Scanning tunnel ultra-precision angle measuring instrument

A scanning tunnel and angle measurement technology, which is applied to measuring devices, instruments, and optical devices, can solve the problems of time-consuming and labor-intensive ultra-precision measurement, inconvenient use, and difficulty in reaching the nanometer level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

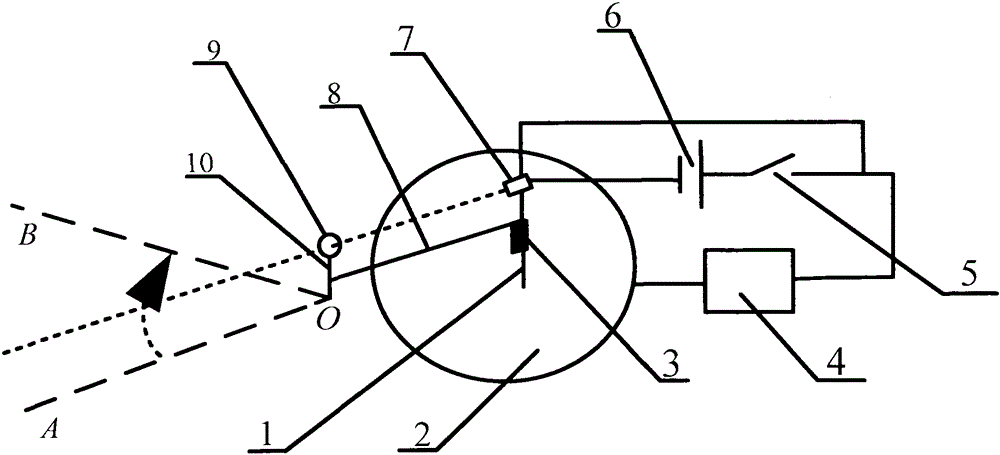

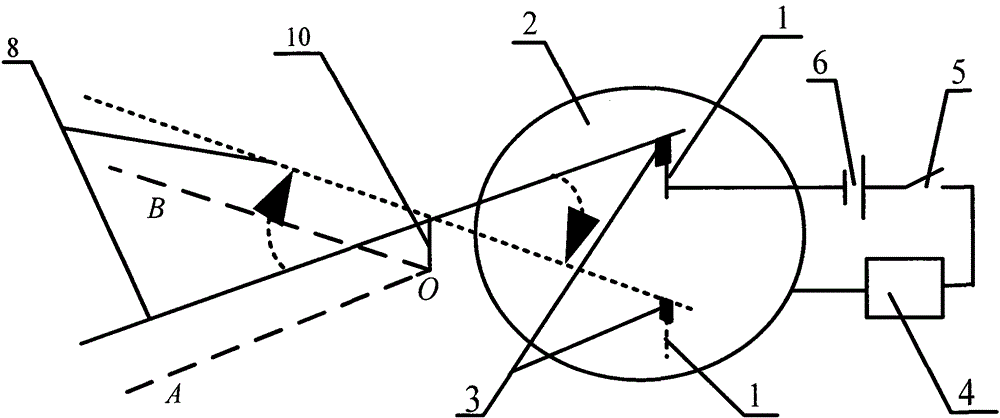

[0007] The structure of the scanning tunnel ultra-precision angle measuring instrument of the present invention is as follows: figure 1 As shown, it mainly consists of a probe (1), an ordered atom plate (2), an insulator (3), a computer (4), a switch (5), a power supply (6), a laser head (7), and a joystick (8) , a light-transmitting mirror (9), and a fixed point (10). Before using the present invention, the scanning tunnel ultra-precision angle measuring instrument of the present invention is placed on an anti-vibration system, and the fixed point (10) is fixed on the apex of the angle to be measured. When using the present invention, turn on the switch (5) earlier, and now the laser head (7) will emit laser lines and pass through the light-transmitting mirror (9) in a straight line, and the light rays will coincide with one side of the angle, and then the computer ( 4) Adjust the numbers on the display to zero. Then rotate the rocker (8) on which the laser head (7) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com