Directional powder feeding device and selective laser melting forming equipment

A technology of laser selective melting and powder feeding device, which is applied in the field of additive manufacturing and can solve the problems of inability to evenly arrange the metal matrix powder and the diamond in the alignment and orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

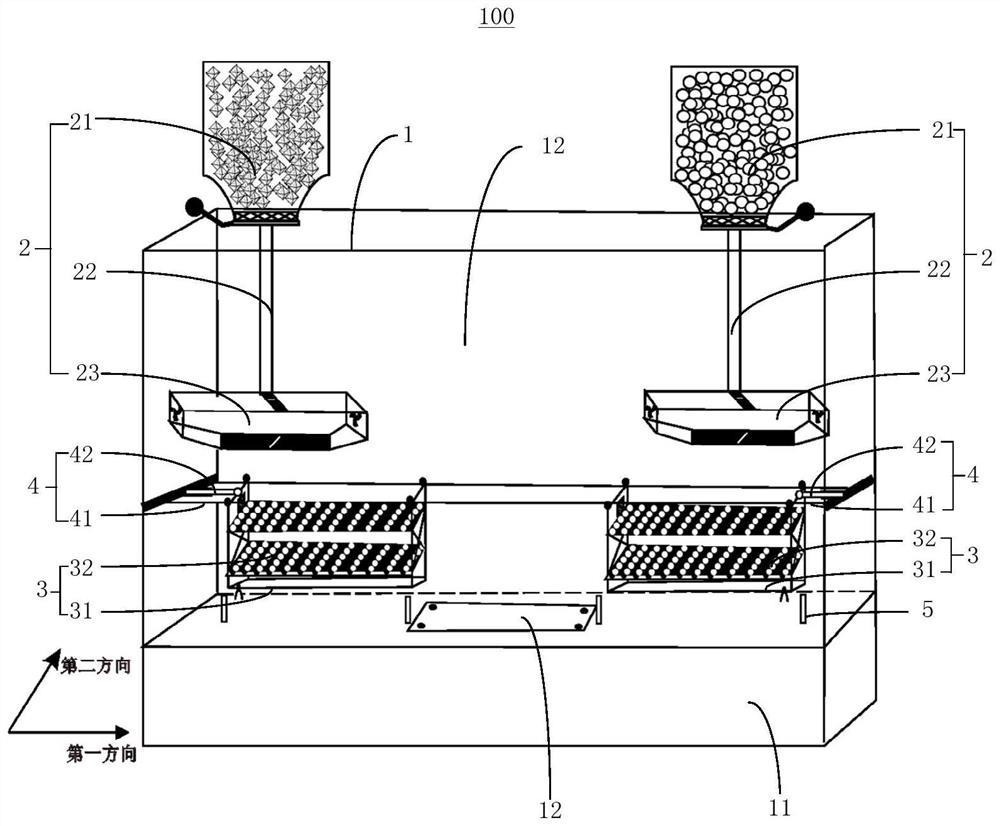

Embodiment 1

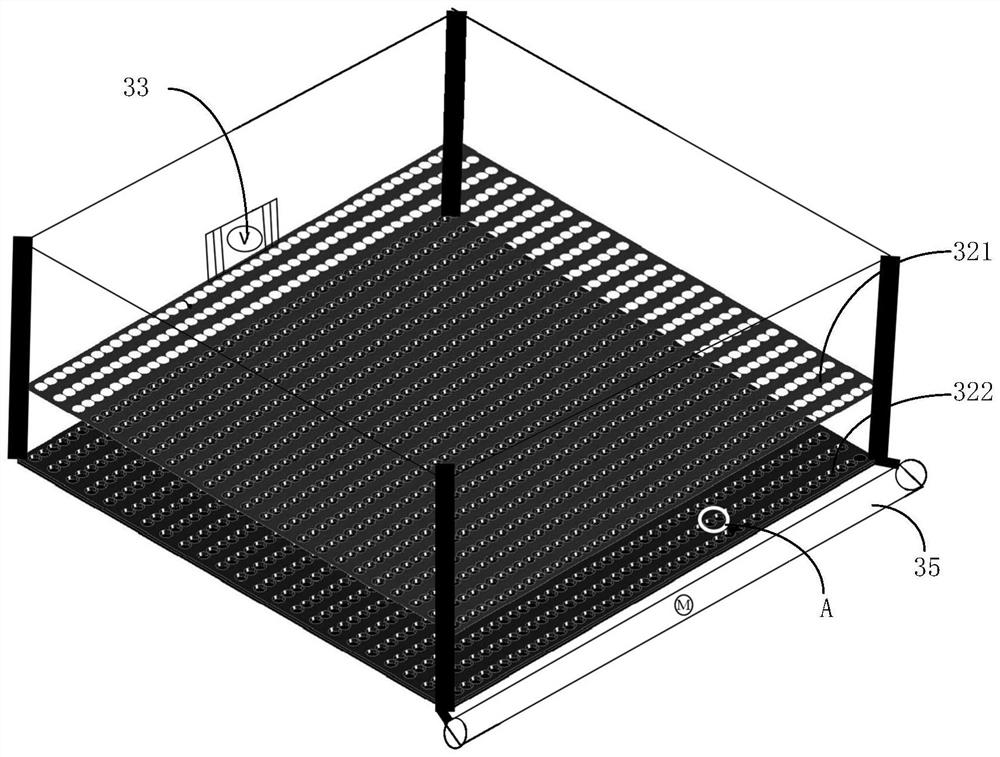

[0065] Example 1, the diamond particle size is 38um, the particle shape is a complete regular octahedron, the matrix metal powder is a commercial CoCrMo alloy, the sphericity of the alloy powder is greater than 99%, and the particle size of the powder used is 38um. The volume proportion of diamond particles is 20%. The workable area of the substrate 13 is selected as a square of 8cm*8cm.

[0066] The directional powder feeding device 100 of the present invention specifically includes the following working steps:

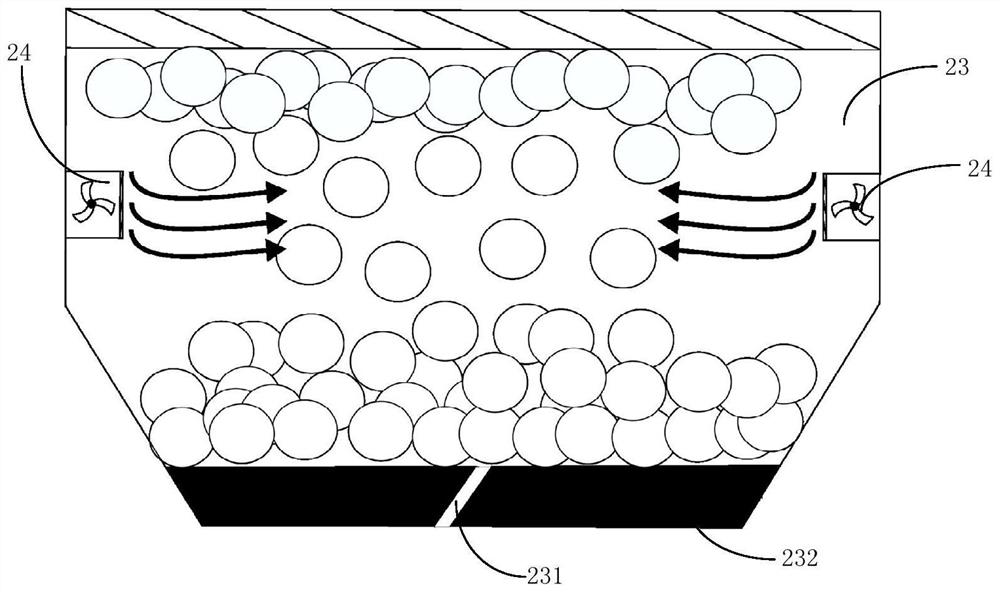

[0067] 1) Load the dry CoCrMo alloy powder into the first powder feeding cylinder 21, and connect the first powder feeding cylinder 21 with the first powder cavity 23 to be laid through the first powder feeding conduit 22;

[0068] 2) The dry diamond powder is loaded into the second powder feeding cylinder 21, and the second powder feeding cylinder 21 is communicated with the second powder cavity 23 to be laid through the second powder feeding conduit 22;

[0069...

Embodiment 2

[0086] Example 2: NiTi alloy is widely used in aerospace and other fields due to its shape memory effect. Generally, NiTi alloy functional parts are formed by laser selective melting technology. Strain shrinkage occurs and the internal stress increases, and the NiTi crystal type cannot meet the phase transformation requirements. Shortening the waiting time of continuous processing is an important means to ensure the good crystal form of functional parts of NiTi alloy. The automatic control fine and orderly directional powder feeding system 2 proposed by the present invention can realize rapid powder feeding.

[0087] In this embodiment, the metal powder used is NiTi alloy, the sphericity of the alloy powder is greater than 99%, and the particle size of the used powder is 42um. The directional powder feeding device 100 to install the system powder feeding device specifically includes the following steps:

[0088] 1) The dry NiTi alloy powder is loaded into the first powder fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com