Wire quick connector

A connector and conductive connection technology, applied in the direction of conductive connection, connection, connection end cap, etc., can solve the problems of complicated installation and production connection, complicated structure of connector or terminal, increase wiring process, etc., to shorten the wiring and Off-line time, quick wiring and quick off-line, simplified steps and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

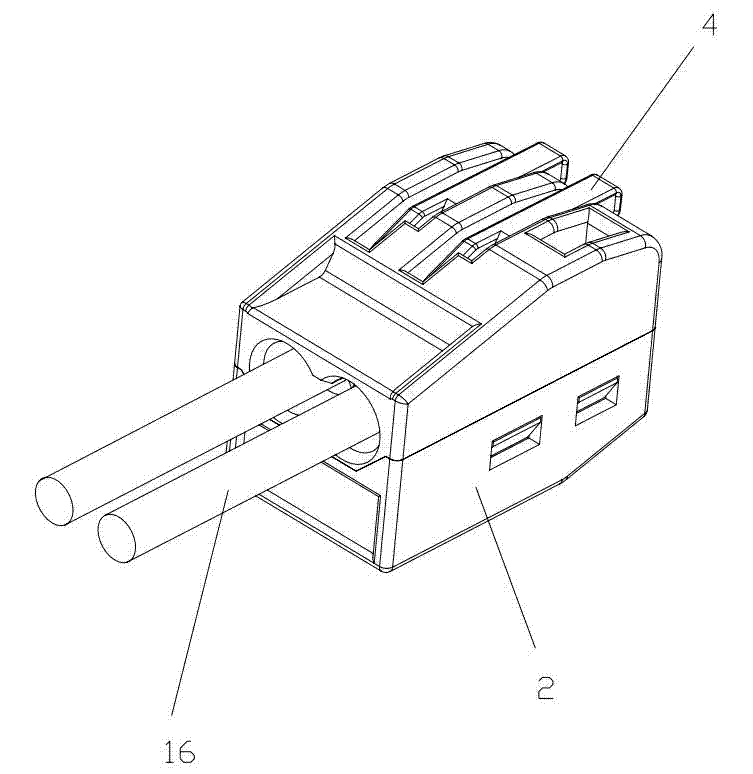

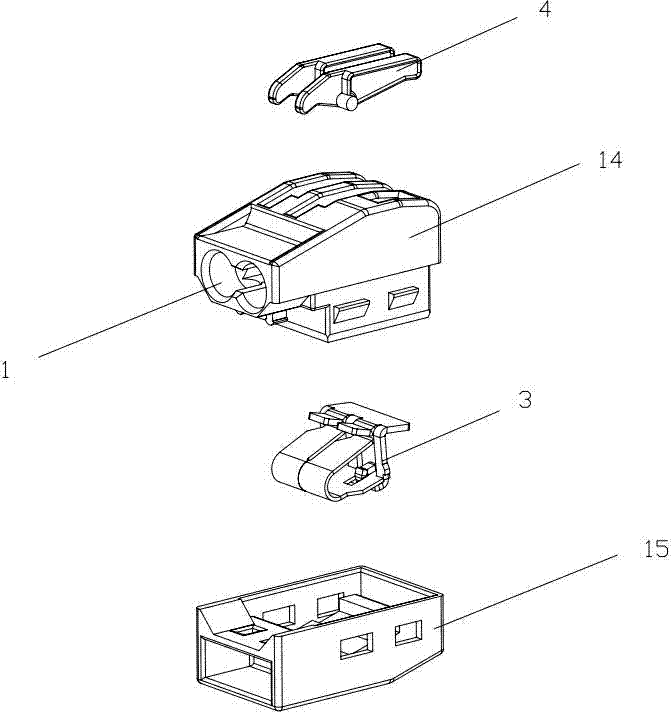

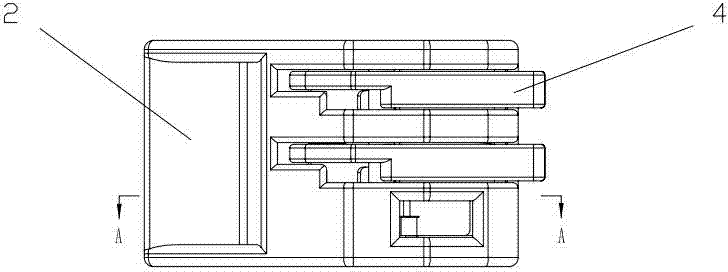

[0032] A wire quick connector described in Embodiment 1 of the present invention, such as 1, figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 13 As shown, it includes an insulating housing 2 with a wire socket 1 and a conductive connecting body 3 arranged in the insulating housing, and also includes a connection / off-line switch 4 that enables the conductive connecting body and the wire to be connected and disconnected. The connecting / disconnecting switch is hinged on the housing, one end of the connecting / disconnecting switch is the handle end 5, and the other end is the pressing end 6. When wiring is required, first lift the connection / offline switch, the connection / offline switch has a self-locking function, and the wire 16 is inserted into the insulating housing from the wire socket. As the wire is gradually inserted, the exposed metal end of the wire is inserted into the conductive connection body and Clamp the bare end of the wire by the conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com