A kind of preparation method of anti-glare glass

An anti-glare and glass technology, used in optomechanical equipment, microlithography exposure equipment, originals for optomechanical processing, etc. Good anti-glare function, best light transmittance and gloss, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

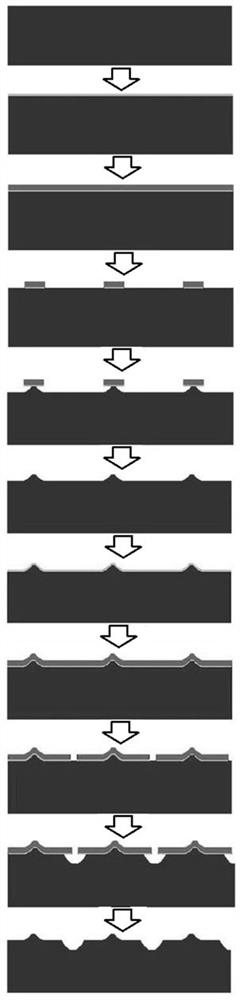

[0038]A preparation method of anti-glare glass, comprising the steps of:

[0039] S1, forming a patterned first photoresist layer on the structural surface of the cleaned glass substrate;

[0040] S2. Using the patterned first photoresist layer as a mask, etch the glass substrate to a given depth by first wet etching;

[0041] S3, cleaning the etched glass substrate, removing the first photoresist layer, and obtaining a glass substrate with a convex array on the structural surface;

[0042] S4. Clean the glass substrate obtained in step S3 again, and then form a patterned second pattern on the structural surface of the glass substrate by aligning the cross mark on the mask plate with the cross mark formed by the first wet etching of the glass substrate. photoresist layer;

[0043] S5. Using the patterned second photoresist layer as a mask, perform a second wet etching on the glass substrate to form an array of grooves (pits) on the structural surface of the glass substrate; ...

Embodiment 1

[0059] Raw material preparation:

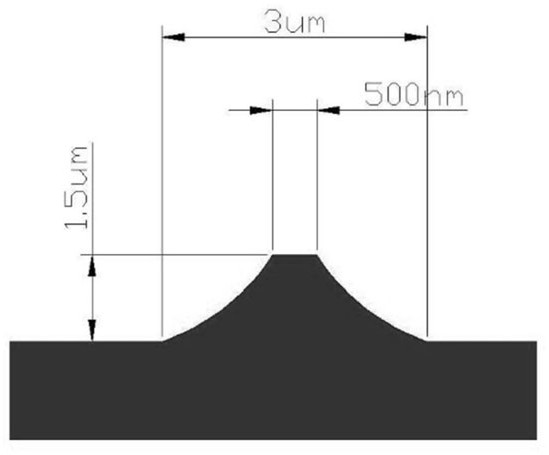

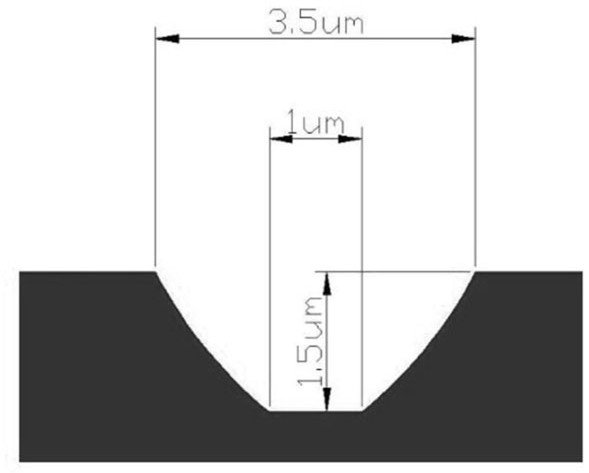

[0060] Make two masks, the 1# mask plate is a light-transmitting material plate, and a patterned structure is constructed on the light-transmitting material plate. The patterned structure is an array of chromium circles. The diameter of the chromium circles is 3 μm, and the distance between adjacent chromium circles is 12 μm. The 2# mask plate is a chromium mask plate, and a patterned light-transmitting structure is constructed on the chromium mask plate. The light-transmitting structure is an array of round holes, the diameter of the array round holes is 1 μm, and the distance between adjacent round holes is 12 μm.

[0061] Make cross alignment marks on the two mask boards respectively, and make a hollow cross in the middle of the square chromium block with alignment marks of 100μm×100μm. Make one in the middle of the left side and the right side, and make two mask alignment marks at the same position on the mask, so that when the 1# mask is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com