LED (Light Emitting Diode) lamp with multiple heat dissipation structures

A technology for LED lamps and multiple heat dissipation, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve problems such as poor air circulation, narrow heat dissipation space, and high cost of lamps , to achieve the effect of fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

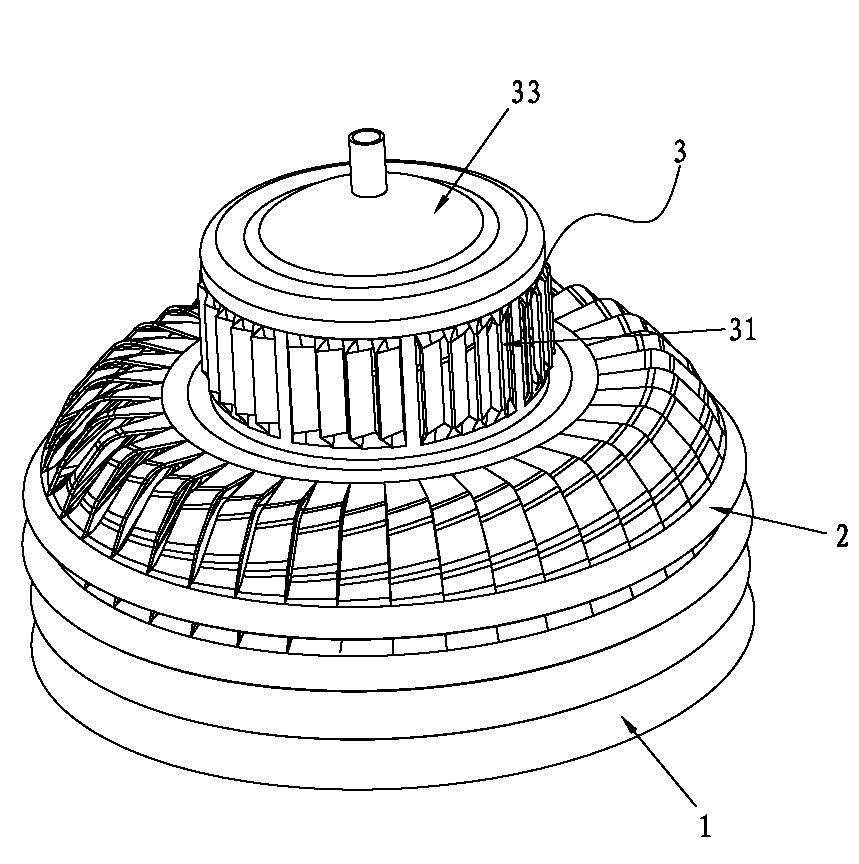

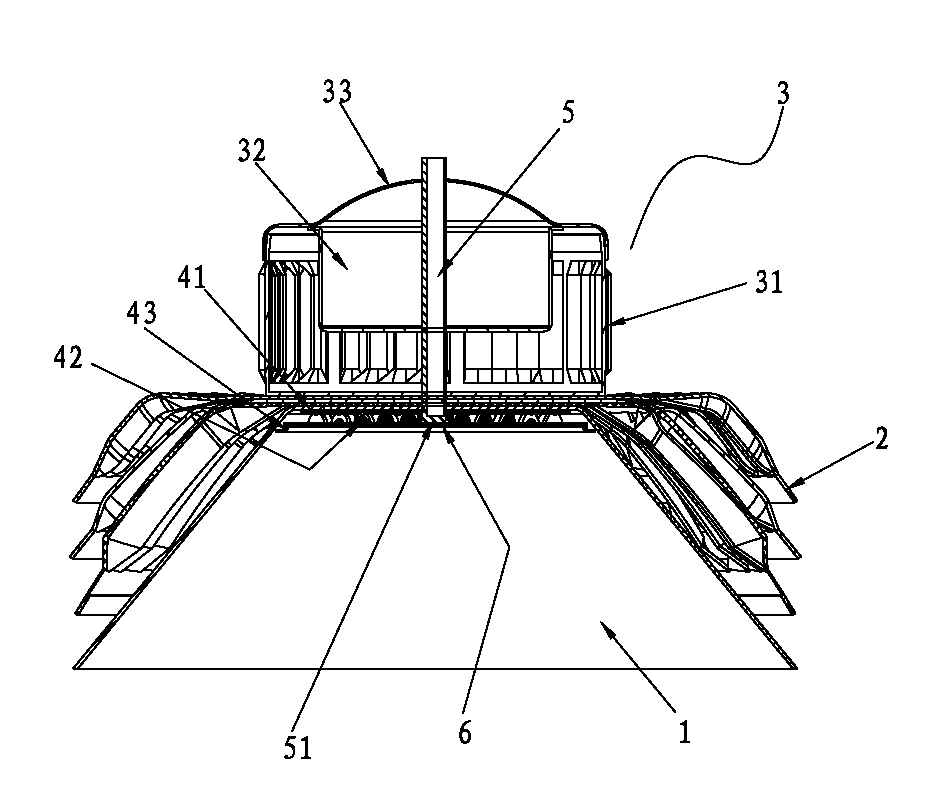

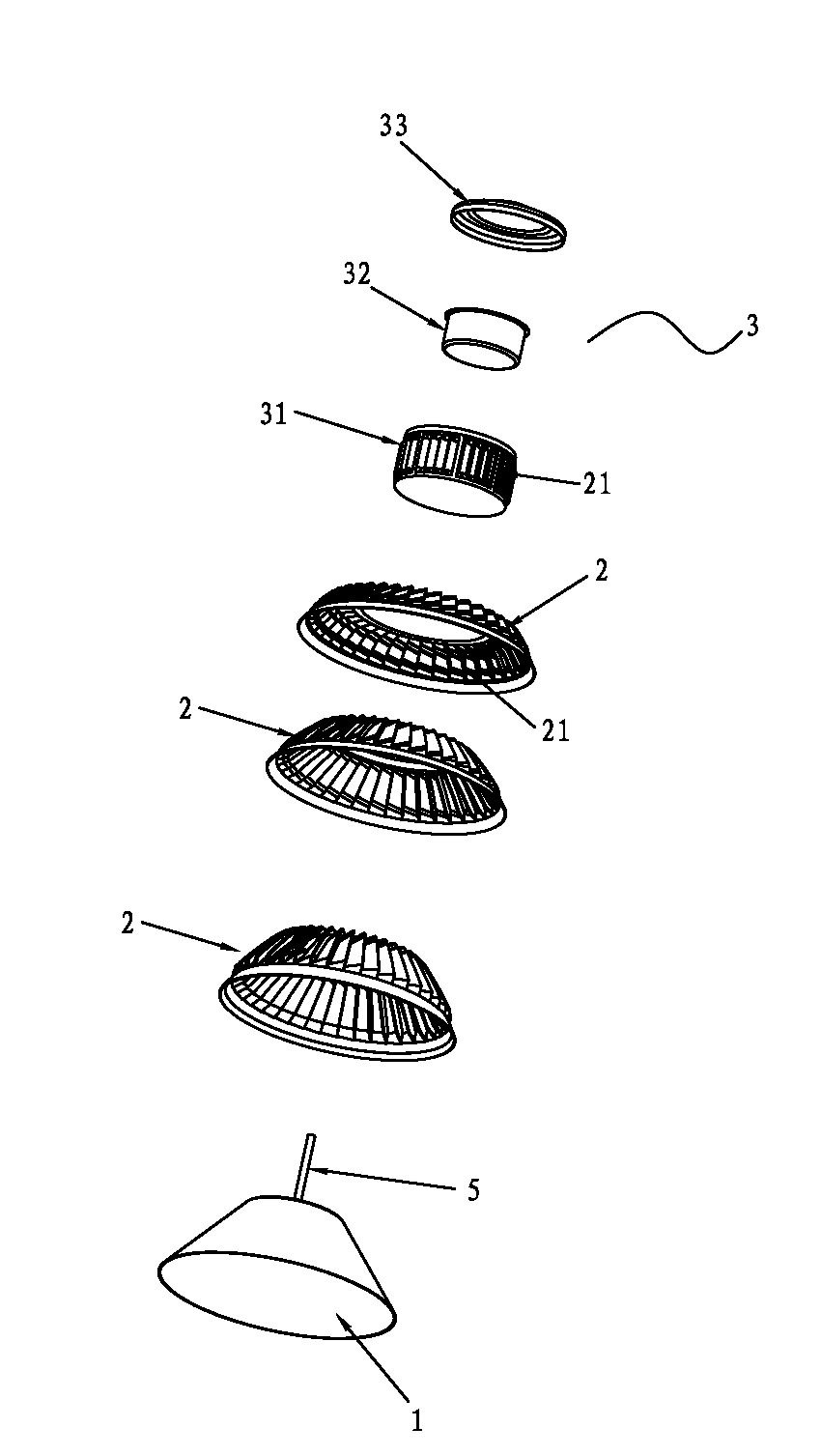

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an LED lamp with multiple heat dissipation structures includes a lampshade 1, an LED lighting assembly, a cylindrical heat dissipation cover 2 with a lower opening, an LED power supply and a power supply box 3; the circumferential wall of the heat dissipation cover 2 has The heat dissipation guide hole 21; the LDE light-emitting component includes an aluminum substrate 41, an LED lamp bead 42 and a lens 43, the aluminum substrate 41 is fixed on the top plate of the lampshade 1, and the top plate of the heat dissipation cover 2 is bonded to the top plate of the lampshade 1; the heat dissipation cover There is a gap between the circumferential wall of 2 and the circumferential wall of lampshade 1,

[0024] The direction of the heat dissipation guide hole on the heat dissipation cover 2 is left-hande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com