Sealing ring with inner screw thread

An internal thread and sealing ring technology, applied to the field of internal thread carbide accessories, can solve the problems of lining following rotation, lining falling off, unstable use effect, etc., so as to prevent the following rotation phenomenon, ensure normal work, and have a reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

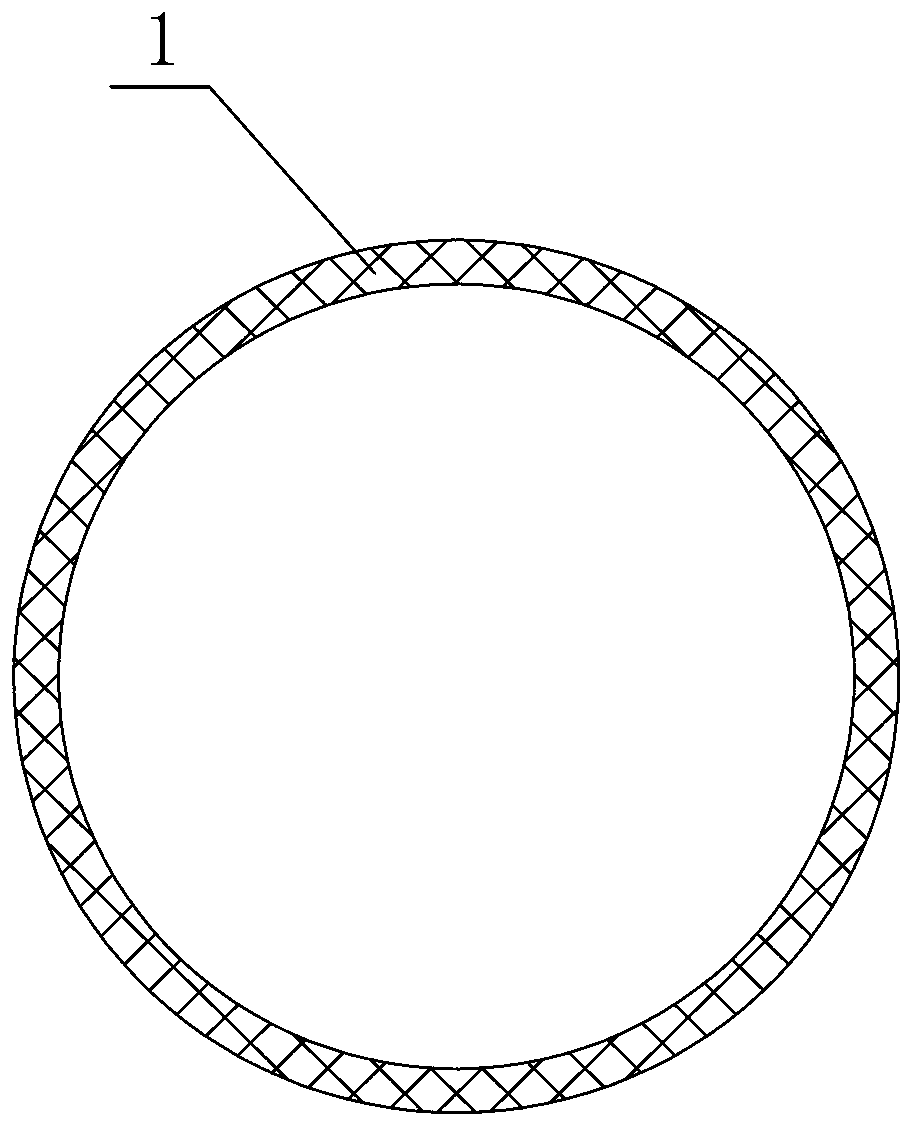

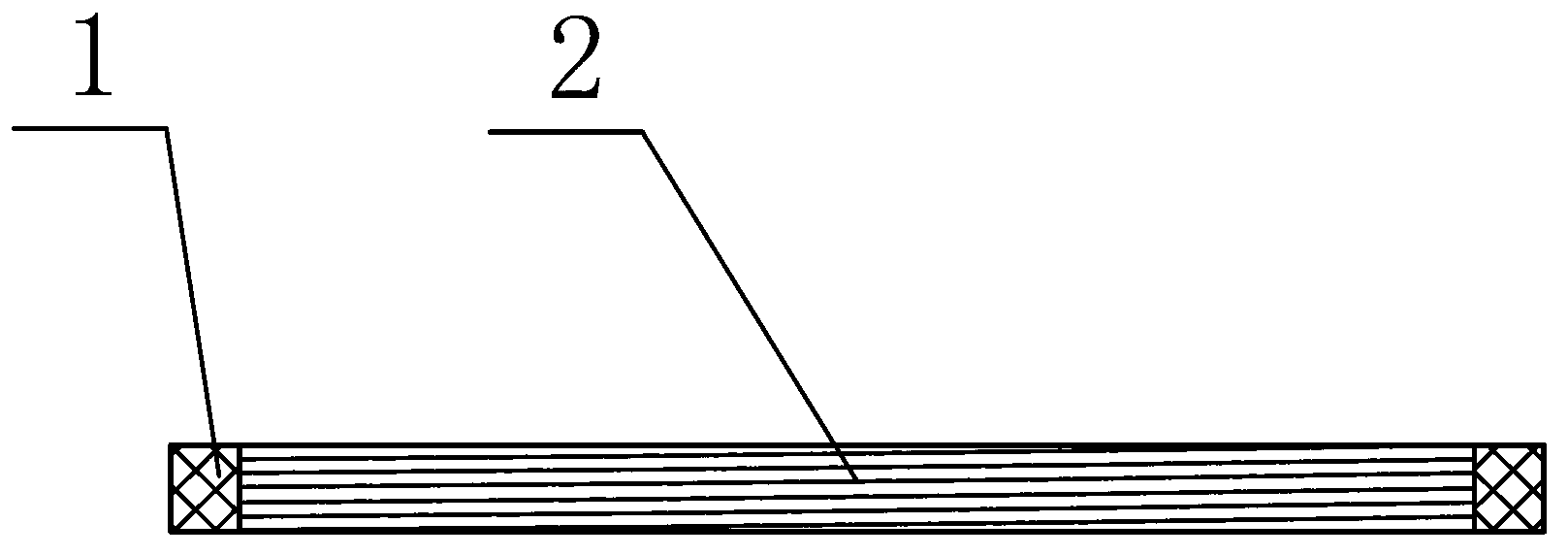

[0020] Such as figure 1 , figure 2 As shown, an internal thread sealing ring includes a fitting body, the fitting body is a fitting body made of an alloy material, and the width of the fitting body is 60-80 mm; all or part of the inner surface of the fitting body is provided with threads.

[0021] In this embodiment, the fitting body is a sealing ring body made of alloy material, and all inner surfaces of the fitting body are provided with threads. The width of the accessory body is 6mm. The thickness of the accessory body is 1-5mm. The thickness of the accessory body is 3mm.

[0022] In addition, there is another case where the accessory body 1 is made of tungsten alloy material, with a thickness of 1-4mm and a width of 1-7mm.

[0023] In actual use, the best material for the accessory body 1 is a sealing ring body made of tungsten carbide alloy material, with a thickness of 2mm and a width of 1-7mm. The best choice for the width of the accessory body is 4mm.

[0024] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com