Method and device for testing flow conductivity of fracture network of shale

A technology of fracture network and flow conductivity, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., to achieve the effect of simple operation, economical and environmental protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

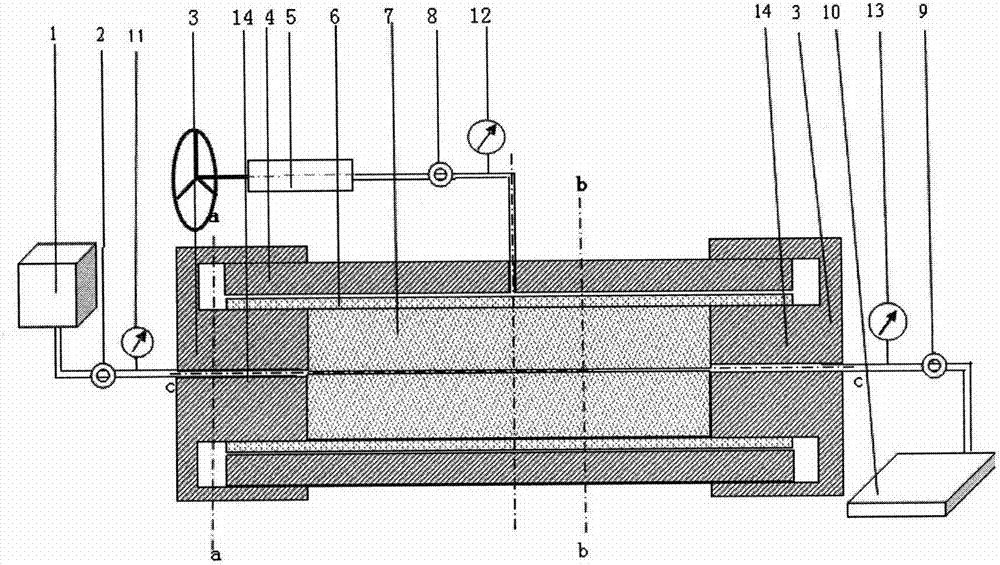

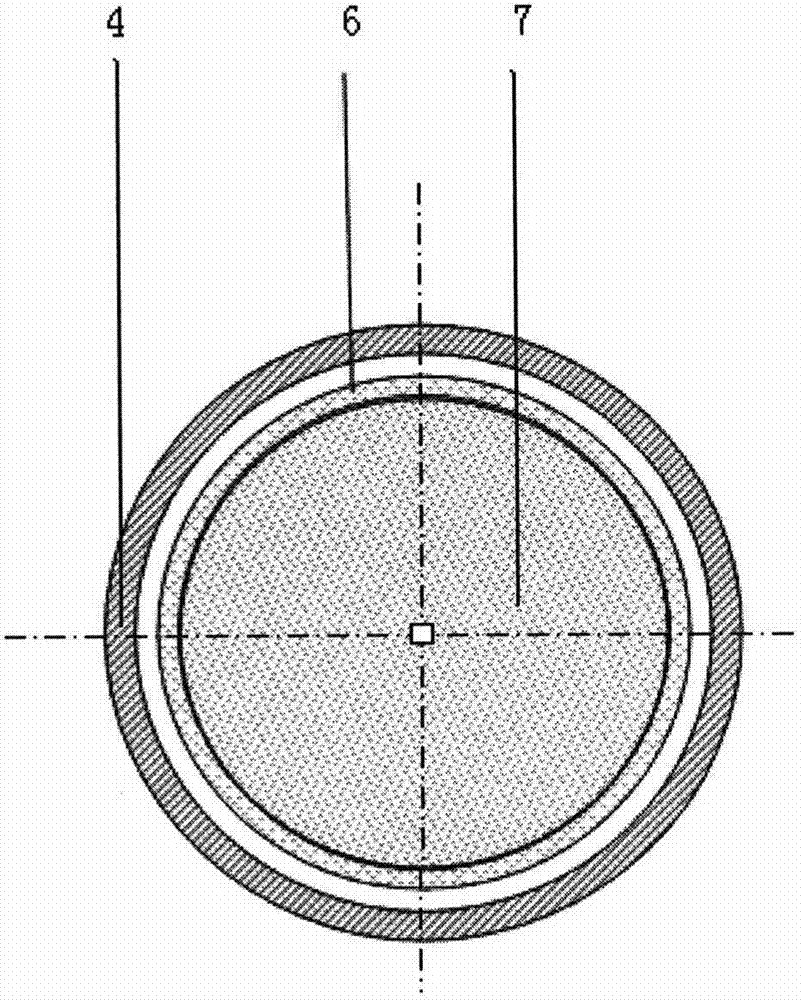

[0029] 1. Use the main components of the shale to be tested to make a semicircular model with a groove in the middle, and align and compress the two semicircular models to form a shale fracture network model 7 with a fracture network in the middle.

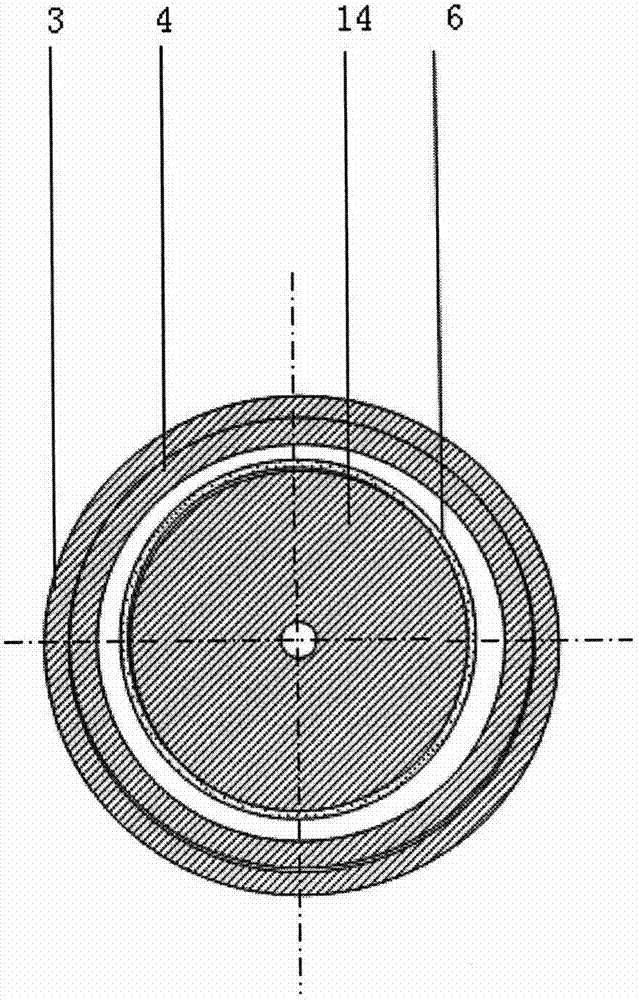

[0030] 2. Select the models of the annular sleeve 6 and the diversion chamber according to the size of the network model. Connect the selected diversion outer cylinder 4 with the ring pressure device 5 .

[0031] 3. Slowly push the shale fracture network model into the annular sleeve 6, then push the annular sleeve and the shale fracture network model 7 into the diversion chamber 4, and add a cover 3 at both ends of the diversion chamber to make the seal The cover inside projection 14 is inside the annular sleeve 6 and tightens the cover 3 .

[0032] 4. Open the ring pressure liquid supply valve 8, apply the ring pressure to the diversion chamber with the hand pump 5, and record the ring pressure with the ring pressure manometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com