External insulation contactor

A contactor and external insulation technology, which is applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of affecting the use of electrical products, reducing the service life of insulating parts, and poor temperature resistance of insulating parts, so as to achieve product quality improvement, The high degree of internal metallization improves the effect of temperature resistance and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

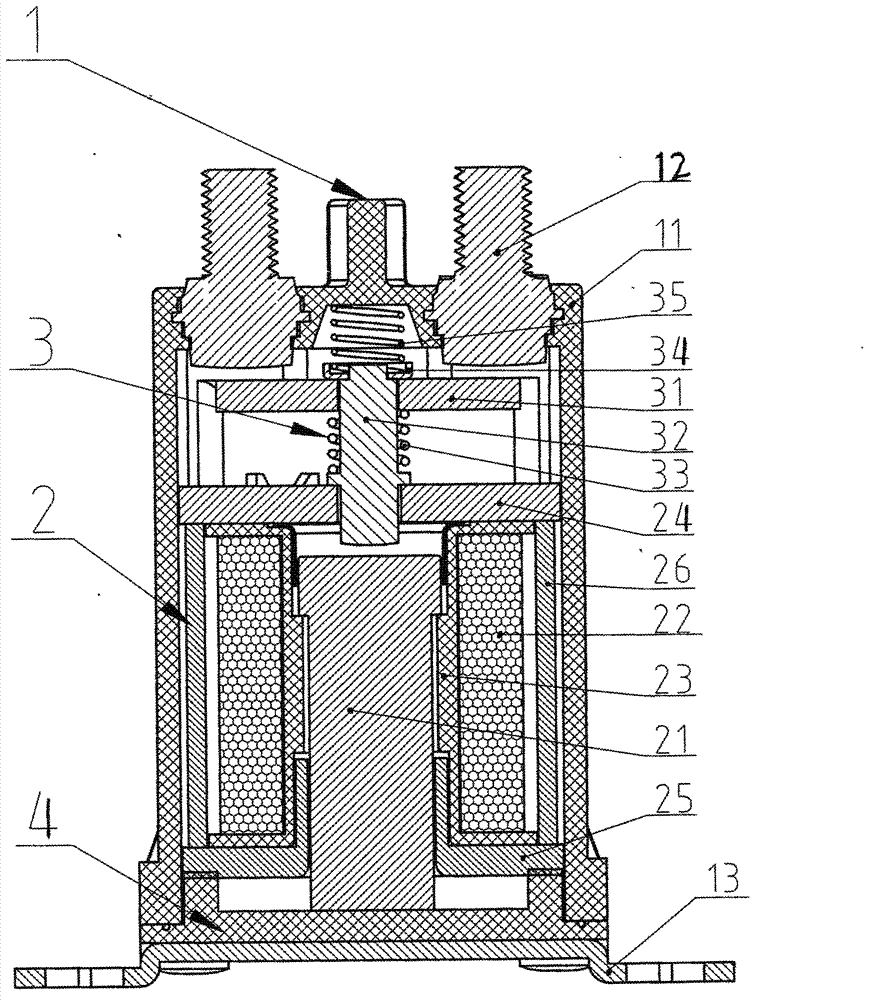

[0009] refer to figure 1 It can be seen that the external insulation contactor of the present invention includes an electromagnetic component 2, a movable contact bridge component 3, and a housing component 1, wherein the housing component 1 includes a shell 11, a fixed electrode 12, and a base 13, and the movable contact bridge component 3 includes a contact bridge 31, push rod 32, overtravel spring 33, upper spring 35, on the contact bridge 31 and push rod 32 of the movable contact bridge member 3, a spring seat 34 is riveted to fix the upper spring 35 (return is better), and An insulator 4 is installed between the electromagnetic component 2 (under which the magnetically conductive plate 25 ) and the base 13 of the housing component 1 .

[0010] Wherein, the insulator 4 also extends to between the casing 11 and the base 13 , and abuts against the bottom of the iron core 21 of the electromagnetic component 2 . The electromagnetic component 2 includes an iron core 21, a coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com