] The cement gel layer includes magnesium oxide, cotton fiber, wood chips, talcum powder and water.

[0019] The parts by weight of magnesium oxide, cotton fiber, wood chips, talcum powder and water contained in the cement gel layer are 40-50 parts of magnesium oxide; 5-10 parts of cotton fiber; 5-10 parts of wood chips; 5 parts; 10-20 parts of water.

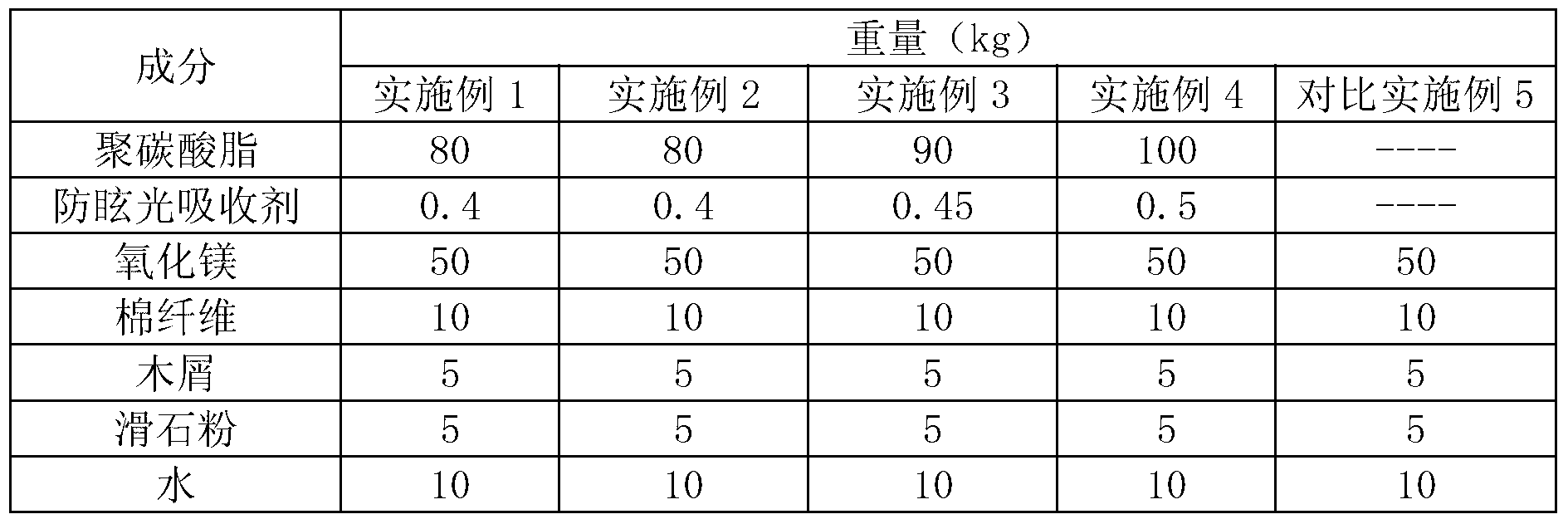

[0020] Table 1 is the weight of each component of Examples 1-4.

[0021]

[0022] The weight of each composition of table 1 embodiment 1-4

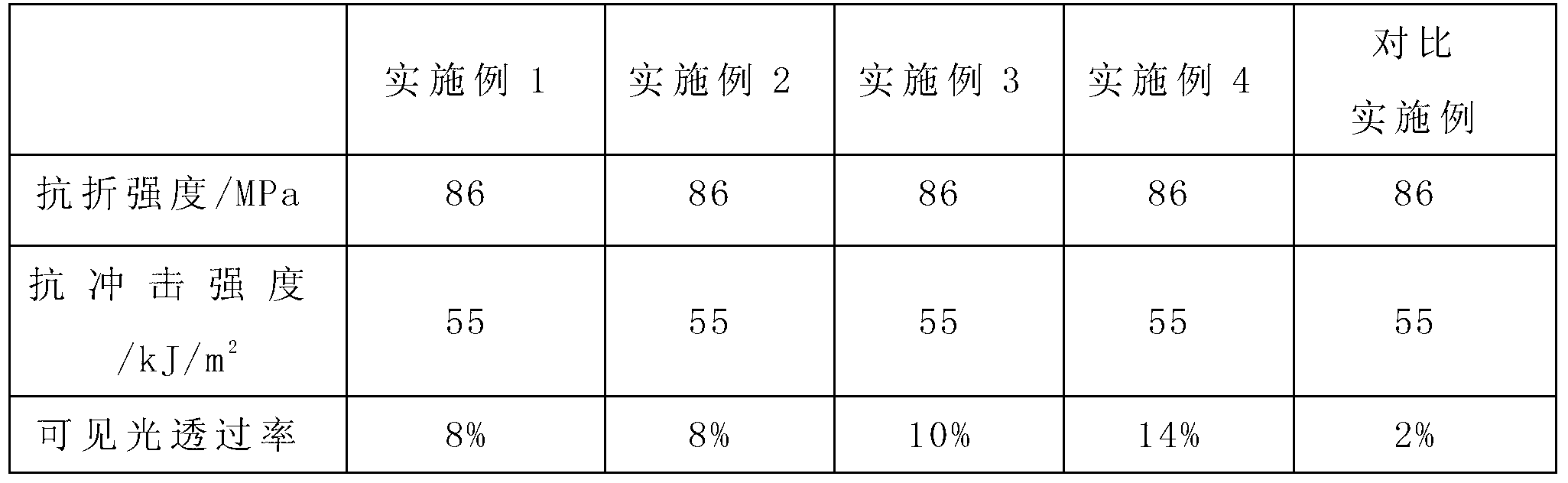

[0023] Make a kind of anti-glare suspende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com