Flue-cured tobacco intensive float breeding hardening-seedling device

A floating seedling raising and seedling hardening technology, which is applied in the fields of application, cultivation, agriculture, etc., can solve the problems of reduced quality, low efficiency, labor and time-consuming and other problems of flue-cured tobacco floating seedling raising, and achieves easy operation, convenient arrangement and storage, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

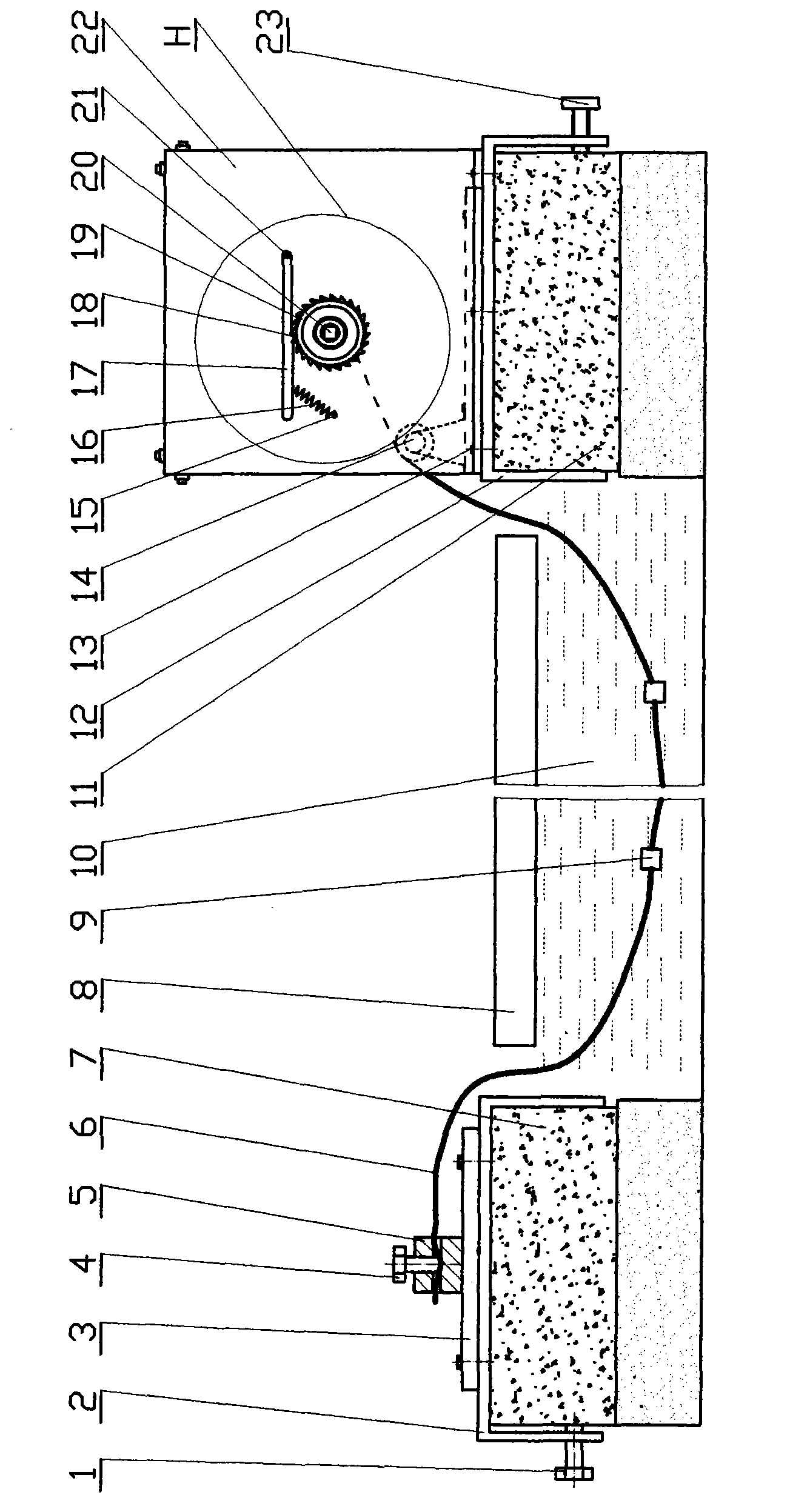

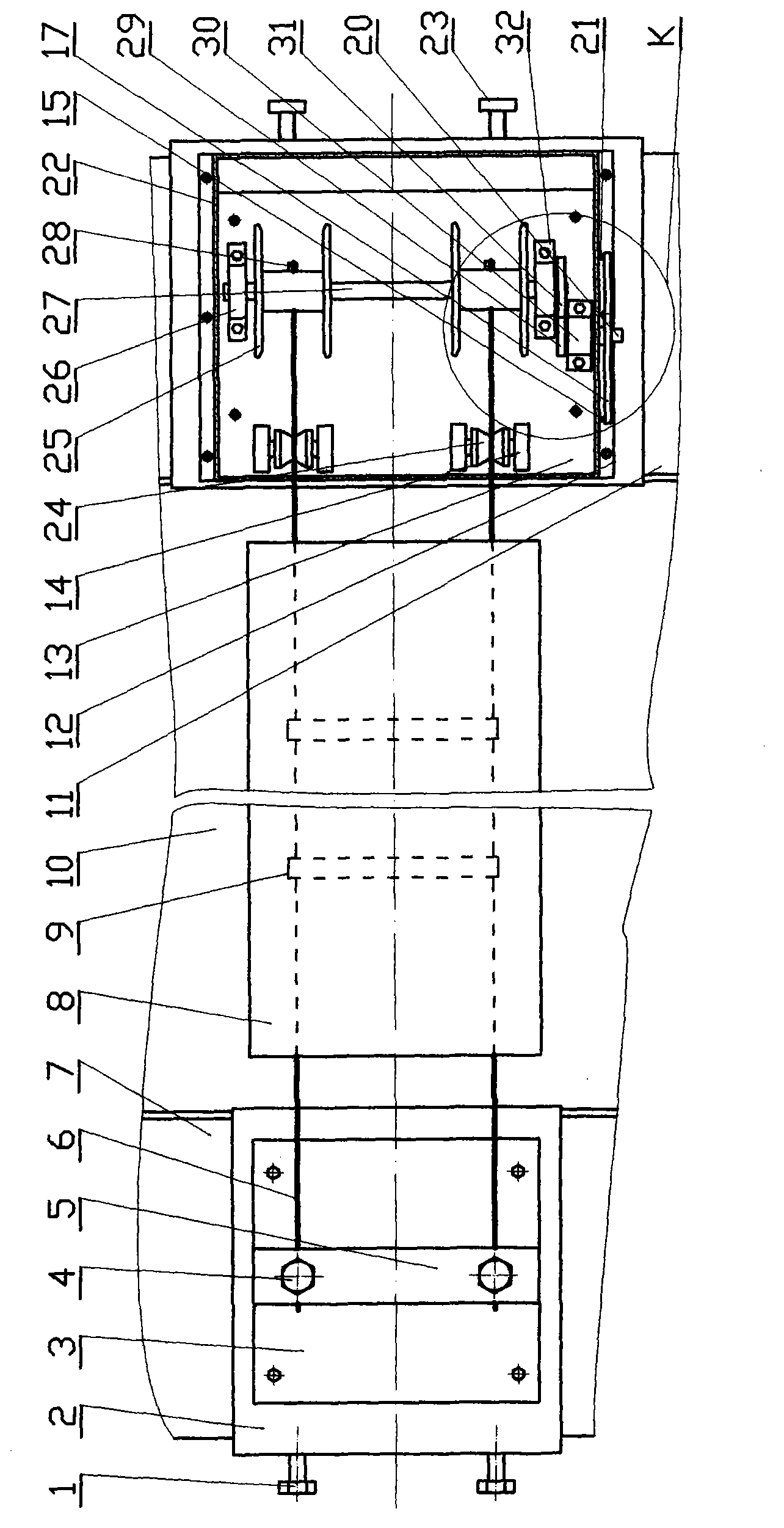

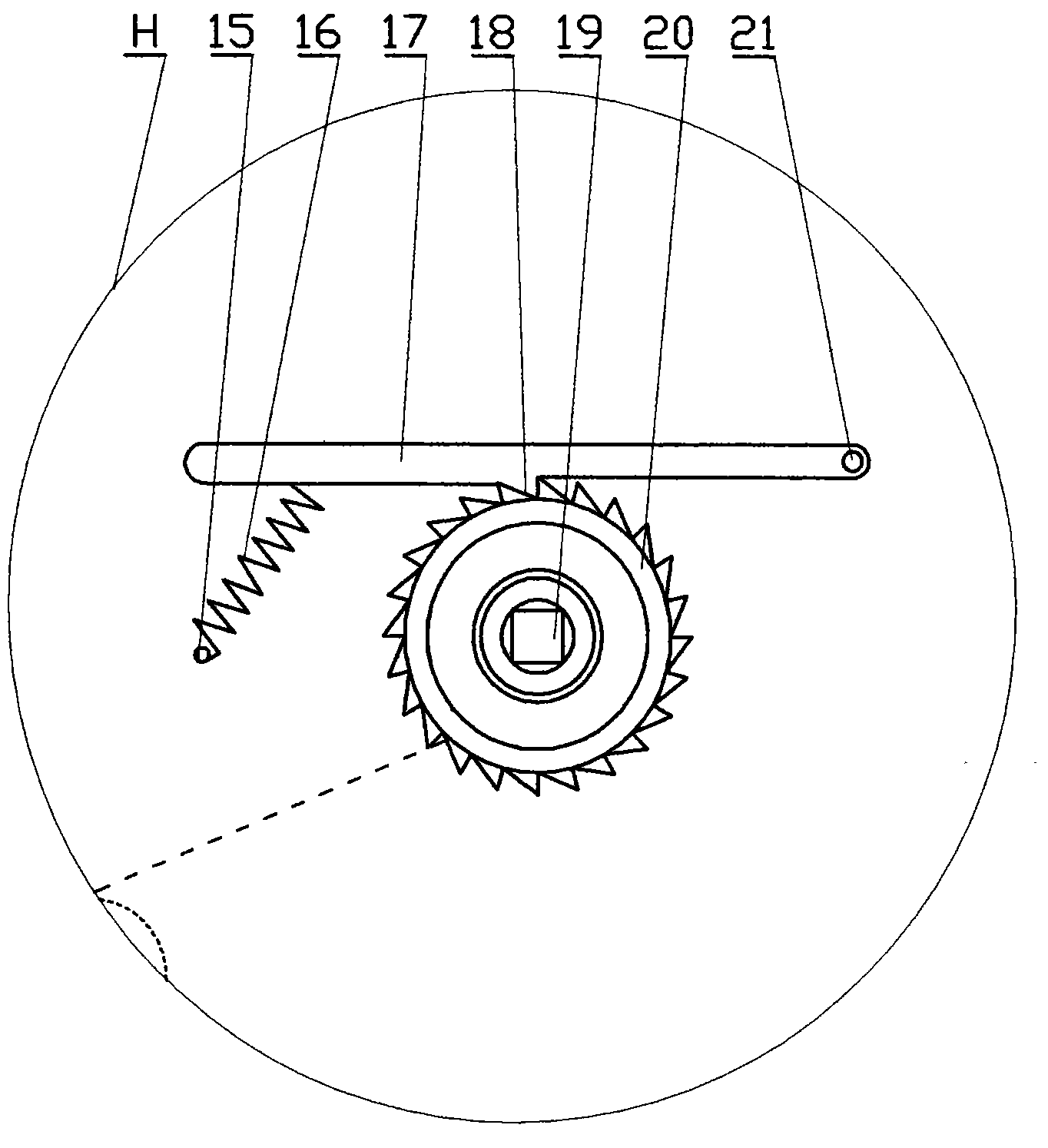

[0020] The present embodiment is made up of floating disc 8, nursery pond 10, fixed assembly, frame assembly, transmission assembly, locking assembly and rotating rope assembly, and floating disc 8 floats in nursery pond 10.

[0021] The fixed component is composed of a fixed card slot 2, a fixed plate 3 and a fixed frame 5. The fixed card slot 2 is in the shape of a channel steel, and is stuck on the left pool stem 7 of the nursery pond, and is fixed by the fixed handwheel 1; the fixed plate 3 is installed on the fixed On the draw-in groove 2, the fixed mount 5 is installed on the fixed plate 3; the fixed mount 5 has more than two rope-threading holes (the number is the same as the traction rope), and is fixed with the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com