Biaxial differential material crusher

A crusher and animal technology, applied in grain processing, etc., can solve the problems of low power consumption and high production efficiency, and achieve the effects of stable operation, improved work efficiency and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

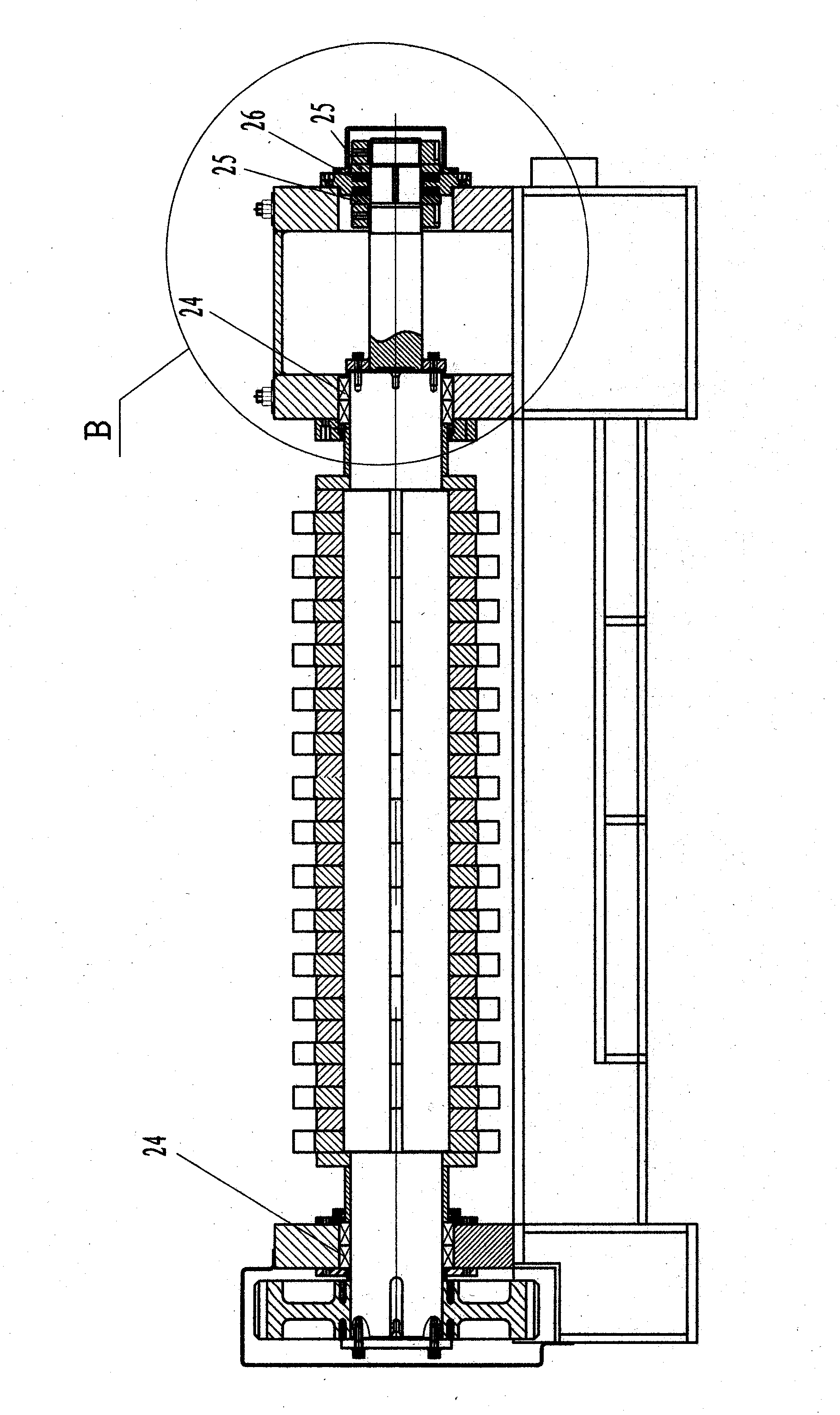

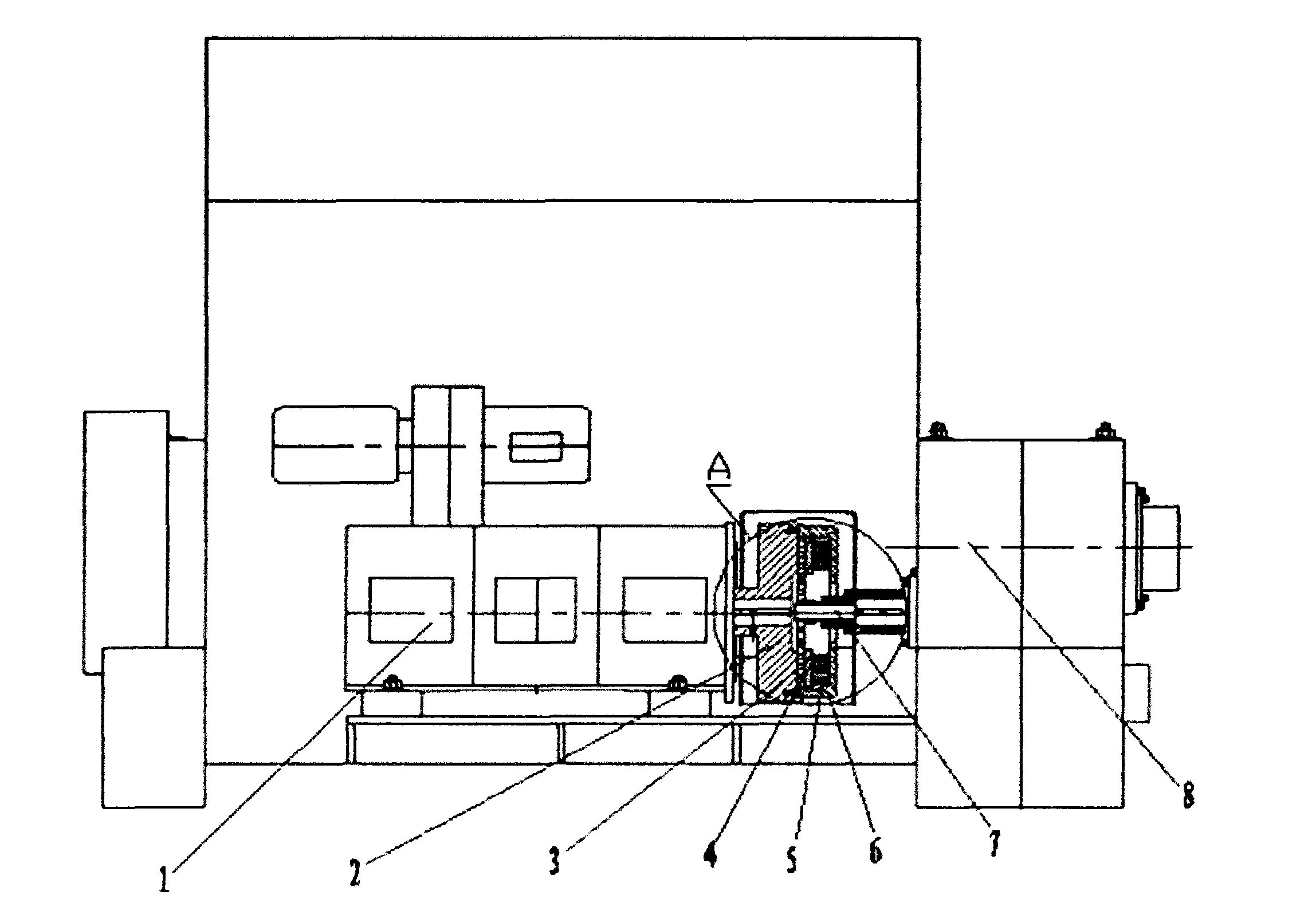

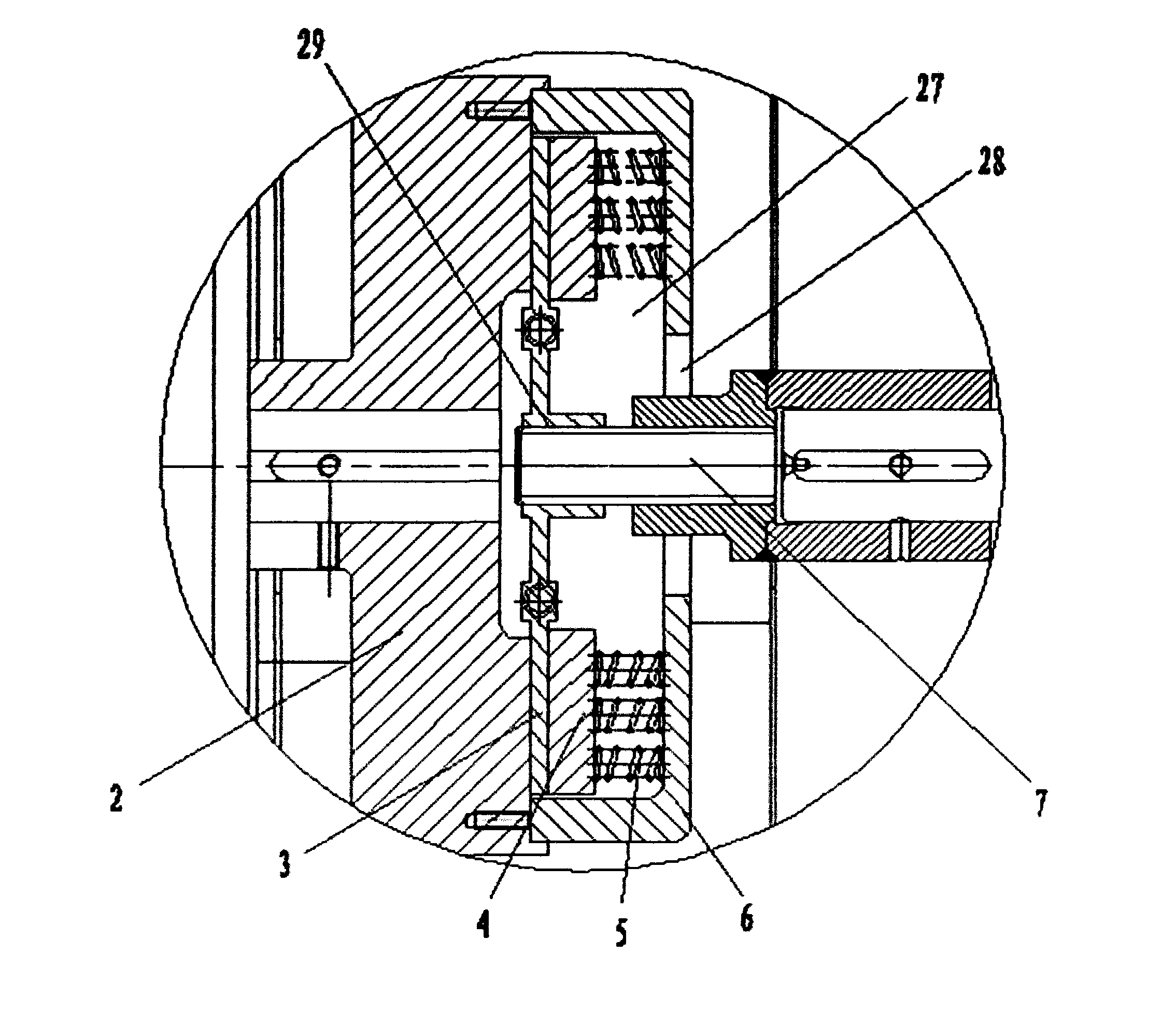

[0024] Such as figure 1 , figure 2 As shown, the present invention includes: a flywheel friction linkage device, a biaxial differential knife stick. The flywheel friction linkage device consists of a flywheel 2, a fixed frame 6, a force transmission friction plate 3, a spring 5, and a pressure block 4. A motor 1 and a reducer 8, the flywheel is fixed on the shaft of the motor, the fixing frame is fixedly connected to the flywheel, a fixing rack cavity 27 is provided inside the fixing frame, and a fixing frame through hole 28 is provided in the middle. It is provided with a force transmission friction plate 3, a pressure block 4 and a spring 5. One side of the force transmission friction plate contacts the friction surface connected to the flywheel, the other side of the force transmission friction plate contacts the friction surface of the connection pressure block, and the other side of the pressure block is provided with Pressing the spring 5 of the compression block, the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com