Processing method of anti-dazzling sheet glass

A processing method and anti-glare technology, applied in the coating and other directions, can solve the problems of easy cracking, weak mechanical resistance, dazzling human eyes, etc., and achieve the effect of improving impact resistance, good function and reducing gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

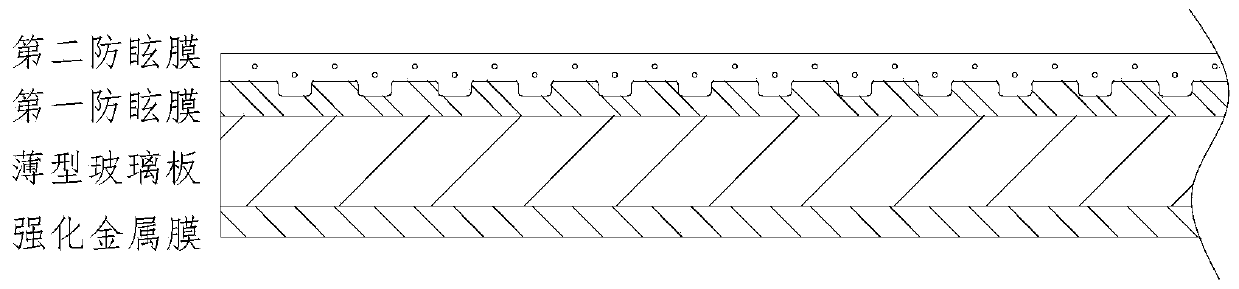

[0027] refer to figure 1 , figure 2 .

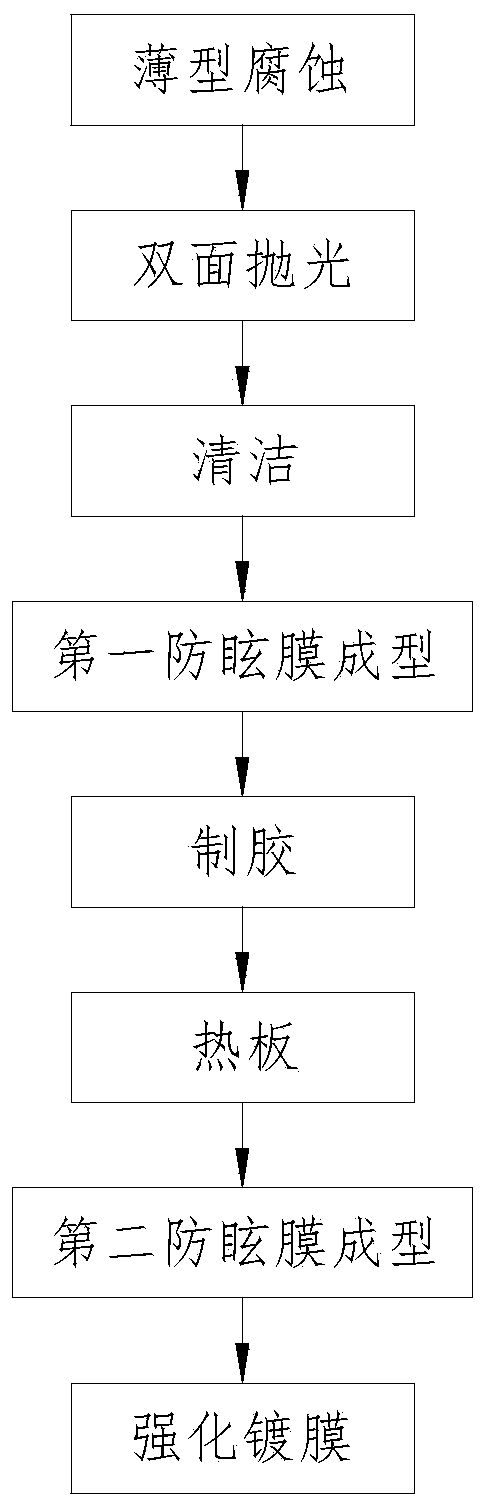

[0028] The embodiment of the present invention discloses a processing method of anti-glare thin plate glass, such as figure 1 As shown, the following steps are included in sequence:

[0029] S1. Thin etching: first cut the glass plate to obtain the required size and shape, and then put the glass plate into the etching solution to etch to obtain thin glass, and the thickness of the thin glass is uniform;

[0030] S2. Double-sided polishing: Polish the two surfaces of the thin glass with a polishing machine to obtain polished glass;

[0031] S3. Cleaning: cleaning the polished glass and obtaining clean glass after drying;

[0032] S4. Forming of the first ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com