Sun gear axial fixed structure

A sun gear shaft and fixed structure technology, applied in the direction of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of gearbox damage, poor reliability, and failure, and achieve no need to control torque, reliable anti-loosening, and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

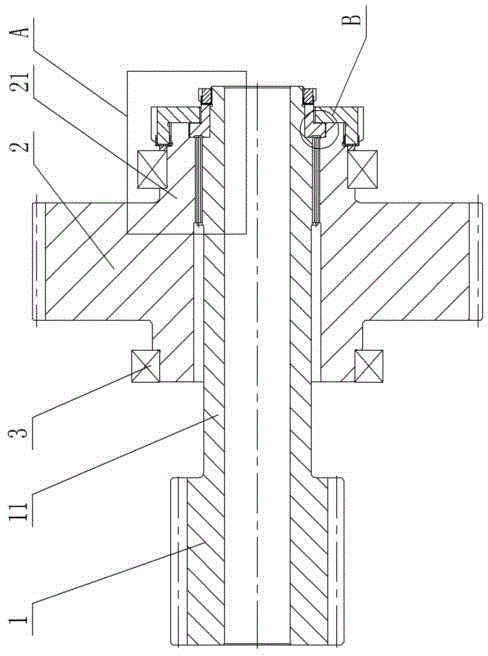

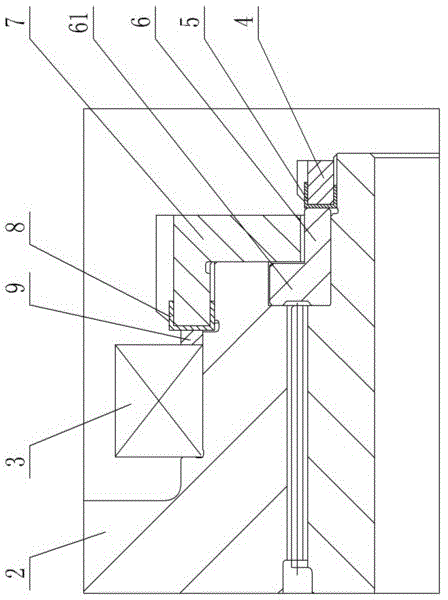

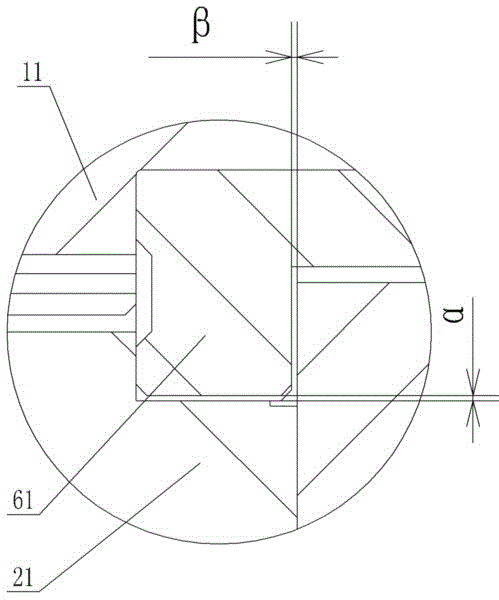

[0016] Such as Figure 1~Figure 3 As shown, 1. sun gear, 11. sun gear shaft, 2. bull gear, 21. bull gear shaft, 3. bearing, 4. inner lock nut, 5. inner stop washer, 6. positioning ring, 61. Flange, 7. Outer lock nut, 8. Outer stop washer, 9. Stop ring.

[0017] The axial fixed structure of the sun gear, such as figure 1 As shown, it mainly refers to the axial fixed structure between the sun gear 1 of the previous stage and the large gear 2 or planet carrier of the latter stage. It is especially suitable for various planetary gearboxes with harsh working conditions, large load fluctuations, large impacts or high reliability requirements, such as wind power gearboxes.

[0018] The sun gear 1 is provided with a sun gear shaft 11 extending to the right, and the sun gear shaft at the right end is the tail of the sun gear 1; the sun gear shaft 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com