Light-emitting diode (LED) bulb with internal convection radiating structure and LED light source device

A technology for LED light bulbs and light bulbs, applied in lighting and heating equipment, light sources, point light sources, etc., can solve the problems of unstable light bulb performance, low production efficiency, and complex production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and embodiments.

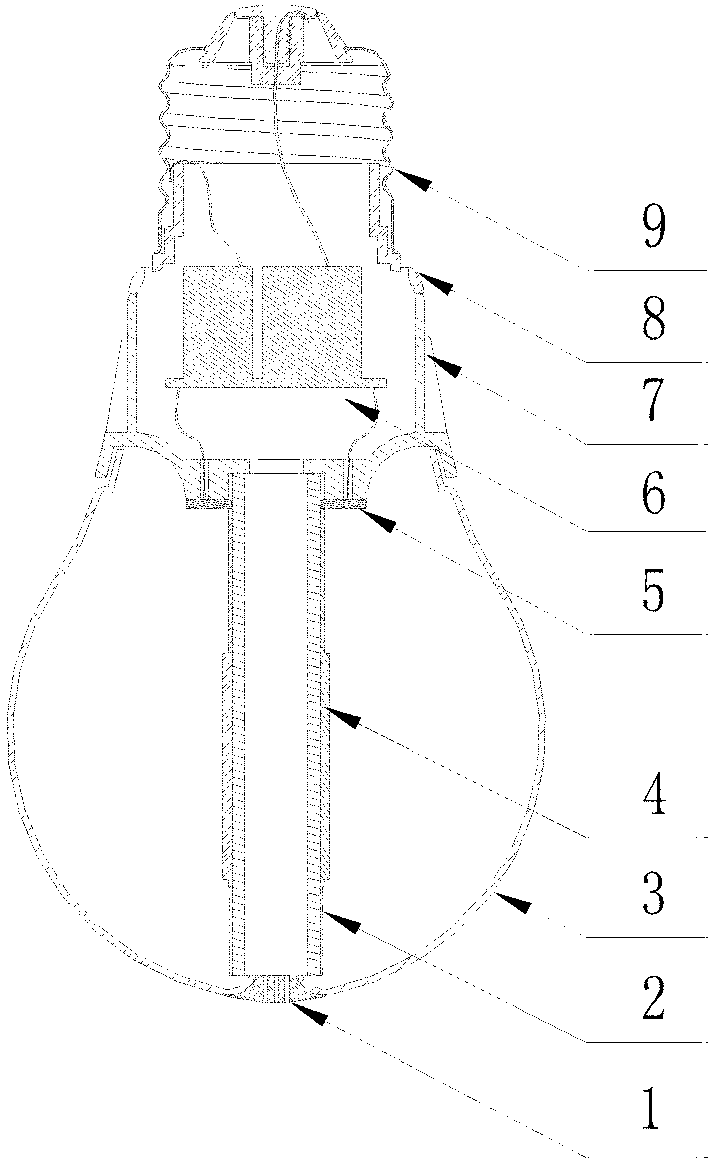

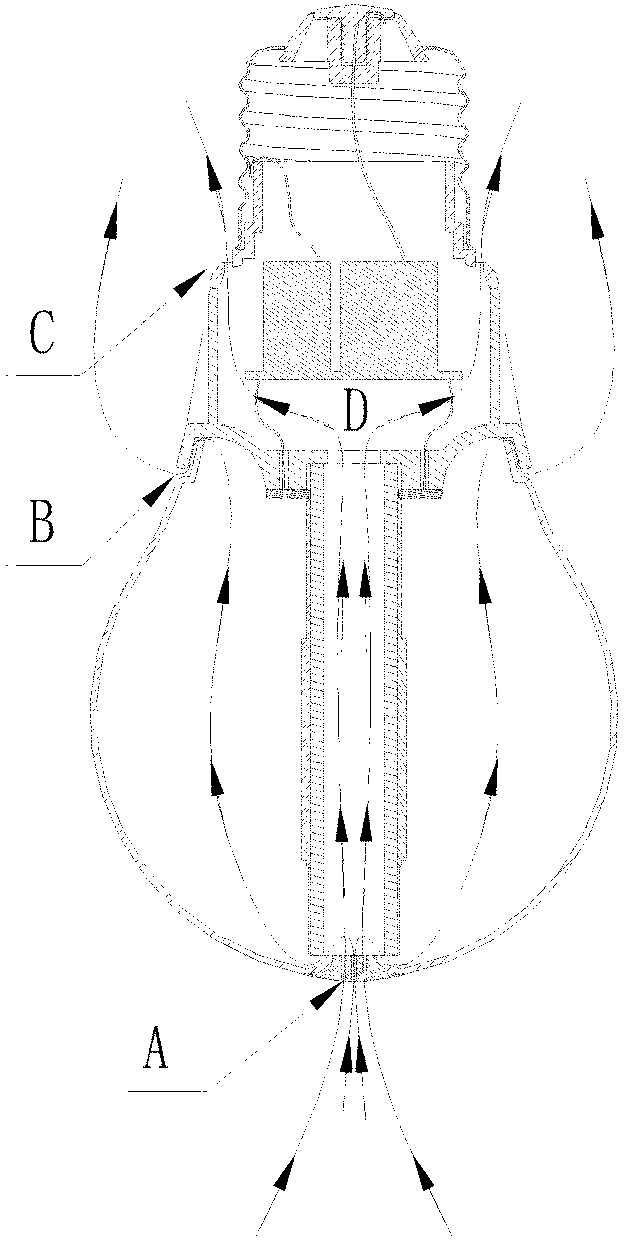

[0015] figure 1 It is a schematic structural diagram of an LED bulb lamp according to an embodiment of the present invention. The LED bulb lamp includes a light-transmitting bulb shell 3 with an airflow net 1; a heat transfer tube 2 with a strip-shaped LED light-emitting tube 4 (for example, a ceramic strip light-emitting tube); the LED light-emitting tube is welded to a PCB5; a drive circuit 6, A plastic lamp housing 8 with air holes (the lamp housing 8 can also be made of other materials); and a radiator 7 .

[0016] The light-transmitting bulb shell 3, for example, can be made of glass, plastic or other composite materials through air blowing, plastic blowing or injection molding. An airflow net 1 with at least one airflow hole is installed on the light-transmitting bulb shell 3 , and further preferably, the airflow net 1 is closely connected with the heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com