Scanning tunnel nanoscale precision measuring instrument

A technology for precision measurement and tunnel scanning, which is applied in the direction of mechanical depth measurement, measuring devices, mechanical measuring devices, etc. It can solve the problems that it is difficult to reach the nanometer level, ultra-precision measurement is time-consuming and labor-intensive, and inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

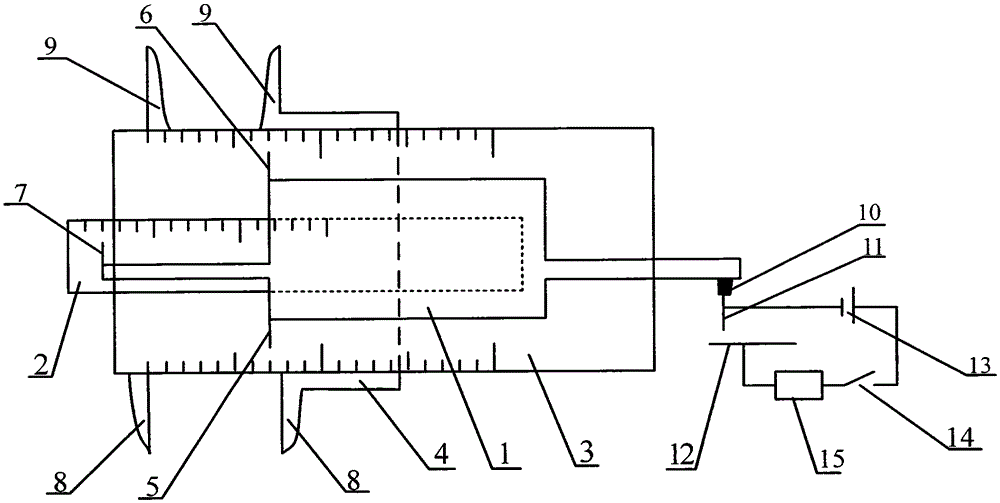

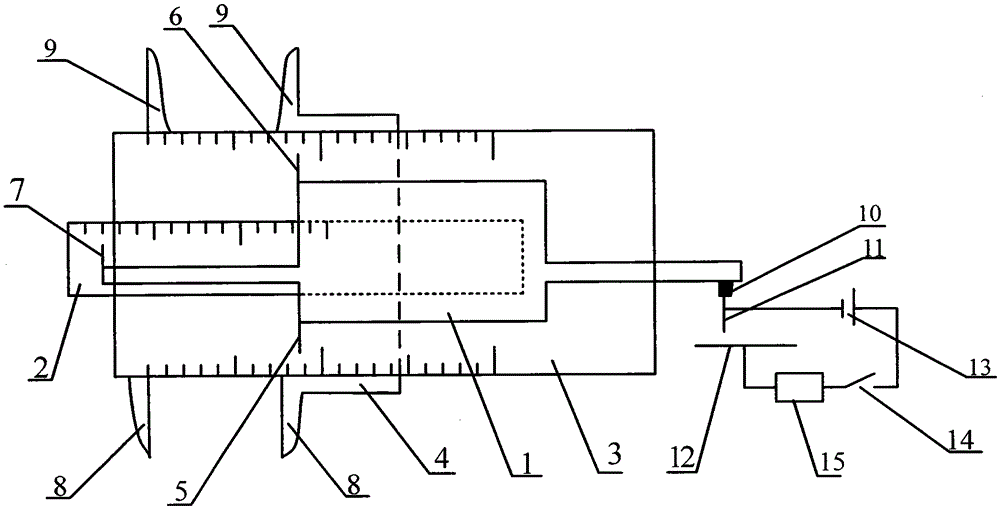

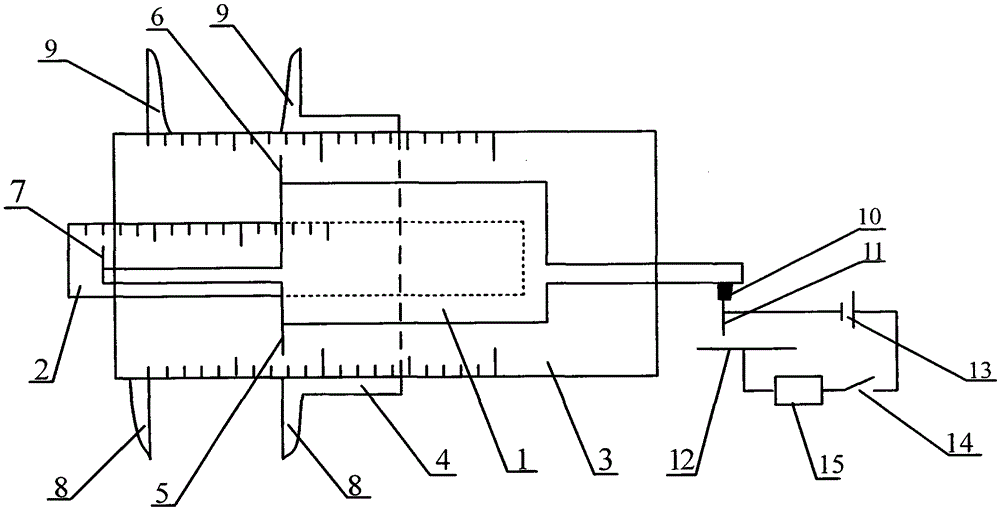

[0009] The structure of the scanning tunnel nanoscale precision measuring instrument of the present invention is as follows: figure 1 As shown, it mainly consists of a precision ruler (1), a depth gauge (2), an inner and outer diameter ruler (3), a caliper (4), an outer diameter pointer (5), an inner diameter pointer (6), a depth pointer (7), an outer diameter Card (8), inner diameter card (9), insulator (10), probe (11), ordered atom plate (12), power supply (13), switch (14) and computer (15). Before using the present invention, place the scanning tunnel nanoscale precision measuring instrument of the present invention on an anti-vibration system, and place the switch (14) in an off state.

[0010] When the inner diameter of a certain pipe needs to be measured, move the caliper (4) to the left so that the two inner diameter cards (9) all extend into the pipe, and then move the caliper (4) to the right to make the two inner diameter cards (9) clamp the inner wall of the pipe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com