Method for rush-repairing electric power circuit pole in paddy field and specialized pole foundation base

A technology for the foundation of power lines and poles, applied in towers, building types, buildings, etc., can solve the problems of windproof cable pulling, high fall accident of falling pole, secondary pole falling, etc., to achieve easy assembly, fast repair, strong foundation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

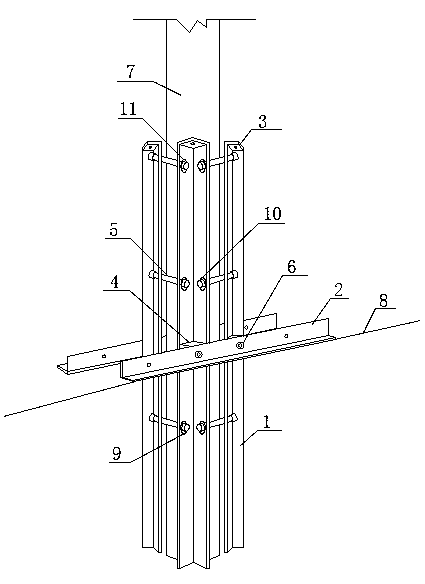

[0030] ①Put the inner corners of the four long angle steels outwards on the surroundings of the wooden pole respectively. The long angle steels should be as close as possible to the wooden pole. The short angle steel supported on the ground forms a 90-degree angle with the wooden pole. In order to prevent the direction of the base of the pole foundation from being inaccurate when it is drilled into the ground, install nails in the A holes of the four long angle steels, but not too tight, otherwise it will cause drilling into the ground. Difficulty on the ground;

[0031] ②Put nails on the B holes of the four long angle steels, and be careful not to fix them too tightly, otherwise it will be difficult to drill into the ground;

[0032] ③Put nails on the C holes of the four long angle steels, and be careful not to fix them too tightly, otherwise it will be difficult for the hammer to drill into the ground;

[0033] ④ The short angle steel used as the ground support is 90 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com